Understanding the Benefits of a Packaging Centre

At its core, a packaging centre serves as a vital hub within the product distribution network, centralizing various packaging-related tasks to maximize effectiveness and minimize costs. By consolidating resources and expertise, businesses can leverage the substantial benefits that come with a streamlined packaging process.

One of the primary advantages of utilizing a packaging centre is the enhanced efficiency. A packaging centre brings together various elements of the packaging process, from design and prototyping to assembly and distribution, under one roof. This integration reduces turnaround times and improves coordination, ensuring that products are packaged and ready for the market swiftly.

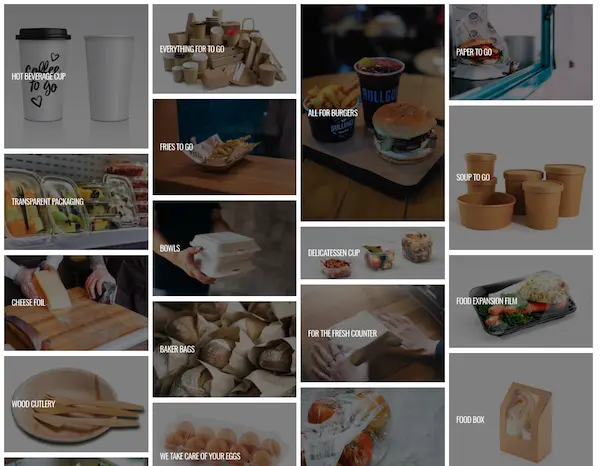

With our network with packaging suppliers along with a huge international network, we provide customizable logistic packaging services as per the needs and requirements of our clients, in order to maintain continuous product development and greatly reduce the spending for packaging solutions.

Economic benefits are also significant. With a packaging centre, companies can take advantage of bulk purchasing for materials and enjoy economies of scale. This translates to cost savings on packaging materials and a reduction in overall production expenses. Additionally, by focusing on the core competencies of packaging, centres often deliver higher quality results, which can lead to fewer returns and enhanced customer satisfaction.

Centralized packaging facilities are often equipped with the latest technologies, offering state-of-the-art automation and customization options. This high degree of technology adoption leads to precise packaging solutions tailored to specific product requirements, enhancing the brand experience for the end consumer.

Lastly, environmental responsibility is an increasingly critical concern for modern businesses, and packaging centres often implement sustainable practices. From using recycled materials to optimizing package designs for reduced waste, packaging centres can help companies align with eco-friendly initiatives and meet consumer demand for sustainability.

Choosing the Right Packaging Centre for Your Needs

Selecting the appropriate packaging centre is crucial for the success of your product delivery system. To ensure you partner with the right facility that meets your specific needs, several key factors must be considered.

Firstly, evaluate the scope of services offered by the packaging centre. It's essential to choose a centre that provides comprehensive solutions, including design support, material selection, and various packaging options that align with your product requirements.

Another consideration is the quality control measures a packaging centre has in place. High-quality standards assure that your products are packaged in a way that maintains integrity and appearance, which is integral for customer perception and satisfaction.

Understanding the centre's commitment to timeliness and dependability is also important. A reliable packaging centre with prompt processing times can be the difference between meeting market demand and facing costly delays.

Consider the centre's flexibility and ability to handle varied production volumes. Whether you need small-scale specialty packaging or large batch handling, the right centre should be able to accommodate your needs without compromising on efficiency or cost.

Finally, assess the packaging centre's dedication to sustainability, ensuring they adopt practices that reflect your company's environmental values, whether through waste reduction, energy efficiency, or eco-friendly packaging materials.

In summary, the choice of a packaging centre should be influenced by their service range, commitment to quality, reliability, scalability, and environmental stewardship. These factors will ensure that the chosen centre aligns with your strategic goals and supports your operational needs effectively.

Advantages and Considerations of Integrated Packaging Services

| Pros | Cons |

|---|---|

| Centralized management of packaging needs | Potential for reduced flexibility with a single provider |

| Cost savings through economies of scale | Risk of dependency on a single service's performance |

| Streamlined communication and simplified logistics | Less control over diverse or specialized packaging options |

| Improved efficiency and turnaround time | Possibility of service interruptions impacting entire operation |

| Consistency in packaging quality and branding | Challenges in managing changes or customizations quickly |

The Role of Packaging Centres in Supply Chain Efficiency

Packaging centres play a pivotal role in enhancing the efficiency of the supply chain. By acting as the intersection where product manufacturing meets distribution, these centres optimize the flow from production to consumer, ensuring that goods arrive safely and on time.

The adoption of advanced tracking systems by packaging centres contributes significantly to supply chain visibility. These systems allow for real-time monitoring of inventory levels, order processing, and delivery status, which is critical for effective supply chain management. As a result, companies can respond promptly to market demands and manage resources more efficiently.

Moreover, packaging centres aid in reducing logistical complexities by providing consolidation services. Products from various suppliers can be received, grouped, and packaged together, thus minimizing the number of shipments required. This leads to reduced transportation costs and a lower carbon footprint.

