Understanding the Basics of Packaging Materials

Before delving into the specific types of packaging materials available, it's crucial to grasp the fundamental purpose and importance of packaging in the product lifecycle. Packaging serves not just as a means to protect and preserve products during transportation and storage, but it also plays a significant role in marketing and branding efforts. As a consumer's first point of physical contact with a product, packaging can influence purchasing decisions and brand perception.

At its core, packaging must achieve several objectives: contain the product, protect it from damage, preserve its condition, provide necessary information, and facilitate transportation and handling. To meet these goals, manufacturers select materials based on criteria such as durability, weight, cost, sustainability, and compliance with industry standards and regulations.

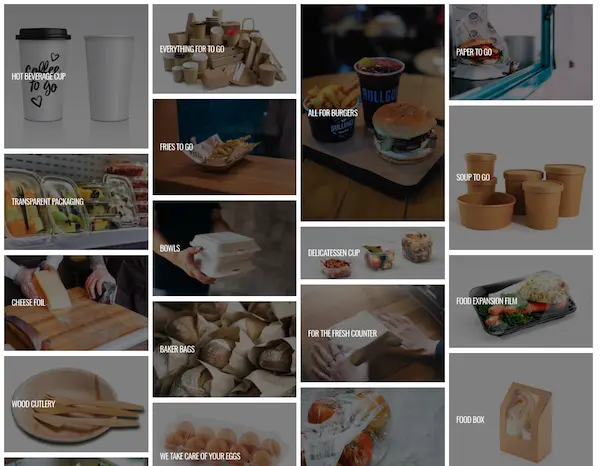

With our network with packaging suppliers along with a huge international network, we provide customizable logistic packaging services as per the needs and requirements of our clients, in order to maintain continuous product development and greatly reduce the spending for packaging solutions.

An understanding of the common types of packaging materials also encompasses recognizing their environmental impact. This knowledge guides businesses and consumers alike towards more sustainable choices. With an ever-growing emphasis on sustainability, the packaging industry continues to evolve, with innovation focused on reducing waste and improving recyclability.

Choosing the right type of packaging material not only ensures product safety and adds value to a brand but also reflects a company's values and commitment to environmental responsibility.

Whether choosing materials for large-scale industrial needs or small, bespoke shipments, a solid understanding of the various packaging materials available is indispensable. The following sections will elaborate on each type, their unique benefits, and their most suitable applications.

Exploring the World of Plastic Packaging Options

Plastic packaging stands as one of the most versatile and widely used materials in the world of packaging. Its prevalence comes from its ability to take on numerous forms and characteristics – from rigid containers to flexible films. Plastics such as PET (Polyethylene Terephthalate), HDPE (High-Density Polyethylene), and PVC (Polyvinyl Chloride) are commonplace in packaging applications due to their strength, lightweight nature, and clarity.

When exploring plastic packaging options, one will encounter both thermoplastics and thermosets. Thermoplastics, like the commonly used polystyrene, are moldable upon heating and can be remolded multiple times. Thermosets, on the other hand, maintain their shape once hardened and boast high resistance to heat, making them suitable for items that undergo thermal exposure.

- Flexible Plastic Packaging: Often used for bags, wraps, and pouches; characterized by its malleability.

- Rigid Plastic Packaging: Utilized for items requiring sturdier protection like bottles, trays, and tubs.

- Foamed Plastic Packaging: Provides cushioning and insulation, suitable for protective packaging.

- Composite Plastic Packaging: A combination of various materials to leverage the benefits of each.

The selection of plastic packaging also takes into consideration its capacity for recycling. Certain plastics are more readily recyclable than others, and the numbering system seen on plastic products (from #1 to #7) aids in identifying their recyclability.

Businesses often opt for plastic packaging when looking for cost-efficiency, design flexibility, and product visibility. However, with plastic waste being a critical environmental issue, the industry is leaning towards options that balance functionality with sustainability, leading to the rise of bioplastics and more recycling-friendly plastic materials.

