Understanding Food Grade Production Facilities: An Overview

Food grade production facilities are specialized environments where the safety and integrity of food packaging and processing must adhere to stringent regulations. These facilities are designed to prevent contamination and ensure that all food products are safe for consumption. Understanding the framework and characteristics of these facilities is fundamental for anyone involved with the production and packaging of food items.

At its core, a food grade production facility must conform to both national and international safety standards, such as those set by the Food and Drug Administration (FDA) in the United States and similar regulatory bodies worldwide. These standards govern everything from the materials used in construction to the procedures for handling and processing food products. Facilities must be constructed using non-toxic materials that are resistant to corrosion and easy to clean.

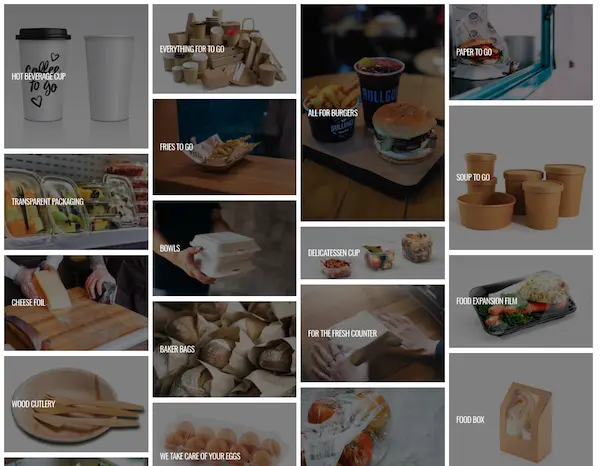

With our network with packaging suppliers along with a huge international network, we provide customizable logistic packaging services as per the needs and requirements of our clients, in order to maintain continuous product development and greatly reduce the spending for packaging solutions.

Furthermore, these facilities are required to implement a systematic approach to managing food safety risks, known as Hazard Analysis and Critical Control Points (HACCP). This involves identifying potential hazards that could occur in the food production process and establishing critical control points where measures can be applied to prevent or eliminate these risks.

In addition to physical and procedural regulations, there is a strong emphasis on maintaining a clean and hygienic environment within these facilities. This includes regular sanitation of all equipment, surfaces, and areas where food is processed or stored. Air quality and temperature control are also critical factors that must be meticulously managed to prevent the growth of pathogens and spoilage organisms.

Understanding these basic principles is essential for maintaining the integrity and safety of food products. By adhering to these standards, food grade production facilities can ensure that the products they produce are both safe and of high quality, thereby protecting consumers and upholding the facility's reputation in the food industry.

Key Hygiene Standards in Food Grade Production

Maintaining rigorous hygiene standards is crucial in food grade production facilities to ensure the safety and quality of food products. These standards are devised to minimize the risk of contamination and ensure that all operational practices adhere to the highest levels of cleanliness and sanitation.

One of the key hygiene standards includes **regular and thorough cleaning and sanitizing** of all equipment, tools, and surfaces. This standard is imperative to remove any food residues, dirt, and potential pathogens that could lead to food safety issues. The choice of cleaning agents and their usage protocol must be appropriate for the specific materials and surfaces within the facility to avoid chemical contamination.

Another significant standard is the **control of cross-contamination** between raw and cooked products. Facilities must have designated areas and equipment for handling different types of food products. Additionally, the flow of personnel and materials through the facility must be carefully managed to prevent cross-contact between different food and non-food zones.

Personal hygiene of employees is also vital. This includes rigorous protocols for hand washing, use of appropriate protective clothing like gloves and hairnets, and regular health checks. Facilities must ensure all staff are well-trained in these protocols and understand their critical role in maintaining hygiene standards.

Lastly, pest control is an essential standard, as pests pose a significant risk of contamination. Effective pest management strategies must be in place, including regular inspections and treatments, to prevent any infestation that could compromise food safety.

