Understanding the Basics of Packaging Technology

Packaging technology is an essential aspect of modern commerce, vital for protecting products, extending their shelf life, and providing important information to consumers. At its core, packaging technology encompasses a range of disciplines and solutions designed to encase a variety of goods in materials that ensure safe transportation, storage, and delivery. With an ever-expanding array of products being developed, the need for innovative packaging solutions is crucial.

Materials play a key role in the function of packaging. Traditional materials such as glass, metal, paper, and plastics continue to evolve, becoming more sophisticated over time. Modern packaging materials are often tailored to the specific needs of products, with features such as moisture barriers, UV protection, and anti-tampering elements. The choice of material not only affects the product's safety but also its sustainability and recycling capabilities.

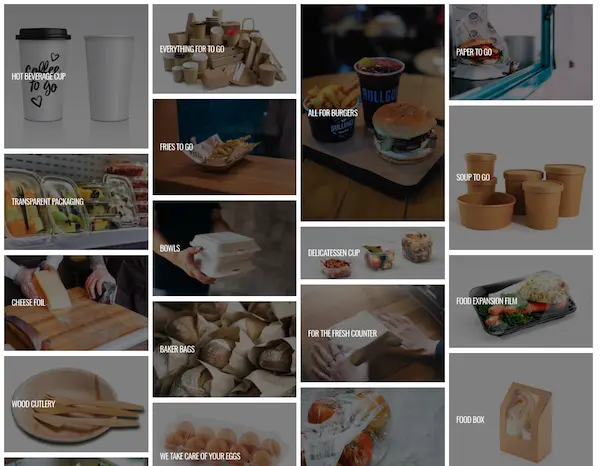

With our network with packaging suppliers along with a huge international network, we provide customizable logistic packaging services as per the needs and requirements of our clients, in order to maintain continuous product development and greatly reduce the spending for packaging solutions.

Another fundamental component is the design process, where the form and structure of the packaging are developed. This involves considerations for aesthetic aspects, which influence consumer appeal, as well as practical design for usability and efficiency in storage and transport. Advancements in computer-aided design (CAD) have streamlined this process, enabling designers to create more complex and user-friendly packaging designs faster than ever.

In summary, understanding packaging technology starts with recognizing the interplay between material science, design innovation, and the functionalities required for various products. As technology advances, these elements merge to form smarter, more sustainable packaging solutions that continue to revolutionize the industry.

Exploring Cutting-Edge Materials in Modern Packaging

The relentless quest for innovation in packaging technology has led to the exploration and adoption of cutting-edge materials that offer superior performance and sustainability. These materials are not just about keeping up with trends but also about pioneering changes that can significantly reduce the environmental impact while enhancing the protection and functionality of packaging.

Bioplastics are gaining traction as a viable alternative to conventional plastics. Derived from renewable biological resources, these materials are designed to biodegrade more efficiently, thereby contributing to a reduction in plastic pollution. Innovations in bioplastics include materials such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), which offer comparable qualities to petrochemical plastics yet ensure a lesser environmental footprint.

Another area of advancement is the development of active packaging materials. These are engineered to interact with the contents or the environment, offering benefits such as antimicrobial properties, or extending shelf life by controlling oxygen or ethylene levels inside the packaging. Incorporating substances like oxygen scavengers or moisture absorbers directly into the packaging material dramatically boosts product longevity and freshness.

Edible packaging materials also represent an innovative frontier in the packaging industry. Made from natural, consumable ingredients, these materials can be eaten along with the product they cover, thus eliminating waste entirely. Promising examples include seaweed-based films and coatings that dissolve in water.

Lastly, advancements in material science have led to the creation of smarter, more adaptable packaging. This includes the use of graphene, a material prized for its exceptional strength, thermal conductivity, and flexibility. It is poised to transform packaging with its ability to create ultra-thin, yet durable barriers against moisture and gases, while also lending itself to smart packaging applications.

"The future of packaging technology is bright, with materials that push the boundaries of functionality, safety, and environmental responsibility."

In conclusion, the exploration of novel materials represents a dynamic sector within the realm of packaging technology. From biodegradable options to smart, responsive substances, these materials are not just shaping the future of packaging but are also setting new standards for industry practices.

Assessing the Impact of Novel Packaging Innovations

| Pros | Cons |

|---|---|

| Reduction in packaging material waste | Increased complexity of packaging production |

| Enhanced preservation of food quality and shelf life | Potential increase in product cost due to new technologies |

| Implementation of biodegradable materials | Dependency on advanced technology possibly not available globally |

| Smart packaging with connectivity for tracking and quality monitoring | Concerns regarding consumer privacy and data protection |

| Improved packaging designs for better consumer convenience | Need for businesses to invest in new machinery and training |

Smart Packaging: Integrating Technology for Enhanced Functionality

Smart packaging is revolutionizing the packaging sector by incorporating technology for improved product experiences and functionalities. This integration elevates conventional packaging to interactive and informative platforms that can engage consumers and offer manufacturers real-time data insights.