Additionally, packaging centres can streamline the reverse logistics process. They manage returns efficiently, which is essential for maintaining customer trust and loyalty. By refurbishing, repackaging, and redistributing returned items quickly, packaging centres help preserve product value and reduce loss.

In essence, packaging centres are integral to creating a supply chain that is both robust and responsive. Their strategic position and the services they provide help businesses minimize delays, reduce costs, and ultimately deliver a superior customer experience.

Custom Packaging Solutions at a Packaging Centre

Offering custom packaging solutions is where a packaging centre truly shines. These bespoke services cater precisely to the unique requirements of each product, reinforcing brand identity and enhancing customer engagement.

Innovative design services are a cornerstone of custom packaging. Packaging centres employ skilled designers who work collaboratively with clients to create packaging that not only protects but also promotes the product effectively. This collaboration includes selecting the right materials, textures, and aesthetics that resonate with the target audience.

Moreover, packaging centres offer prototype development. This allows businesses to test and refine packaging concepts before full-scale production, minimizing risks and ensuring the final design is entirely fit for purpose.

The capability to manage short-run production is another benefit. This service is particularly valuable for product trials, limited editions, or niche markets, providing the flexibility to produce smaller quantities without sacrificing quality or consistency.

By delivering these custom packaging options, a packaging centre ensures that businesses can present their products in the best possible way, tailored to their market strategy and consumer expectations.

Integrating Technology and Innovation at Your Packaging Centre

The integration of technology and innovation is a defining feature of modern packaging centres. They implement cutting-edge tools and processes to enhance productivity, precision, and personalization in packaging services.

Advanced digital printing technologies enable high-resolution, vibrant graphics and colors that make products stand out on the shelves. With capabilities such as variable data printing, packaging centres can offer personalized packaging options, creating a unique unboxing experience for customers.

Smart automation and robotics are employed to increase the speed and accuracy of packaging production. These technologies facilitate rapid assembly, packing, and sorting while reducing human error and labor costs.

Software for supply chain and inventory management plays a crucial role in operational efficiency. These systems provide seamless tracking and management of materials and products throughout the production cycle, ensuring that packaging operations are well-aligned with demand and inventory levels.

Through the adoption of these technological advancements, packaging centres help businesses stay ahead in a competitive marketplace by delivering innovative and efficient packaging solutions.

Sustainability and Eco-Friendly Practices in Packaging Centres

Sustainability and eco-friendly practices are becoming increasingly important in packaging centres as environmental concerns rise globally. These centres are adopting green strategies to reduce their ecological footprint while meeting consumer demand for sustainable packaging.

Material choices are at the forefront of these sustainable initiatives. Packaging centres are shifting towards using biodegradable, compostable, or recyclable materials that minimize the impact on the planet. These materials reduce reliance on fossil fuels and decrease the amount of waste in landfills.

Implementing energy-efficient machinery and processes is another way packaging centres are reducing their environmental impact. By optimizing production lines and investing in energy-saving technologies, they not only cut down on energy use but also lower operational costs.

Waste management strategies like upcycling and recycling programs within packaging centres also contribute to more sustainable practices. By finding new ways to use scrap materials and recycling waste products, they are able to close the loop and reduce overall waste.

Through these measures, packaging centres are not only improving their sustainability but also helping their clients meet their own green goals, creating a ripple effect that promotes broader environmental responsibility across industries.

Navigating the Services Offered by a Packaging Centre

Navigating through the array of services provided by a packaging centre can be an intricate task, but understanding these services helps in harnessing the full potential of what the centre has to offer.

Comprehensive service offered by many packaging centres includes consultation and project management. Experts guide clients from the initial concept through to the final delivery, ensuring a seamless transition at each stage of the packaging process.

A vital service that packaging centres offer is logistics and warehousing. This involves the storage of both raw materials and finished products, coupled with an organized system for inventory management and order fulfillment.

Packaging centres may also provide labeling and barcoding services. This facilitates easier tracking and management of products throughout the supply chain, enhancing the transparency and accountability of product distribution.

A key service that is often overlooked is the after-sales support and customer service offered by the packaging centre. This includes assistance with any issues that arise after the packaging solutions have been delivered and implemented.

By exploring and leveraging the diverse services offered by a packaging centre, clients can enjoy a fully optimized packaging experience that is tailored to meet their specific needs and objectives.

Cost-Effective Packaging Strategies with a Packaging Centre

Developing cost-effective packaging strategies is essential for businesses looking to improve their bottom line, and packaging centres play a vital role in facilitating these economical solutions.

One strategy employed by packaging centres to reduce costs is the optimization of packaging design. By analyzing the product dimensions and shipping requirements, the centre can create packages that use the least amount of material while still ensuring product protection, thus saving on material costs.

Bulk procuring of supplies is another area where packaging centres can drive cost savings. Leveraging their large network and purchase volumes, they are able to negotiate better prices for packaging materials, a benefit that gets passed on to the client.

