Understanding the Basics of Packaging and Packaging Waste Regulation (PPWR)

Packaging and Packaging Waste Regulation, commonly referred to as PPWR, is a critical framework set to address the environmental impact of packaging materials and the waste they become after use. Implementing this regulation is paramount as it lays down specific requirements that must be adhered to by those involved in the packaging lifecycle - from creation to disposal. It is designed to promote the circular economy by boosting the reuse and recycling of packaging materials.

The essence of PPWR is to ensure that packaging placed on the market does not harm the environment. This involves enforcing design standards that encourage reduction in material use and enhance recyclability. PPWR mandates that by 2030, all packaging should be either reusable or recyclable in an economically feasible way. It's not only about minimizing the waste but also about optimizing resources and processes to maintain material value over time.

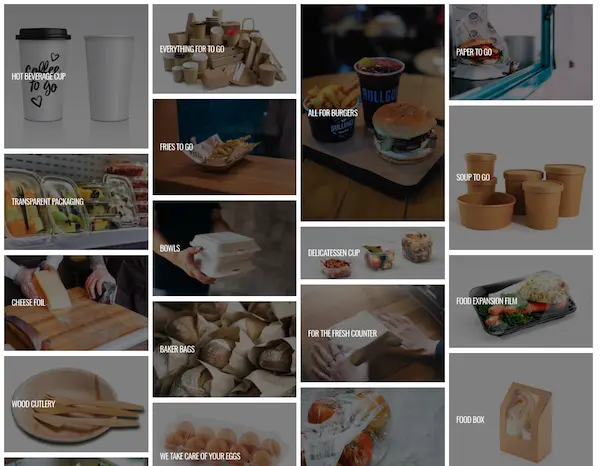

With our network with packaging suppliers along with a huge international network, we provide customizable logistic packaging services as per the needs and requirements of our clients, in order to maintain continuous product development and greatly reduce the spending for packaging solutions.

Understanding PPWR is essential for all stakeholders in the packaging industry, particularly manufacturers, distributors, retailers, and consumers. Each group has a role to play in achieving compliance with the regulation and contributing to a sustainable environment. Manufacturers may need to adjust their design and production processes, while consumers are encouraged to participate in recycling programs. Retailers, on their part, must ensure that the products they sell conform to PPWR standards.

As a consequence of PPWR regulations, businesses may be required to contribute to the cost of recycling the materials they place on the market. This concept, known as Extended Producer Responsibility (EPR), is foundational to PPWR. It incentivizes manufacturers to produce packaging that is easier and more cost-effective to recycle. Therefore, navigating the intricacies of PPWR is not just about complying with the law but also about embodying a commitment to environmental stewardship.

The Importance of PPWR for Businesses and Consumers

The Packaging and Packaging Waste Regulation (PPWR) holds significant importance for both businesses and consumers, predominantly in fostering a sustainable economy and reducing the ecological footprint. For businesses, adhering to PPWR is not just a regulatory mandate but a move towards operational efficiency and fostering brand loyalty. Companies that align their operations with these regulations demonstrate responsibility and commitment to environmental sustainability, which can enhance their reputation and appeal to a growing demographic of eco-conscious consumers.

On the consumer side, PPWR influences the market by ensuring that the products they purchase are contained in packaging that is less harmful to the environment. This regulation empowers consumers by providing them with greener choices. As informed individuals play a more active role in reducing waste, PPWR initiatives can significantly drive consumer behavior towards more eco-friendly purchasing patterns.

Furthermore, PPWR also stimulates innovation as businesses are pushed to find new ways to design and produce sustainable packaging. This can lead to advancements in materials science and packaging technologies that not only benefit the environment but also create new market opportunities. Through these innovative measures, the regulation not only guides but also supports the industry in its transition towards a greener future.

In essence, the synergy between businesses improving their packaging strategies and consumers making conscious choices is what can propel the objectives of PPWR. By understanding and acting in accordance with the PPWR, both parties contribute to a larger goal of environmental conservation and a healthier planet for future generations.

