Introduction to the World of Packaging Factories

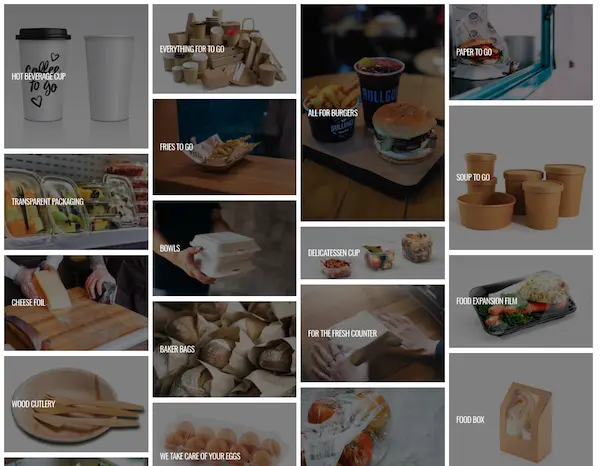

Imagine a world where every product you use has been encased, protected, and presented in a way that is both practical and appealing. This is the realm of packaging factories, the unsung heroes in the journey of a product. A packaging factory isn't just about boxes and wraps; it's an intricate dance of design, innovation, and engineering. As a consumer, you may only see the final product, but there's a wealth of activity and creativity that occurs behind the scenes. In this introduction, we'll peel back the curtain on the bustling world of packaging factories, showcasing the sophisticated processes that bring to life the packaging which plays a crucial role in our everyday experience with products.

What Happens Inside a Packaging Factory

Step through the doors of a packaging factory, and you'll enter a world where each phase of production is carefully choreographed. It begins with the conceptualization stage where experts design packaging that is not only functional but also aesthetically pleasing. Materials are then selected based on durability, cost-effectiveness, and environmental impact. Following this, machinery buzzes to life in the manufacturing process, transforming flat sheets of material into three-dimensional shapes through a series of cuts, folds, and joins.

With our network with packaging suppliers along with a huge international network, we provide customizable logistic packaging services as per the needs and requirements of our clients, in order to maintain continuous product development and greatly reduce the spending for packaging solutions.

Attention to detail is critical, as packaging must comply with regulations and client specifications. Advanced machines perform printing and labeling, adding branding elements and product information. In the assembly area, components are sometimes hand-assembled with precision, while other times, automated systems bring parts together with speed and consistency. Inspection stations are vital checkpoints where quality is scrutinized before the packaging is approved for shipment. The complexities inside a packaging factory are fascinating, and each step is essential to deliver packaging that protects and elevates the product within.

Pros and Cons of a Packaging Factory Tour

| Pros | Cons |

|---|---|

| Educational insight into packaging processes | Possible exposure to industrial hazards |

| Understanding of machinery and labor involved | May require strict safety protocols for visitors |

| Appreciation of the complexity behind product packaging | Could disrupt factory workflow during the visit |

| Opportunity to meet the workforce and learn about factory roles | Confidentiality issues with product designs |

| Exciting firsthand experience of a working environment | Time-consuming for factory staff to organize and conduct tours |

The Journey of a Product: From Design to Delivery

The lifecycle of a product's packaging is a tale of transformation. It starts with the spark of creativity in the design phase, where ideas and aesthetics converge to map out the packaging's form and function. Specialists consider factors such as protection, ease of transport, and how the packaging will display on shelves to captivate the end-user's attention.

Once the design is finalized, the prototyping stage ensues, where the theoretical becomes tangible. Sample packs are created to test and refine the design, ensuring it meets all practical requirements. The approved prototype then sets the standard for the mass production phase. This is where precision machinery takes the helm, replicating the prototype with exactness across thousands or even millions of units.

The filling and sealing operations signify the near completion of the journey as products are securely encased within their new protective homes. Finally, the packaged goods enter the distribution phase, where logistical planning sees packages being dispatched and transported to various destinations, ultimately arriving in the hands of consumers. Each phase in the packaging journey is a step towards delivering a product ready to make its mark in the market.

Cutting-Edge Technology in Modern Packaging Production

In the heart of modern packaging factories, cutting-edge technology propels the industry forward. Automation and robotics have become the backbone of efficient production lines, allowing for higher throughput with consistent quality. Advanced robotic arms and automated guided vehicles (AGVs) seamlessly move materials and products, optimizing workflow and minimizing the need for manual handling.