Packaging centres also help reduce costs through efficient production processes. Utilizing automated systems and streamlined operations minimizes labor costs and decreases the potential for costly errors or rework.

Lastly, packaging centres may offer flexible pricing plans. This gives businesses the ability to choose services that match their budgets, whether it's a one-off project or an ongoing partnership.

By implementing these strategic approaches, a packaging centre can help clients achieve a delicate balance between cost-cutting and maintaining high-quality packaging standards.

Building a Long-Term Partnership with a Packaging Centre

Establishing a long-term partnership with a packaging centre can lead to numerous benefits for a business, including consistency in quality, efficiency in production, and cost savings over time.

Building such a partnership starts with clear communication of goals and expectations. This ensures that the packaging centre aligns with your company's objectives and can adjust its services to meet evolving needs.

A strong partnership also hinges on the packaging centre's ability to offer scalability. As your business grows, the centre should have the capabilities to upscale the services and support increasing demand without interruptions.

Regular feedback and reviews are integral for continuous improvement. Regular meetings and assessments allow for the discussion of potential enhancements in the packaging process and troubleshooting any issues that arise.

Trust and reliability are the foundations of any long-term relationship. Select a packaging centre that has a proven track record of delivering on promises and maintaining stringent quality standards. This builds confidence and ensures a dependable flow of services.

In conclusion, fostering a long-term partnership with a packaging centre not only facilitates smoother operations but also nurtures an environment where collaborative innovation can thrive, ultimately leading to greater success for both parties.

Measuring the Impact of a Packaging Centre on Your Business

Assessing the impact of a packaging centre on your business involves a close examination of various performance indicators that highlight the value added by the partnership.

One key metric is the reduction in product damage rates. Effective packaging solutions provided by the centre should result in fewer damaged goods, which can be quantified by comparing historical damage figures against current data.

Another important measure is the speed of packaging and distribution. The efficiency of a packaging centre can be gauged by tracking the lead times from product completion to market delivery, noting any improvements since the onset of the partnership.

Cost savings are a compelling indicator of impact. Scrutinize your financial reports to identify any decreases in packaging-related expenses, considering both direct costs, like materials, and indirect costs, such as labor or waste disposal.

Customer satisfaction levels can also reflect the effect of a packaging centre's services. Surveys and reviews may reveal enhanced consumer appreciation for the packaging quality, design, or sustainability, which can translate to stronger brand loyalty and repeat business.

Analyzing these aspects will provide concrete evidence of the positive changes brought about by the packaging centre, enabling your business to make data-driven decisions for further strategic development.

The Future of Packaging: Trends in Packaging Centres

Exploring emerging trends within packaging centres provides insight into the future of packaging and prepares businesses to adapt to forthcoming changes in the industry.

Personalization and customization are becoming increasingly sought after, driven by consumer desire for unique and personalized products. Packaging centres are expanding their capabilities to accommodate this trend, using advanced digital printing techniques to offer a greater degree of customization.

The rise of e-commerce has led to a shift in packaging priorities, with a focus on durability and the unboxing experience. Packaging centres are responding to this by designing innovative packaging that is both robust for transit and visually appealing to the end user.

Smart packaging featuring interactive elements such as QR codes, NFC chips, or augmented reality is on the rise. These technologies not only enhance customer engagement but also provide businesses with valuable consumer data.

Sustainable materials and designs will continue to be at the forefront. Packaging centres are exploring new, eco-friendly materials and processes that lessen environmental impact while maintaining the functionality and aesthetics of packaging.

In summary, packaging centres are evolving to meet modern demands by embracing technology, personalizing experiences, adapting to e-commerce growth, integrating smart elements, and prioritizing sustainability.

Maximize Efficiency with a One-Stop Packaging Centre Solution

What does a one-stop packaging centre offer?

A one-stop packaging centre offers a comprehensive range of services, including package design, material procurement, prototyping, production, and logistic support. It enables streamlined operations from conception to distribution, reducing turnaround times, and improving overall efficiency.

How can working with a packaging centre reduce costs?

Partnering with a packaging centre can lead to cost reductions through bulk material purchases, economies of scale, and the optimization of packaging design to minimize waste. Additionally, the use of automated processes reduces labor costs and errors, contributing to more economical packaging solutions.

Can a packaging centre provide custom packaging solutions?

Yes, packaging centres specialize in creating custom packaging solutions tailored to specific product requirements. They offer innovative design, prototype development, and the flexibility to manage short-run productions, ensuring that the packaging reflects the brand identity and appeals to the target audience.

What role do packaging centres play in supply chain efficiency?

Packaging centres are pivotal in boosting supply chain efficiency by centralizing packaging-related tasks, utilizing advanced tracking systems for greater visibility, offering consolidation services to reduce shipping complexity, and effectively managing returns to maintain customer satisfaction and loyalty.

Are eco-friendly practices implemented in packaging centres?

Yes, many packaging centres prioritize sustainability by using eco-friendly materials like biodegradable and recyclable options, employing energy-efficient machinery, and implementing waste management strategies like upcycling and recycling to minimize environmental impact.