Pros and Cons of Packaging and Packaging Waste Regulation

| Pros of PPWR | Cons of PPWR |

|---|---|

| Encourages the use of eco-friendly materials | Can increase costs for businesses |

| Reduces environmental pollution | May lead to complex compliance processes |

| Promotes recycling and waste management | Could cause increased product prices for consumers |

| Incentivizes innovation in packaging design | May be difficult for small companies to implement |

| Helps in conservation of natural resources | Potential for regulatory discrepancies between regions |

Key Objectives of the Packaging and Packaging Waste Directive

The Packaging and Packaging Waste Directive (PPWD) is built on several key objectives that serve as its guiding principles. These objectives aim to create a cohesive approach across member states to manage packaging and packaging waste more effectively while minimizing the environmental impact. The Directive seeks to harmonize national measures, ensuring that the movement of goods on the internal market is not impeded, yet environmental protection requirements are maintained and optimized.

One of the principal goals of the PPWD is to prevent the production of packaging waste by encouraging the development and adoption of packaging solutions that maintain the necessary level of safety and hygiene for the packaged goods with the least possible material use. Moreover, the Directive promotes the reuse of packaging, thereby extending its lifecycle and reducing the need for new materials.

Recycling and other forms of recovering packaging waste are also central to the objectives of the Directive. It places a strong emphasis on increasing recycling rates and the use of recycled material in new packaging. This not only diverts waste from landfills and reduces environmental pollution but also conserves natural resources by reintegrating materials back into the production cycle.

Finally, the PPWD sets forth measures to ensure that no packaging waste is disposed of in a manner that may harm the environment. This includes restrictions on the use of certain substances in packaging materials and advocating for effective waste management practices. Through these objectives, the PPWD aims to lead Europe towards a circular economy where packaging sustainability plays a pivotal role.

How PPWR Affects Packaging Design and Materials

The Packaging and Packaging Waste Regulation (PPWR) has a profound influence on the design and choice of materials used for packaging. Manufacturers are now required to thoughtfully consider the entire lifecycle of their packaging options, from creation to potential reuse and recycling. This regulatory environment accelerates the move toward eco-design principles, where the environmental impact of packaging is minimized without compromising its quality and functionality.

Packaging design, under the guidance of PPWR, is shifting to reduce complexity and increase purity of materials. This leads to more streamlined recycling processes as the need for separation and specialized handling is diminished. Simplification of packaging materials means that recycling becomes more straightforward and efficient, with a greater percentage of material being recoverable at the end of its life.

Material selection is another facet profoundly affected by PPWR. Designers and manufacturers are encouraged to choose materials that have a lower environmental footprint and are more easily recyclable. There is a growing emphasis on using renewable, biodegradable, or compostable materials as alternatives to traditional plastics. These materials can provide similar levels of functionality while being more aligned with circular economy goals.

In response to PPWR, companies are not only reconsidering the materials they use, but they are also innovating in the fields of material science and packaging technology. This leads to new, more sustainable packaging options entering the market, which not only meet regulatory standards but also enhance brand image and consumer appeal.

Navigating Compliance: Strategies for Adhering to PPWR

Navigating the regulatory landscape of the Packaging and Packaging Waste Regulation (PPWR) calls for strategic planning and execution. Companies must implement comprehensive strategies to meet and maintain compliance with the evolving stipulations of PPWR. A key aspect involves conducting detailed audits of existing packaging, identifying areas that fall short of compliance, and making the necessary alterations.

Developing an in-depth understanding of the legislation is essential. Businesses should stay informed about the latest developments in PPWR requirements and prepare for future regulations. This can involve working with legal and environmental consultants to interpret the directives and to understand their implications for the company's operations.

In addition to internal reviews and learning, engaging in collaboration with supply chain partners is crucial. For many businesses, achieving compliance means working closely with material suppliers, packaging designers, and waste management services that are also aligned with PPWR. Joint efforts can lead to shared solutions that benefit all parties involved.

Investment in sustainable innovation is another strategic approach under PPWR. Businesses may decide to invest in research and development to create new materials or to redesign products to reduce the environmental impact of their packaging. Accessing support, such as government grants or partnerships with academic institutions, can be ways to mitigate the costs associated with these innovations.

Lastly, adopting transparent reporting mechanisms ensures that compliance achievements are properly documented and communicated. This not only serves regulatory purposes but can also enhance the brand's image by showcasing commitment to sustainability and regulatory adherence to customers and other stakeholders.

The Role of Extended Producer Responsibility in PPWR

Extended Producer Responsibility (EPR) is a cornerstone policy mechanism within the PPWR framework, designed to extend the accountability of producers for the environmental impacts of their products throughout the product lifecycle, including end-of-life disposal. EPR is intended to motivate producers to consider the downstream consequences of their packaging choices and to take steps to mitigate negative environmental effects.