One vital smart packaging component is QR codes and NFC tags. When scanned with a smartphone, these codes link customers to a wealth of information such as origin, ingredients, and authenticity verification. They also enable brands to provide consumers with a more dynamic and personalized relationship with the product through promotions and additional product-related content.

Temperature-sensitive inks and labels are a key feature in the food and pharmaceutical industries. These intelligent elements change color or appearance to indicate if the product has been exposed to temperatures outside a safe range, thus ensuring consumer safety and preventing spoilage.

RFID technology is a leap forward within smart packaging. These tags store and remotely retrieve data via radio waves, allowing for enhanced supply chain visibility and inventory management. RFID tags are particularly useful in automating checkout processes, reducing labor costs, and preventing theft.

Finally, smart packaging adopts sensors capable of monitoring various factors like freshness, pH levels, and CO2 emissions. This integration is crucial in ensuring product integrity and providing valuable insights into consumer usage, ultimately aiding in the design of more effective packaging solutions.

In essence, smart packaging is at the forefront of integrating state-of-the-art packaging technology to foster a safer, more informative, and interactive consumer experience, as well as to streamline logistics and distribution processes for manufacturers.

Sustainable Solutions: Eco-Friendly Advances in Packaging

The call for environmental preservation has steered the packaging technology industry toward sustainable solutions. Advanced eco-friendly packaging options are now available, addressing the urgent need to reduce waste and minimize ecological impact.

One significant development in this realm is the adoption of compostable packaging. Made from plant-based materials like cornstarch and sugarcane, these packaging types decompose naturally within a compost environment, transforming into nutrient-rich soil. Compostable packaging materials have the added advantage of reducing the reliance on fossil fuels, offering a double benefit for sustainability.

Lightweighting is another strategy being employed to enhance sustainability in packaging. By reducing the amount of material required to manufacture packaging, lightweighting lowers energy consumption and greenhouse gas emissions throughout the manufacturing process, also lessening transportation fuel use and costs.

The surge in upcycling practices is contributing to a more sustainable packaging industry as well. Upcycling involves creatively repurposing by-products or waste materials into new, valuable products, thus extending their lifecycle and reducing the amount of waste generated.

Moreover, many companies are now embracing a circular economy approach by implementing closed-loop recycling systems. In these systems, packaging is designed to be collected, recycled, and reused in a never-ending cycle, which minimizes the need for virgin materials and reduces waste substantially.

Conclusively, these eco-friendly advances reflect a transition toward more sustainable practices within the packaging industry. Through compostable materials, lightweighting techniques, upcycling innovation, and closed-loop recycling, the sector is not only responding to consumer demands for sustainability but also contributing to a healthier planet.

Personalization and Customization in Packaging Design

In today's market, the value of personalization and customization in packaging design cannot be overstated. Brands are increasingly leveraging these aspects of packaging technology to connect with consumers on a more individual level, enhancing the unwrapping experience and fostering customer loyalty.

Digital printing technology has been instrumental in this shift. It allows for high levels of customization without the need for expensive and time-consuming traditional print methods. Brands can now create limited edition packaging runs, seasonal designs, or even individualized packaging features that address the consumer directly, such as their name or a personalized message.

Interactive packaging is also gaining ground, wherein consumers can engage with the packaging through their digital devices. This might include augmented reality experiences, where scanning a package can bring a product to life on screen, offering not just information but also entertainment and deeper brand engagement.

Companies are recognizing the effectiveness of user-generated content, encouraging consumers to share their own designs for a chance to see them produced on actual product packaging. This strategy not only fosters a community around the brand but also provides an abundance of authentic marketing content.

In concluded analysis, personalization and customization are key elements driving innovation in packaging design. They empower brands to create unique experiences for consumers, leading to stronger emotional connections and an enhanced brand image.

The Role of Automation and Robotics in Packaging

Automation and robotics have become indispensable in the rapidly evolving packaging industry. These technologies are pivotal in boosting efficiency, precision, and reducing labor costs, particularly in repetitive and high-volume tasks.

Robotic systems are now able to perform a myriad of tasks in the packaging process, from picking and placing items to more complex actions like assembly and labeling. These robots are equipped with advanced sensors and vision systems, allowing them to handle a diverse range of packaging designs and materials with incredible accuracy.