Digital printing technology has revolutionized how packaging is adorned with graphics and text. High-resolution printers offer unparalleled color accuracy and customization, making it possible to produce small runs of personalized packages or adjust designs on-the-fly with minimal waste. Additionally, 3D printing technologies are increasingly being integrated, providing the ability to quickly fabricate complex prototypes or mold designs for bespoke packaging solutions.

Furthermore, the integration of Internet of Things (IoT) devices within packaging operations enables real-time monitoring and data analysis. This IoT ecosystem within factories paves the way for predictive maintenance of machinery, efficiency optimizations, and even comprehensive tracking of the product’s packaging lifecycle. Through such technological advancements, packaging factories are setting new standards for innovation, agility, and sustainability in the manufacturing sector.

Sustainability Practices in Packaging Manufacturing

Sustainability has become a cornerstone in packaging manufacturing, as eco-friendly practices are increasingly demanded by consumers and imposed by regulations. Modern packaging factories are adopting a plethora of green initiatives to minimize environmental impact. One such initiative includes using recyclable materials and developing packaging designs that require less material without compromising the integrity of the product.

Moreover, the use of biodegradable alternatives is on the rise, with materials such as plant-based plastics and mushroom mycelium being explored for their low environmental footprint. Energy consumption is another critical focus area, with factories investing in energy-efficient machinery, solar panels, and comprehensive waste management systems that aim to recycle factory waste into usable materials.

A push for a circular economy is evident as packaging manufacturers engage in 'closed-loop' recycling systems, ensuring that used packaging is recollected, reprocessed, and remade into new packaging, thereby reducing the reliance on virgin materials. These sustainability practices in packaging manufacturing not only further environmental stewardship but also align with the growing global commitment to a more sustainable future.

Quality Control: Ensuring Excellence in Packaging

Within the bustling environment of a packaging factory, quality control is a pivotal chapter in the narrative of manufacturing excellence. Rigorous quality assurance protocols are embedded throughout the production process to guarantee that each piece of packaging meets stringent standards for durability, design accuracy, and functionality. Inspectors employ a mix of manual examinations and automated systems to check for defects, inconsistencies, and compliance with specifications.

State-of-the-art inspection equipment such as high-speed cameras and precision sensors are key players in the quality control arsenal. These tools enable rapid, non-destructive testing to identify imperfections that might be invisible to the naked eye, thus ensuring that only faultless packaging leaves the factory floor. In addition to physical inspections, packaging batches are often subject to stress tests meant to simulate conditions they will face during shipping and handling, ensuring their resilience and protective capabilities remain uncompromised.

The commitment to quality control in a packaging factory extends beyond the tangible product. It encompasses a commitment to maintaining a systematic approach to continuous improvement and adherence to compliance requirements. This maintains consumer trust and solidifies the reputation of the brand in a competitive marketplace.

The Role of Human Expertise in Packaging Factories

Despite the technological leaps in the industry, the role of human expertise in packaging factories remains irreplaceable. Human insight and experience are crucial in overseeing the nuances of packaging production. Skilled professionals in the field bring a level of problem-solving and innovation that machines alone cannot replicate. They are responsible for the strategic planning and fine-tuning of machinery to handle complex tasks, ensuring that the integration of automation enhances rather than impedes the production line.

From designers crafting the initial packaging concepts to engineers optimizing production processes, the human touch is evident. Technicians perform essential maintenance and troubleshooting to keep the high-tech machinery running at peak efficiency. Quality assurance teams rely on their keen eyes and judgement to uphold the highest standards of production quality.

In the dynamic world of packaging, the adaptability and creative capabilities of humans drive the evolution of packaging solutions, ensuring that the industry not only meets current demands but also anticipates future trends and needs. The blend of human expertise with advanced technology creates a synergy that is the lifeblood of a thriving packaging factory.

Innovations Shaping the Future of Packaging Factories

The future of packaging factories is being carved out by continuous innovations, driving the industry towards newer, smarter, and more eco-friendly horizons. Emerging technologies such as Augmented Reality (AR) are starting to make headway, allowing for real-time visualizations of packaging designs and facilitating rapid prototyping. This reduces the need for physical samples and accelerates the development process from concept to final product.