This responsibility incentivizes producers to redesign packaging with sustainability in mind, leading to the use of materials that are easier to recycle, repair, or repurpose. It also encourages the development of take-back schemes and recycling initiatives that ensure the proper disposal and treatment of packaging waste, thus closing the loop on product life cycles.

The financial aspect of EPR compels manufacturers to contribute to the costs associated with the collection, treatment, and recovery of packaging waste. These financial contributions are proportionate to the amount of packaging each producer introduces to the market, ensuring that the polluter pays principle is applied, where the costs of managing waste are borne by those who generate it.

Furthermore, EPR serves as a critical driver for innovation, with companies seeking cost-effective ways to reduce the environmental footprint of their packaging. This often results in the exploration of circular economy solutions that can be integrated into the business model, ultimately leading to more sustainable production and consumption patterns.

Meeting the 2030 Goals for Reusable and Recyclable Packaging

Meeting the ambitious 2030 goals for reusable and recyclable packaging is an integral component in the drive towards a more sustainable future. These targets are pivotal milestones in operationalizing the PPWR vision, ensuring that all packaging circulating within the market can embark on a continued lifecycle post-consumption.

Achieving these goals requires a multi-faceted approach, starting with the promotion of design for reuse. Packaging should not only be sturdy enough to withstand multiple use cycles but also designed in a way that encourages users to return them for a new cycle of use. This could be further supported by systems which provide incentives for the return of packaging.

For packaging that is not reused, ensuring that it is fully recyclable remains essential. To this end, development and use of mono-materials that are easier to process in recycling facilities contribute significantly to meeting recycling goals. Reducing the mix of materials in a single packaging type simplifies the recycling process, improving the quality and quantity of recovered materials.

Another key aspect is the adoption and enhancement of innovative recycling technologies. Breakthroughs in chemical recycling and improved sorting technologies can unlock recycling capabilities for materials that were previously deemed non-recyclable.

Industry-wide collaboration and strong governmental support are also paramount. Stakeholders across the value chain - from manufacturers to recyclers - need to align their efforts, backed by policies and initiatives that provide the necessary infrastructure for collecting and processing packaging waste.

Ultimately, the fulfillment of the 2030 goals will be measured by the tangible shifts in both the design of packaging and an increase in the rates of reuse and recycling, supported by a regulatory environment that promotes continual improvement toward these ends.

The Impact of PPWR on Packaging Waste Management

The Packaging and Packaging Waste Regulation (PPWR) exerts a transformative impact on the management of packaging waste. By setting forth robust directives, PPWR reshapes how packaging waste is approached, prioritizing reduction, reuse, and recycling. As these regulatory guidelines are implemented, waste management practices undergo a necessary evolution, aligning with a broader environmental consciousness.

Integral to effective packaging waste management is the establishment of a streamlined collection system. PPWR encourages member states to adopt consistent and efficient waste collection schemes to improve the segregation of recyclable materials from general waste streams, thereby enhancing the quality of materials available for recycling.

PPWR also drives advancements in recycling facilities and techniques. The need to handle increasingly diverse types of packaging waste effectively has spurred investment in state-of-the-art sorting and processing plants capable of accommodating the stringent recycling targets mandated by the regulation.

Emphasis on infrastructure development is accompanied by the promotion of public awareness and education programs. PPWR recognizes the importance of consumer participation in achieving waste management objectives and encourages initiatives that inform the public about their role in the recycling process and the importance of proper disposal practices.

Moreover, PPWR steers the shift towards a closed-loop economy. By incentivizing the incorporation of recycled materials into new products, the regulation not only reduces waste but supports the creation of a market where materials are reused, bringing us closer to a zero-waste future.

Innovations and Best Practices in Sustainable Packaging

In the pursuit of sustainability, innovations and best practices in packaging are rapidly evolving, driven by global initiatives such as the PPWR. Stakeholders in the industry are continually exploring new ways to not only comply with regulations but also to set new benchmarks in eco-friendly packaging solutions.

One of the emerging trends is the use of biodegradable and compostable materials in packaging. These materials break down naturally and reduce the accumulation of waste in the environment. More companies are leveraging such materials to create packaging that can be processed organically at the end of its life cycle.

Another key innovation is the advance in smart packaging technologies. These technologies enable better tracking and management of products throughout the supply chain. Embedded features like QR codes or RFID tags encourage proper sorting and recycling, and also provide consumers with information regarding the sustainability of the packaging.