Collaborative robots—or cobots—are designed to work alongside human operators, providing a safe and flexible solution to increase productivity. Cobots can easily be reprogrammed for different tasks, making them adaptable to various packaging needs. This is particularly valuable in industries where customization and quick turnarounds are crucial.

Automation extends to packaging machinery that can autonomously adjust operating parameters in real-time, optimizing the packaging process for speed and material usage. This smart machinery can contribute significantly to reducing waste and energy consumption, supporting more sustainable packaging operations.

With the integration of the Internet of Things (IoT), robotic packaging systems are becoming more interconnected, enabling seamless communication between different stages of the packaging line. The resulting data collected can be used to further refine operations, predict maintenance needs, and enhance overall production strategies.

In summary, the adoption of automation and robotics in packaging is transforming the industry, yielding high-speed, efficient, and sustainable operations. As these technologies continue to advance, we can expect to see further enhancements in the speed and sophistication of packaging technology capabilities.

Advancements in Packaging Printing Techniques

As a significant aspect of packaging technology, advancements in printing techniques have greatly influenced both the functionality and aesthetic appeal of packaging. Recent developments are focused on enhancing the quality and efficiency of printing methods while also reducing their environmental footprint.

Innovations in digital printing have led to a surge in print-on-demand capabilities. Packaging can now be printed faster, with lower setup costs and with the ability to implement changes on the fly. This agility offers brands the flexibility to produce small batches for testing or limited editions, minimizing waste from unsold inventory.

Another revolutionary technique is 3D printing, which has stepped beyond prototyping into the realm of producing finished packaging products. 3D printing enables packaging to be constructed layer by layer, opening up possibilities for designs that were previously too complex or costly to manufacture through traditional methods.

Flexography, a form of rotary printing, has seen enhancements with the introduction of photopolymer printing plates and precise color matching systems. These advancements allow for higher quality prints and speedier production times, ultimately benefiting rapid turnaround and high-volume packaging applications.

Furthermore, UV-curable inks have made an impact in the packaging industry. They dry instantly when exposed to ultraviolet light, allowing for faster processing and a reduction in the use of harmful solvents. This not only improves efficiency but also contributes to more sustainable printing practices.

In conclusion, the field of packaging printing is experiencing a dynamic evolution, driven by the desire to achieve greater customization, speed, and sustainability. These technological leaps forward in printing are allowing brands to present their products in innovative, eye-catching ways that align with consumer values and market demands.

Nanotechnology in Packaging: A Game-Changer

Nanotechnology is altering the packaging landscape by infusing materials with significantly improved properties. At the nanoscale, particles behave differently, providing packaging technology with unprecedented functionality.

One area where nanotechnology has made remarkable inroads is in enhancing barrier properties. Nanoparticles can be integrated into packaging films to create a denser matrix, vastly improving the barrier against moisture, gases, and light. This enhancement can dramatically extend the shelf life of perishable goods without altering the package's look or feel.

Antimicrobial packaging is another promising application of nanotechnology. By incorporating silver nanoparticles, known for their natural antimicrobial properties, packaging can actively help in reducing spoilage and contamination by pathogenic microbes, ensuring food safety and quality.

Nanotechnology also offers advances in packaging strength and durability. Adding nanoparticles like nanoclays or graphene can reinforce packaging materials, making them stronger while maintaining, or even reducing, weight and material use. This translates to better protection for products and potential reductions in transportation costs and environmental impact.

Furthermore, these minute technologies enable the development of smart packaging that can indicate the condition of the product. For instance, incorporating oxygen-sensitive nanoparticles that change color in the presence of oxygen can give a clear visual signal about the product's freshness.

In concluding, nanotechnology is a game-changing force in the realm of packaging. By improving preservation, strength, and intelligent monitoring capabilities, it is helping to craft the next generation of packaging solutions that are more effective, safe, and sustainable.

The Impact of IoT on Packaging Industry Trends

The Internet of Things (IoT) has introduced a new dimension to packaging technology by making packages more interactive and intelligent. With the integration of IoT, packaging is no longer a static entity but a dynamic part of the product experience and supply chain management.

Connected packaging equipped with IoT sensors and devices can provide real-time tracking and monitoring of products throughout the distribution process. Companies can now access data on location, temperature, humidity, and movement, enabling a more controlled and secure logistics operation.

IoT also facilitates predictive maintenance for packaging machinery. Sensors can detect potential issues before they cause downtime, allowing for proactive maintenance, improving productivity, and extending the life span of equipment.

On the consumer side, smart packaging linked with IoT can offer increased engagement and a wealth of information. For example, a consumer might scan a product's package with their smartphone to receive detailed product provenance, usage tips, or connect to a brand's customer service.

Packaging that communicates with other smart home devices, potentially adjusting to consumer usage patterns or preferences, is on the horizon. This kind of interoperability can further personalize the consumer experience and create seamless integration with the increasingly connected lifestyle of modern consumers.