While plastic packaging continues to dominate many sectors, the push for eco-conscious solutions is shaping new trends and innovations in this area.

Comparative Analysis of Packaging Material Choices

| Packaging Material | Pros | Cons |

|---|---|---|

| Cardboard |

|

|

| Plastic |

|

|

| Glass |

|

|

| Metal |

|

|

| Biodegradable Plastics |

|

|

The Role of Glass in Product Packaging

Glass, prized for its transparency and impermeability, provides a high level of protection against contaminants and is not reactive with most products. Due to these attributes, glass is a preferred choice for packaging a wide range of goods, especially food and beverages, cosmetics, and pharmaceuticals.

One of the most significant advantages of glass is its reusability and recyclability. Glass can be recycled indefinitely without losing its purity or quality, which is why it remains a constant in an eco-conscious market. This material can also be sterilized and reused multiple times, furthering its appeal for sustainable packaging solutions.

Despite its advantages, glass packaging does have some limitations. Its weight and fragility can result in higher transportation costs and greater care needed during handling. Nevertheless, its benefits often outweigh these concerns, particularly when packaging premium products where quality and aesthetic appeal are paramount.

In the consumer market, glass conveys a message of quality and sophistication. It is often chosen for products that aim for a high-end appeal, as its clarity showcases the contents within, and its substantial feel enhances the user experience.

As trends continue to favor sustainable and recyclable materials, glass maintains its status as a key player in the packaging industry. Its enduring role is a testament to its functionality, safety, and alignment with environmental values.

Choosing glass for product packaging reflects a commitment to preserving purity, enhancing user experience, and promoting sustainability.

Metal Packaging: Durability and Sustainability

Metal packaging, known for its strength and protection, stands as a durable choice for a broad spectrum of products. Materials like aluminum and steel are extensively used in the creation of cans, containers, and caps. Metal's resistance to moisture, light, and air makes it ideal for the long-term preservation of food, beverages, and chemicals.

For products requiring a barrier from external elements, metal packaging offers an almost unmatched level of security. Its structural rigidity ensures goods are shielded from physical damage, an essential feature for items in transit or in harsh storage conditions.

Aluminum packaging is especially popular due to its lightweight nature and resistance to corrosion. Frequently used for drinks and aerosol sprays, it's also entirely recyclable, which resonates with eco-friendly practices. The recycling rate for aluminum is among the highest of all materials, further contributing to its environmental credentials.

Steel, used for heavier-duty containers, is valued for its ruggedness and has an impressive recycling story as well. Tinplate steel, often coated to prevent rusting, is a common choice for food cans and offers an extra layer of product safety.

When pondering the role of metals in the packaging landscape, their recyclability and long lifespan are at the forefront. These qualities endorse metals as sustainable materials that can help to reduce overall waste and resource consumption.

The inclusion of metal packaging in product design not only conveys durability but also demonstrates a brand's commitment to sustainability.

Paper and Cardboard Packaging: Eco-Friendly Choices

Paper and cardboard stand out in the packaging industry as the go-to options for those seeking environmentally conscious materials. These renewable resources are favored for their versatility and are commonly used to create boxes, cartons, bags, and wraps.

The wide utilization of paper and cardboard is partly due to their biodegradability and capacity for recycling. They break down naturally and can be turned into new products through a relatively energy-efficient recycling process. This aligns with global efforts to minimize environmental impact and supports the circular economy.

The customization possibilities with paper and cardboard are extensive. They offer a canvas for eye-catching designs and branding, which is invaluable for marketing and customer attraction. Additionally, innovations in paper technology have led to increased durability and functionality, including options for waterproofing and structural reinforcement.

While paper and cardboard packaging may not be suitable for all products, especially those requiring airtight or moisture-resistant solutions, they are excellent for items that do not demand stringent barrier properties. They provide ample protection for goods in transit, particularly when paired with cushioning materials like paper fill or corrugated inserts.