Adhering to these key hygiene standards helps ensure that food grade production facilities operate under the safest conditions possible, significantly reducing the risk of foodborne illnesses and ensuring consumer trust in their products.

Pros and Cons of Implementing Rigorous Hygiene Practices in Food Production

| Aspect | Pros | Cons |

|---|---|---|

| Use of High-quality Sanitizers | Effectively reduces microbial contamination on surfaces. | Higher ongoing costs and potential chemical exposure. |

| Regular Equipment Maintenance | Prevents equipment malfunctions and contamination. | Can be time-consuming and disrupt production schedules. |

| Comprehensive Staff Training | Ensures all employees understand and practice safe food handling. | Requires investment in training resources and time. |

| Strict Personal Hygiene Rules | Limits introduction of pathogens from outside sources. | May be viewed as intrusive or demanding by staff members. |

| Audit and Certification | Gains trust from consumers and regulators. | Can be costly and stressful for the management team. |

Best Practices for Ensuring Quality in Food Production

Ensuring quality in food production is not just about adhering to regulatory standards; it involves the implementation of best practices that go beyond basic compliance. These practices are designed to enhance product consistency, safety, and overall consumer satisfaction.

One of the best practices is the **implementation of advanced quality management systems** (QMS) like ISO 22000 or the Safe Quality Food (SQF) program. These systems provide a comprehensive framework for systematically managing food safety and quality, from supplier selection to finished product inspection.

**Continuous monitoring and testing** of products and processes is also critical. This includes regular sampling and analysis to ensure that all food products meet the required taste, texture, and safety standards before they reach the consumer. Utilizing statistical process control (SPC) techniques can aid in monitoring production processes and detecting deviations from set quality parameters.

**Employee training and engagement** are pivotal. Employees should not only be trained on compliance requirements but also on the importance of their roles in maintaining quality. Continuous education and training on the latest food safety and production technologies can empower employees to contribute to quality enhancements actively.

Maintaining a strong supplier relationship is another best practice. Facilities must ensure that their raw materials meet specified quality standards, which involves:

- Performing audits and assessments of suppliers.

- Establishing clear criteria for raw material acceptance.

- Fostering open communication channels for addressing quality issues.

Finally, leveraging technology can significantly enhance quality assurance in food production. This includes the adoption of automation and robotics for more precise and consistent food processing and packaging, thereby reducing human error and increasing efficiency.

By integrating these best practices, food grade production facilities can consistently produce high-quality products that meet both consumer expectations and regulatory requirements, marking a significant step towards sustainability and consumer trust.

Implementing Effective Cleaning Protocols

Effective cleaning protocols are paramount in maintaining the hygiene and safety standards necessary in food grade production facilities. Implementing these protocols involves a detailed, systematic approach tailored to the specific needs of each area of the facility.

**Development of a comprehensive cleaning schedule** is the first step. This schedule should detail:

- The frequency of cleaning required for each area of the facility.

- Specific cleaning tasks to be completed during each session.

- Designated personnel responsible for each task.

Choosing the **right cleaning agents and tools** is also crucial. Facilities should:

- Use food-safe disinfectants approved for food contact surfaces to avoid chemical hazards.

- Equip cleaning staff with tools that prevent the risk of physical contamination, such as non-abrasive scrubbers and single-use towels.

**Documenting cleaning procedures and outcomes** is essential for monitoring efficacy and areas needing improvement. Each cleaning session should be logged with details including:

- Time and date of the cleaning.

- Staff members involved.

- Products and equipment used.

- Any issues encountered and how they were resolved.

Lastly, **regular training sessions** for cleaning staff are vital. Training should cover both the practical aspects of cleaning and the importance of these protocols in maintaining food safety. Continuous updates on the latest cleaning techniques and hygiene standards ensure staff remain knowledgeable and effective.

Proper implementation of cleaning protocols not only ensures compliance with health and safety regulations but also reinforces a facility’s commitment to producing safe, high-quality food products.