In sum, the impact of IoT on the packaging industry points to a future where packaging is an integral part of a connected ecosystem. This convergence facilitates enhanced transparency, efficiency, and engagement, signaling a significant shift in industry trends towards smarter, more responsive packaging solutions.

Future Outlook: What to Expect in Packaging Innovations

The trajectory of packaging technology points toward a future marked by further personalization, sustainability, and interconnectivity. The possibilities for innovation within the industry are vast as new technologies continue to emerge and mature.

Advancements in material science are expected to yield even more sophisticated biodegradable and compostable packaging solutions. Research is focusing on combining the strength and flexibility of traditional materials with the environmental benefits of bio-based alternatives. The development of such materials may soon provide the same performance as conventional plastics with the added advantage of being fully compostable in a variety of environments.

Personalization and customization will likely reach new heights with the advent of AI-driven design tools. These tools will harness big data to predict consumer trends and preferences, allowing for packaging solutions that are not only tailored to the individual but also adaptive to changing market dynamics.

As for smart packaging, the future may bring about packages with built-in sensors that can do more than just track location or freshness. With advancements in nanotechnology, packages could monitor and maintain the optimal environment for the product inside, adjusting to changes in real-time.

Moreover, the role of automation and robotics will only expand, with the potential for fully automated, zero-waste packaging production lines. This evolution would represent a significant step forward in reducing the industry's carbon footprint and operational costs.

The integration of IoT will become more pervasive, leading to packaging that's not just a vessel for products, but a platform for data collection and interaction. The use of blockchains and distributed ledger technology could ensure the provenance and authenticity of products, providing a new level of security and trust for consumers.

In conclusion, the future of packaging innovation looks to be an exciting combination of green initiatives, technological sophistication, and enhanced customer engagement. The industry is set to evolve in ways that provide value not just for businesses, but for consumers and the environment alike.

Conclusion: Embracing the New Wave of Packaging Technology

As we survey the landscape of packaging technology, it's clear that we stand on the brink of a transformative era. Innovation is not just incrementally improving packaging; it's redefining what packaging is and what it can do.

The integration of advanced materials, intelligent design, and smart systems is creating packaging solutions that are at once more responsive to consumer needs and more respectful of environmental limits. With each leap forward—be it through the application of nanotechnology, the expansion of IoT, or the refinement of printing techniques—the packaging sector is not only meeting the challenges of today but is also anticipating the demands of tomorrow.

For businesses, the imperative is to harness these innovations to drive growth and differentiation in a competitive marketplace. Equipping packaging lines with the latest automation, robotics, and smart technologies can yield significant advantages in terms of efficiency, cost, and sustainability.

Consumers, on their part, can look forward to packaging that offers greater engagement, enhanced safety, and aligns with a conscientious lifestyle. The packaging of the future promises not only to protect and present products but to also communicate, inform, and interact in ways that add real value.

Embracing this new wave of packaging technology means investing in a future where packaging is no longer a mere afterthought, but a pivotal player in product experience and environmental stewardship. As we continue to innovate and adopt these technological advancements, we contribute to a future that's efficient, sustainable, and exciting—a future where packaging transcends its traditional role and becomes a key element in the smart, interconnected world we are building.

Top 5 FAQ on Emerging Trends in Packaging

What are bioplastics and how are they impacting packaging technology?

Bioplastics are materials produced from renewable biological resources such as cornstarch and sugarcane. They offer an environmentally-friendly alternative to traditional plastics by providing more efficient biodegradability, reducing plastic pollution, and conserving fossil resources.

How is nanotechnology being utilized in packaging?

Nanotechnology is being used to enhance packaging by integrating nanoparticles that improve barrier properties against moisture and gases, provide antimicrobial features to ensure food safety, and reinforce the material's strength and durability without increasing weight.

What are the benefits of smart packaging?

Smart packaging introduces interactive and intelligent features, such as QR codes, NFC tags, temperature-sensitive labels, and embedded sensors. These innovative additions enhance consumer engagement, offer real-time data insights, ensure product integrity, and streamline supply chain management.

What role does sustainability play in modern packaging technologies?

Sustainability is a core consideration in modern packaging, leading to the development of compostable materials, lightweighting to reduce resources, and closed-loop recycling systems. These advances aim to minimize environmental impact and align with consumer expectations for eco-friendly practices.

How is automation transforming the packaging industry?

Automation and robotics are transforming the packaging industry by increasing efficiency, enhancing precision, and reducing labor costs. The use of robotic systems, collaborative robots (cobots), and IoT-enabled machinery helps to optimize the packaging process and supports sustainable operations.