Additionally, breakthroughs in smart packaging are introducing interactive experiences for consumers. These packages are embedded with technologies like QR codes and NFC tags that, when scanned with smartphones, can provide a wealth of information—from the product's origin to how to recycle the packaging correctly.

The application of machine learning algorithms offers predictive insights that can optimize supply chains, reduce waste, and improve production efficiency. As machine learning continues to evolve, we will likely see more anticipatory packaging designs, capable of dynamically adjusting to changing consumer behaviors and market conditions.

Lastly, advancements in material science are leading to the creation of new substrates with superior properties, ranging from enhanced barrier protection to increased recyclability. The ongoing push for sustainable solutions is ever-present, with the development of packaging that not only serves its practical purposes but also contributes positively to the environment.

Challenges and Solutions in Packaging Production

As with any industry, packaging production faces its set of challenges, ranging from operational efficiencies to environmental responsibilities. One significant challenge is the balance between meeting high production demands and maintaining quality. This is often addressed by continuous process optimization and investing in employee training to improve skill sets that enhance productivity.

Another pressing issue is the impact of packaging on the environment. Factories are tackling this by sourcing sustainable materials and incorporating upcycling methods to reduce waste. Forward-thinking companies are also exploring Life Cycle Assessments (LCAs) to better understand their products' environmental impacts and make data-driven improvements.

On the logistical side, the complexities of supply chain management pose a challenge, especially in a global market. Adopting Just-In-Time (JIT) production and improving inventory management with intelligent software can mitigate risks associated with overproduction and storage costs.

Lastly, keeping up with changing regulations and consumer preferences requires agility and a proactive approach. This involves regular monitoring of market trends and regulatory changes, ensuring that packaging production remains compliant and relevant.

Conclusion: The Impact of Packaging Factories on Our Daily Lives

The influence of packaging factories on our daily lives is both profound and pervasive, often going unnoticed as we interact with an array of packaged products. They are vital in protecting goods, providing information, and promoting brands, thereby playing a critical role in the global economy. As we move forward, these factories will continue to adapt, evolve, and innovate, meeting the challenges of sustainability and efficiency head-on.

The strides made in technology and sustainable practices within these factories have a ripple effect, influencing consumer behavior and the health of our planet. By embracing innovations and maintaining a commitment to quality and environmental stewardship, packaging factories are not just manufacturing containers, but are shaping the very experience of consumerism and product engagement.

In conclusion, the ongoing efforts in packaging factories around the globe reflect a commitment to excellence and responsibility that resonates with each of us. As we become more conscientious about the products we use and the packaging that accompanies them, we can appreciate the intricate processes and dedicated workforce that make it all possible. The future of packaging is bright, informed by past achievements and inspired by the limitless possibilities that innovation and sustainability bring.

FAQ: Uncovering the Essentials of Packaging Factories

What is the primary function of a packaging factory?

The primary function of a packaging factory is to design, produce, and supply packaging materials for various products. This includes conceptualizing the packaging design, selecting materials, manufacturing, and ensuring quality control to protect and enhance the products within.

How does technology influence the operations of a packaging factory?

Technology plays a critical role in modern packaging factories by improving efficiency, accuracy, and sustainability. Automation and robotics expedite the manufacturing process, digital printing offers high-quality graphics, and IoT devices enable real-time monitoring and optimization of production.

What sustainability practices are implemented in packaging factories?

Packaging factories implement various sustainability practices, such as using recyclable and biodegradable materials, reducing waste through efficient design and upcycling, utilizing energy-efficient machinery, and participating in closed-loop recycling systems to support the circular economy.

Why is human expertise important in packaging factories?

Human expertise is vital in packaging factories because it brings creativity, innovation, and problem-solving capabilities that machines cannot replicate. Skilled professionals are needed for design, strategic planning, fine-tuning machinery, maintenance, and quality assurance to ensure the highest production standards.

What are the challenges faced by packaging factories today?

Packaging factories face challenges such as balancing high production demands with quality, reducing environmental impact, managing complex supply chains, and staying compliant with changing regulations. They address these challenges through continuous process optimization, adoption of sustainable practices, and agile response to market dynamics.