Companies tend to opt for paper and cardboard when they aim to project an image of sustainability and responsibility, while not compromising on protection and presentation. The ability to use recycled content in these packaging options further lessens the environmental load.

Paper and cardboard packaging solutions affirm a brand's dedication to ecological balance and showcase an understanding of the current consumer's preference for green alternatives.

Wooden Packaging Solutions: Natural and Sturdy

Wooden packaging, often revered for its authenticity and robustness, harks back to one of the oldest materials used in packaging. Wood is still very much prevalent today, particularly in the form of pallets, crates, barrels, and baskets. Its natural origin and aesthetic appeal make it a sought-after choice for brands that prioritize traditional and premium packaging experiences.

The durability of wood is a distinguishing characteristic, offering excellent protection for heavy or high-value items, especially during shipping. Wood's inherent strength makes it capable of supporting substantial weight, which is essential for bulk transportation.

Despite concerns over deforestation, responsibly sourced wood, such as that certified by the Forest Stewardship Council (FSC), provides a sustainable option that ensures environmental and socioeconomic benefits. When harvested and managed correctly, wood can be a sustainable resource due to its renewability and carbon-neutral status when responsibly disposed of or recycled.

Moreover, advances in wood treatment and processing have improved its resistance to weathering, pests, and decay, extending its usability and reducing waste. Wood can also be repurposed into various other products, further emphasizing its versatility and sustainability.

Opting for wooden packaging can denote a brand's commitment to blending performance with an ecological mindset, embodying values that many contemporary consumers resonate with.

Wooden packaging not only secures goods with its substantial structure but also speaks to a brand's eco-friendly ethos and quality craftsmanship.

Innovative Biodegradable and Eco-Friendly Packaging Materials

In the quest for sustainability, innovative biodegradable and eco-friendly packaging materials are rapidly gaining traction in the packaging industry. These materials are designed to decompose naturally and safely, often through composting, reducing the reliance on traditional waste disposal methods and minimizing environmental impact.

Examples of such innovative materials include plant-based plastics, which are derived from renewable resources such as corn starch, sugarcane, or potatoes. Unlike conventional plastics, these bio-based alternatives can break down and return to nature under the right conditions, offering a more sustainable lifecycle.

Additionally, the use of edible packaging solutions is emerging, where the packaging can be consumed along with the product, leaving no waste behind. Innovations also extend to biodegradable films and coatings that protect products while promising minimal environmental residue upon disposal.

Materials such as mushroom mycelium and seaweed extract have been developed into packaging forms, providing unique and effective alternatives to synthetic options. These materials are not only biodegradable but are often produced with less energy and fewer resources than conventional materials.

Brands that adopt these pioneering materials showcase their forward-thinking and environmental stewardship. As technology advances, these eco-friendly materials continue to improve in terms of durability and functionality, aligning with consumer and regulatory demands for greener packaging.

By integrating innovative biodegradable and eco-friendly packaging materials into their products, companies can significantly reduce their ecological footprint and meet consumer expectations for sustainability.

The Impact of COVID-19 on Packaging Material Trends

The COVID-19 pandemic has had a profound influence on packaging material trends, accelerating shifts towards safety, hygiene, and sustainability. The outbreak has heightened consumer awareness on health and sanitation, leading to an increased demand for packaging options that minimize the risk of contamination.

During the peak of the pandemic, the preference for single-use packaging saw a temporary spike as individuals and businesses sought to limit exposure to the virus. This surge highlighted the need for balance between protective packaging and environmental considerations.

As e-commerce experienced unprecedented growth due to lockdowns and social distancing measures, packaging materials that support online shopping and delivery services became more vital. This led to a pressing need for reliable and resilient packaging that can withstand the rigors of shipping and handling.