Adopting modular packaging designs is also becoming a best practice within the industry. Such designs allow for parts of the packaging to be interchanged or replaced, reducing the need for a completely new package and thereby minimizing waste.

Furthermore, there is a significant move towards refillable and reusable packaging systems. These systems offer consumers a way to replenish their products without generating additional packaging waste, aligning consumer convenience with environmental responsibility.

These innovations, among others, represent a collective step forward in packaging sustainability. They not only comply with regulatory measures like PPWR but also signify an industry-wide commitment to reducing the ecological footprint of packaging.

The Future of Packaging: Trends Shaped by PPWR

The trajectory of packaging is being significantly redefined by the principles and mandates of the PPWR. Anticipating the future trends in this domain, it's evident that sustainability will continue to be a major driving force, influencing every aspect from material selection to manufacturing processes and consumer interaction with packaging.

A trend set to gain momentum is the rise of digital printing and labeling techniques that allow for greater customization and flexibility in packaging. These methods contribute to reducing waste by enabling short-run production cycles and decreasing excess inventory that often leads to disposal.

Expect to see an increase in the deployment of alternative materials that challenge the traditional reliance on plastics. Innovations in plant-based plastics, organic fabrics, and other sustainable materials will likely keep expanding as viable packaging options, reducing dependency on fossil fuel-derived products.

The concepts of minimalism and simplicity in packaging design are anticipated to flourish. As consumers and regulators alike demand less waste, the adoption of simpler, more material-efficient packaging designs will become a standard practice for forward-thinking companies.

Also, as PPWR regulations put pressure on reducing waste, there will likely be a surge in packaging-as-a-service models. These models envision packaging as a reusable asset rather than a single-use item, enabling a service-based approach to its utilization and recovery.

In conclusion, under the influence of the PPWR, the packaging sector is moving towards a future where innovation, sustainability, and circular economy principles converge to create eco-efficient packaging solutions that protect the environment and cater to the evolving needs of society.

Conclusion: Embracing Change and Advancing Sustainability with PPWR

In conclusion, the Packaging and Packaging Waste Regulation (PPWR) represents a driving force for environmental stewardship and innovation within the packaging industry. Its comprehensive approach to reducing the ecological footprint of packaging has ushered in numerous changes that businesses and consumers are adapting to. By shifting the paradigm to prioritize sustainability, the regulation ensures that packaging is designed, used, and disposed of with a conscious effort to minimize its impact on the planet.

The implications of PPWR extend beyond compliance; they are shaping a new culture in packaging – one where the lifecycle of packaging materials is carefully considered, and where the value of resources is preserved through circular economy practices. Embracing this change presents opportunities for businesses to demonstrate leadership in sustainability and to gain a competitive edge in a marketplace that increasingly values environmental responsibility.

As we look towards a more sustainable future, the principles of PPWR guide us in establishing best practices and stimulate ingenuity across the industry. It is a collective journey, and each stakeholder plays a pivotal role in advancing towards the shared vision of a world where packaging exists in harmony with the environment. The PPWR is more than a set of regulations; it is a catalyst for positive change, compelling all of us to consider the legacy we leave for future generations through the choices we make today.

Comprehensive Guide to Packaging Waste Regulation

What is the Packaging and Packaging Waste Regulation (PPWR)?

PPWR is legislation that sets forth requirements for the reduction and management of packaging and packaging waste. It aims to minimize the impact of packaging on the environment through design standards, recycling mandates, and Extended Producer Responsibility (EPR) systems.

How does PPWR affect packaging design and materials?

PPWR influences packaging design by encouraging manufacturers to adopt eco-design principles that reduce material complexity and enhance recyclability. Material selection focuses on lower environmental footprint and increased potential for reuse and recycling.

What role does Extended Producer Responsibility (EPR) play in PPWR?

EPR is a policy within PPWR whereby producers are held accountable for the environmental impacts of their packaging throughout the product lifecycle. This motivates producers to design sustainable packaging and fund recycling efforts.

What are the 2030 goals for reusable and recyclable packaging?

The 2030 goals set by the PPWR mandate that all packaging must be reusable or recyclable in an economically viable way by 2030. This includes promoting reuse, designing for recycling, and investing in recycling technologies and infrastructure.

How can companies ensure compliance with PPWR?

Companies can ensure compliance by conducting audits, understanding the legislation, collaborating with supply chain partners, investing in sustainable innovations, and implementing transparent reporting mechanisms.