The Role of Employee Training in Maintaining Standards

Employee training plays a crucial role in ensuring that the standards of safety and quality are consistently met in food grade production facilities. Effective training programs are fundamental to empower employees with the knowledge and skills they need to perform their jobs effectively and safely.

**Structured Onboarding for New Employees** is essential. Initial training should cover:

- Fundamental safety practices and the importance of maintaining hygiene.

- Overview of the production process specific to the facility.

- Proper use of machinery and handling of raw materials.

**Ongoing Educational Programs** should be implemented to keep pace with evolving industry standards and technologies. These programs might include:

- Regular updates on new regulations and quality standards.

- Advanced training on new equipment or technologies adopted by the facility.

- Workshops focusing on problem-solving and quality improvement processes.

Utilizing **Interactive Training Methods**, such as simulations and group workshops, can enhance learning and retention. This interactive approach encourages a more engaging learning environment and can be particularly effective in teaching complex procedures or in response training for potential emergency scenarios.

**Assessment and Feedback** are critical to the training process. Regular evaluations help determine the effectiveness of the training program and identify any gaps in knowledge. Feedback from employees can also guide the development of future training sessions, ensuring they are relevant and comprehensive.

The investment in employee training is reflected in the overall quality of the food products and the efficiency of production. Well-trained employees are not only more adept at meeting the required standards but also play a pivotal role in fostering a culture of safety and continuous improvement within the facility.

Regular Audits and Inspections for Compliance

Regular audits and inspections are critical components in ensuring compliance with health, safety, and quality standards within food grade production facilities. These assessments help to identify areas that require improvement and ensure that all operational practices meet the legal and industry standards.

Internal Audits: Conducting internal audits allows facilities to self-assess their compliance and operational efficiency. Key elements of internal audits include:

- Reviewing and evaluating adherence to all safety protocols and production processes.

- Identifying any discrepancies or non-conformities in the practices applied across different sectors of the facility.

- Implementing corrective actions to address identified issues promptly.

External Inspections: External audits are typically performed by third-party organizations or regulatory bodies. These inspections are crucial as they provide an unbiased review of the facility’s compliance with external standards. Essential aspects include:

- Thorough examination of both documentation and physical operations.

- Evaluation against global standards like ISO 22000 or local food safety regulations.

- Receiving certification or feedback that helps build trust with consumers and stakeholders.

Both types of audits are enhanced by using state-of-the-art technology. Using software for audit management can automate scheduling, data collection, and analysis, leading to more efficient and accurate audits. Tech tools like digital checklists and real-time reporting apps can streamline the process and reduce human error.

Furthermore, regular audits and inspections instill a culture of continuous improvement. Facilities that routinely evaluate and adjust their processes are better positioned to adapt to new regulations, enhance product quality, and uphold safety standards, ultimately leading to sustained compliance and operational excellence.

Technological Advancements in Food Grade Production

Technological advancements have significantly transformed the landscape of food grade production, enhancing both the efficiency and safety of processes. These innovations not only streamline operations but also improve the compliance and quality of the products.

Automation and Robotics: The integration of robotics in food production has led to greater precision in tasks such as filling, packing, and sorting. Automation reduces the human error factor and increases throughput, allowing for more consistent product quality and faster response times to market demands.

Advanced Sensing and Monitoring Technologies: Real-time monitoring systems equipped with sensors provide critical data on various parameters like temperature, humidity, and equipment performance. These systems help in maintaining the critical control points identified in the Hazard Analysis and Critical Control Points (HACCP) plan, ensuring products are produced within safe and controlled conditions.

Artificial Intelligence (AI) and Machine Learning: AI algorithms analyze patterns and predict potential flaws or system failures before they occur, making the production process more proactive rather than reactive. This predictive analysis helps in reducing downtime and improving the overall reliability of the production process.

Additionally, Blockchain Technology is revolutionizing traceability in the food supply chain. By providing a tamper-proof database, blockchain allows for transparent tracking of products from farm to table, ensuring the authenticity and safety of food products.