Yet, this increased consumption prompted concerns about packaging waste, thereby reinforcing the call for sustainable and recyclable packaging solutions. Subsequently, the industry has seen a greater emphasis on reducing material usage and enhancing the recyclability of packaging.

Furthermore, the pandemic has prompted a reevaluation of supply chain resilience, with companies diversifying their sourcing of packaging materials to mitigate against potential disruptions.

In reaction to the pandemic's impact, many packaging material manufacturers and brands are reassessing and adapting their strategies, leading to innovations that are expected to influence long-term packaging trends.

COVID-19's challenges have underscored the importance of agile, safe, and sustainable packaging solutions, which are likely to shape the industry for years to come.

Selecting the Right Packaging Material for Your Business

Selecting the ideal packaging material is a critical decision that can affect your product's market success, safety, and your company's sustainability initiatives. To make an informed choice, businesses must consider a variety of factors that align with their unique product needs and brand values.

Functionality should be the primary concern. The packaging must adequately protect the product during transportation and storage and possibly extend its shelf life. Understanding the physical and chemical properties of the product, such as weight, shape, fragility, and sensitivity to light or moisture, is essential in determining the most suitable packaging material.

Branding is another key component that influences packaging material choice. The package is an extension of your brand and an effective tool for engaging with customers. It is important to select materials that allow for high-quality printing and design to communicate the brand message effectively and make your product stand out on the shelf.

Cost-efficiency is always necessary to contemplate, as packaging expenses can represent a significant portion of the product cost. Balancing quality and affordability is a delicate process that can dictate profitability and price point.

Equally important is the consideration for environmental sustainability. With consumers and regulations increasingly favoring eco-friendly materials, selecting recyclable, biodegradable, or compostable packaging can be advantageous for both the environment and brand reputation.

Lastly, compliance with industry regulations ensures that the packaging adheres to safety and health standards, which is particularly relevant for food, beverage, and pharmaceutical products.

Choosing the right packaging material requires a multifaceted approach that not only meets functional requirements but also embodies the brand's ethos, prioritizes cost-effectiveness, and respects environmental responsibilities.

Packaging Materials on Amazon Business: A World of Choices

Amazon Business provides a vast selection of packaging materials, catering to the diverse needs of companies across various industries. This platform simplifies the process of finding and purchasing the right packaging solutions, offering both convenience and choice.

By harnessing the power of a wide supplier network, Amazon Business delivers an extensive range of packaging options, from bulk containers to specialized wrapping materials. Whether you need sturdy boxes for shipping, protective padding for fragile items, or custom packaging for a unique product, Amazon Business is a one-stop-shop for all packaging essentials.

Businesses can benefit greatly from the platform's features like bulk pricing, easy reorder, and fast delivery, which are particularly beneficial for small to medium-sized enterprises looking to manage costs and maintain efficient operations.

Additionally, Amazon Business provides an opportunity to save up to 28% on purchases by making full use of GST input tax credits. This is a financial advantage that can help optimize businesses’ expenditures on packaging materials.

Ensuring compliance and quality, many of the packaging materials offered on Amazon Business meet necessary industry standards. This gives businesses peace of mind, knowing that their packaging choices align with legal requirements.

By choosing from eco-friendly and sustainable options available on Amazon Business, companies can also align their packaging needs with their environmental values, an aspect customers increasingly look for when making purchasing decisions.

Amazon Business stands as a valuable resource for diverse and quality packaging materials, helping businesses meet the demand for cost-efficient, sustainable, and compliant packaging solutions.

Recycling and Reusability of Common Packaging Materials

The concepts of recycling and reusability play a central role in the lifecycle of packaging materials. These practices are essential for conserving resources, reducing waste, and minimizing the environmental footprint of packaged goods.

Most common packaging materials, such as paper, cardboard, glass, metal, and certain types of plastics, offer opportunities for recycling. Paper and cardboard can be reprocessed multiple times into new paper products, while glass and metals like aluminum and steel can be recycled indefinitely without degradation of their inherent properties.

Plastics, although variable in their recyclability, also contribute to the recycling stream. Innovations in plastic materials aim to improve their recyclability, and the use of recycled plastics in new packaging continues to grow, supporting circular economy principles.

Reusability is another aspect that contributes to packaging sustainability. Many packaging types are designed to be reused several times before they enter the recycling process. Examples include durable containers that can be repurposed or higher-quality paper bags that withstand multiple uses.

Businesses and consumers alike are encouraged to participate in recycling programs and consider reusability when selecting packaging materials to help close the loop and foster a sustainable packaging ecosystem.

Prioritizing the recycling and reusability of common packaging materials not only protects the environment but also builds a foundation for responsible consumption and production.

Packaging Materials and Product Safety: What You Need to Know

Product safety is paramount when it comes to packaging materials. The right packaging not only ensures that the product reaches the consumer intact but also maintains its quality and usability throughout its intended shelf life.

Material selection must account for the chemical compatibility between the packaging and the product, particularly for food, beverages, and pharmaceuticals. Certain materials can react with the contents, potentially compromising product integrity or safety.

Physical protection is another critical consideration. Packaging should be sturdy enough to withstand shipping and handling stresses, including impacts, vibrations, and compressive forces. Manufacturers must meticulously evaluate the mechanical properties of packaging materials to prevent damage during transit.

Barrier properties are also vital, as some products may be sensitive to oxygen, moisture, or light. Using materials with appropriate barrier qualities can prevent spoilage and extend the product's life.

Regulatory compliance ensures that packaging materials meet specific standards and guidelines for safety. Adhering to these regulations is essential not only for consumer protection but also to avoid legal repercussions and brand damage.

Information transparency, such as labeling and traceability, is equally important. Adequate labeling provides consumers with critical product information and instructions, while traceability allows for accountability and management of recalls if necessary.

A comprehensive understanding of packaging materials and their interaction with products is essential in safeguarding consumer safety and maintaining product efficacy.

Cost-Effective Packaging Solutions for Businesses

For businesses across sectors, finding cost-effective packaging solutions is crucial for maintaining profitability while not compromising on quality and performance. The key is to strike a balance between the necessary features and the overall cost implications for the business and the consumer.

One approach to achieve cost-effectiveness is through minimalistic packaging. This strategy reduces material use and waste by focusing on the essentials required to protect and present the product effectively.

Bulk purchasing is another way businesses can save on packaging costs. Many suppliers offer discounts for large orders, which can be a significant cost saver, especially for businesses with high-volume packaging needs.

Opting for multi-functional packaging that combines shipping and retail display capabilities can also reduce the need for additional materials and processes, trimming down costs further.

Investing in durable and reusable packaging might have a higher initial outlay, but it can result in long-term savings by minimizing the need for frequent replacements.

For businesses looking to save on the purchase of packaging materials, platforms like Amazon Business can offer competitive pricing and the ability to buy in bulk, potentially aligning with their financial goals.

Implementing cost-effective packaging solutions offers a competitive edge to businesses by allowing them to streamline operations, reduce expenses, and offer better value to the end consumer.

Compliance and Regulations in Packaging Materials

Navigating the complex world of compliance and regulations is a critical aspect of selecting packaging materials. Various industries are governed by specific standards that ensure safety, quality, and environmental stewardship.

Food and pharmaceutical packaging, for example, are subject to stringent regulations to prevent contamination and protect public health. Materials used for these purposes must be food-grade or pharma-grade, confirming they are safe for direct contact with consumables and medications.

Environmental regulations also play a significant role in material selection. Legislation such as restrictions on single-use plastics or requirements for recycled content are influencing the packaging industry to innovate towards more sustainable solutions.

International trade involves additional layers of regulation, including compliance with import and export laws pertaining to packaging. This may involve certifications regarding the origin of materials, sustainability credentials, and adherence to foreign market standards.