These technological advancements not only boost productivity but also enhance the capability of food grade production facilities to meet higher standards of quality and safety, ultimately benefiting both producers and consumers.

Case Studies: Success Stories from the Industry

Exploring case studies and success stories can provide valuable insights into effective strategies and practices within the food grade production industry. These examples highlight the tangible benefits of adopting rigorous standards, advanced technologies, and strategic planning.

Case Study 1: Implementation of Advanced Traceability Systems

A leading dairy company introduced blockchain technology to enhance the traceability of their product line from farm to grocery shelves. This move not only improved the transparency of the sourcing and processing paths but also significantly decreased the time required to track and trace any batch in case of a quality issue. As a result, trust among consumers increased, ultimately boosting the company's market reputation and sales.

Case Study 2: Automation in Packaging

A confectionery manufacturer invested in fully automated packaging lines equipped with AI-driven quality control systems. The integration of high-speed cameras and real-time analysis software allowed for immediate detection and removal of defective products. This led to a 30% reduction in product waste and a 20% increase in production efficiency, showcasing a strong return on investment from technological adaptation.

Case Study 3: Employee Training Programs

An international frozen foods company revamped its employee training program to focus on continuous learning and compliance with food safety practices. By using interactive e-learning tools and hands-on workshops, they were able to reduce safety incidents by 40% and enhance employee satisfaction and retention rates. This proactive approach in training reinforced a culture of safety and operational excellence within the facility.

These case studies demonstrate that investing in technology, rigorous standards, and employee development can lead to substantial improvements in product quality, safety, and operational efficiencies. Through these focused efforts, food grade production facilities can achieve notable success, setting industry benchmarks and inspiring others in the sector.

Conclusion: Continuous Improvement in Food Grade Facilities

In conclusion, maintaining high standards of hygiene and quality in food grade production facilities is not just about meeting regulatory requirements—it's about striving for excellence and continuous improvement. The integration of cutting-edge technologies, adherence to rigorous hygiene practices, comprehensive employee training, and regular audits and inspections are all critical elements that work synergistically to enhance the overall safety and quality of food products.

Continuous improvement in these facilities is a dynamic process that involves regular assessment, feedback, and adaptation. Implementing best practices from case studies and staying informed about technological advancements are instrumental in driving these improvements. As the food production industry evolves, so must the strategies employed by food grade production facilities.

The commitment to continuous improvement not only ensures compliance but also fosters innovation, efficiency, and consumer trust. Moreover, it prepares facilities to efficiently tackle future challenges that may arise from changes in consumer preferences, regulatory landscapes, or technological breakthroughs.

Ultimately, the goal is to sustain a high level of product quality and safety that not only satisfies the present demands but sets a higher standard for the future of food grade production.

FAQ: Key Best Practices in Food Production Facilities

What are the essential hygiene practices in food grade production facilities?

Essential hygiene practices include regular and thorough cleaning of all equipment and surfaces, management of cross-contamination risks, strict personnel hygiene protocols, and comprehensive pest control measures.

How often should cleaning protocols be executed in these facilities?

Cleaning protocols should be executed daily, with additional deep cleans scheduled periodically based on the specific needs of the facility and the nature of the production processes.

What role does employee training play in maintaining hygiene and quality?

Employee training is crucial, as it ensures that staff are fully aware of hygiene and safety standards. Effective training includes onboarding, ongoing education, and the use of interactive methods to enhance understanding and compliance.

Why is regular monitoring and testing important in food production?

Regular monitoring and testing are vital to ensure that all products meet safety and quality standards. This includes the analysis of hazard points, verification of cleaning effectiveness, and continuous inspection of production processes.

What best practices should be implemented for effective pest control?

Effective pest control involves a combination of preventative measures, regular inspections, and the use of appropriate treatments to eliminate risks. Facilities should also train staff to recognize signs of infestation and respond promptly to mitigate potential contamination.