Understanding and staying current with applicable local, national, and international regulations is not only legally necessary but also critical in building consumer trust and safeguarding brand reputation.

Adhering to compliance and regulations in packaging materials is essential for legal conformity, consumer protection, and demonstrating a company's dedication to responsible practices.

The Future of Packaging: Trends to Watch Out For

The packaging industry is evolving rapidly, with future trends largely shaped by technological advancements and changing consumer preferences. Keeping an eye on these trends is crucial for businesses to stay ahead and adapt to the dynamic market landscape.

One major trend is the rise of smart packaging. This involves incorporating technology such as QR codes, NFC, and RFID tags that add functionality beyond containment and protection. It enables features like tracking, interactive consumer engagement, and freshness monitoring.

Another significant trend is sustainable packaging. With a growing awareness of environmental issues, more companies are moving towards recyclable, compostable, and biodegradable materials. Innovations in this space include the development of plant-based plastics and the elimination of non-recyclable components.

Personalization and customization are also becoming increasingly important. Advances in printing technology allow for small-run batches with individualized designs, catering to the desire for unique and customizable packaging experiences.

Automation in packaging is another area of growth. The implementation of machines and robots can lead to increased efficiency, precision, and cost savings, which is highly attractive in labor-intensive packaging operations.

Moreover, the reduction of packaging waste is leading to minimalist designs that maintain protection and aesthetics while using fewer resources, supporting a less-is-more philosophy.

Staying abreast of trends such as smart packaging, sustainability, personalization, automation, and waste reduction will be key to navigating the future of packaging.

Conclusion: Making Informed Choices in Packaging Materials

In conclusion, the selection of packaging materials is a decision that carries significant implications for businesses. It determines the safety, integrity, and shelf life of products, while also reflecting the brand's values and commitment to sustainability.

The variety of materials available presents businesses with numerous options, each with its unique features and benefits. The choice should be guided by a thorough assessment of product needs, market demands, brand identity, and environmental considerations.

Making informed choices in packaging requires staying up-to-date with industry trends, advancements in material science, and regulatory changes. It also demands a proactive approach to embracing innovation, especially in the realms of sustainability and technology.

As the packaging industry continues to evolve, companies that prioritize adaptability and informed decision-making will be best positioned to succeed in a competitive marketplace. Comprehensive knowledge of packaging materials will remain a cornerstone of product strategy and brand development.

Ultimately, the mastery of selecting the right packaging materials is essential in creating products that are not only appealing and safe but also responsible and forward-thinking.

Essential FAQ on Packaging Material Selection

What Are the Most Common Types of Packaging Materials?

The most common types of packaging materials include plastic, cardboard, glass, metal, and biodegradable options. Each material has distinct advantages and is chosen based on factors like product type, durability, cost, and sustainability.

How Do I Choose the Right Packaging Material for My Product?

To choose the right packaging material, consider the product's size, shape, and fragility. Factor in the need for protection against moisture, air, or light. Additionally, reflect on packaging's environmental impact, your budget, and any regulatory compliance requirements.

Why Is Sustainability Important in Packaging Material Choices?

Sustainability in packaging materials is important to reduce environmental impact, conserve resources, and respond to increasing consumer demand for eco-friendly options. Choosing sustainable materials can also help businesses comply with regulations and improve brand image.

What Are Some Eco-Friendly Packaging Alternatives?

Eco-friendly packaging alternatives include paper and cardboard made from recycled content, plant-based plastics, biodegradable packing peanuts, and materials like mushroom mycelium and seaweed extract. These alternatives are designed to decompose or be recycled more efficiently.

Can Packaging Materials Be Both Durable and Sustainable?

Yes, it's possible for packaging materials to be both durable and sustainable. Materials like glass and metal are recyclable and can protect products effectively without losing quality. Advances in bioplastics and recyclable plastics are also enhancing durability while being more eco-friendly.