Packaging Line

Packaging Line

Packaging Line

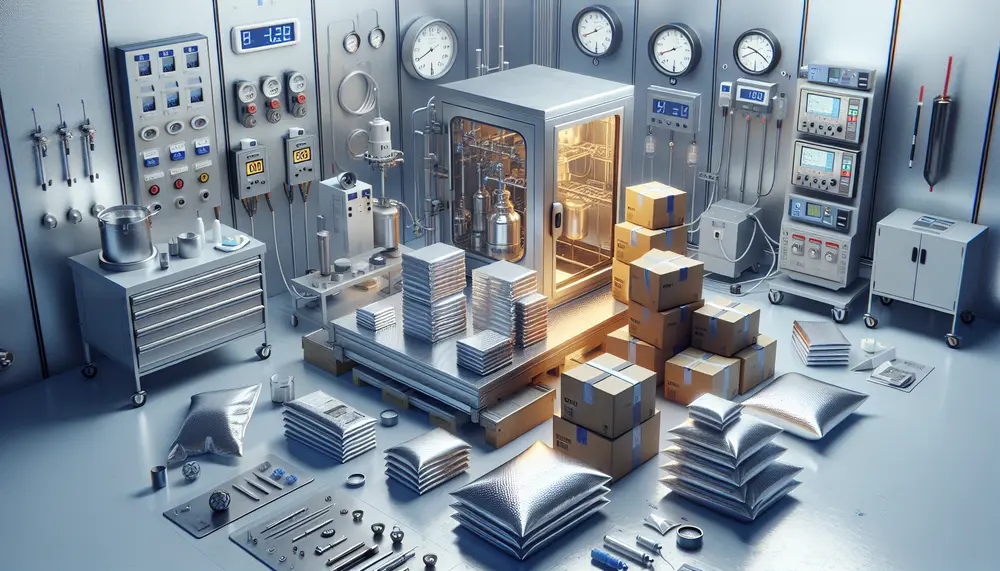

A Packaging Line is a series of machines and processes used to prepare products for shipment. It includes various stages like filling, sealing, labeling, and packing. Each step ensures the product is ready for transport and sale.

Components of a Packaging Line

A typical Packaging Line consists of several key components. These include filling machines, capping machines, labeling machines, and case packers. Each machine has a specific role in the packaging process.

Filling Machines

Filling machines are the first step in a Packaging Line. They fill containers with the product. For example, a liquid filling machine pours liquids into bottles.

Capping Machines

After filling, capping machines seal the containers. This step ensures the product stays fresh and prevents spills. For instance, a bottle capping machine places and tightens caps on bottles.

Labeling Machines

Labeling machines add labels to the containers. Labels provide important information like product name, ingredients, and expiration date. A labeling machine can apply labels quickly and accurately.

Case Packers

Case packers are the final step in a Packaging Line. They pack the filled, capped, and labeled containers into boxes. This makes the products ready for shipping and distribution.

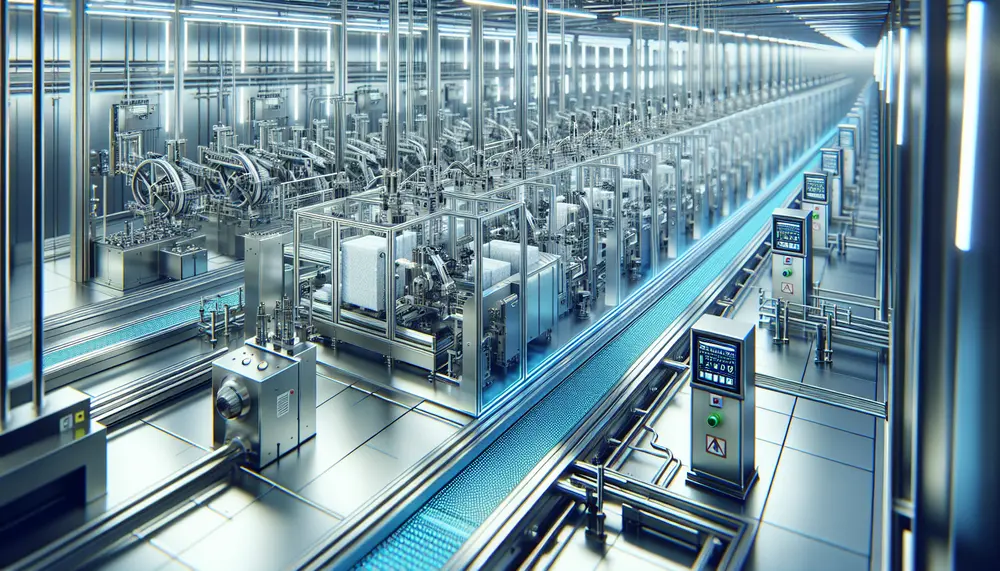

Benefits of a Packaging Line

A Packaging Line offers many benefits. It increases efficiency, reduces labor costs, and ensures consistent product quality. By automating the packaging process, companies can meet high demand and maintain standards.

Conclusion

Understanding a Packaging Line is crucial for anyone in the packaging industry. It involves various machines and steps that work together to prepare products for the market. Knowing each component helps in optimizing the packaging process.

Blog Posts with the term: Packaging Line

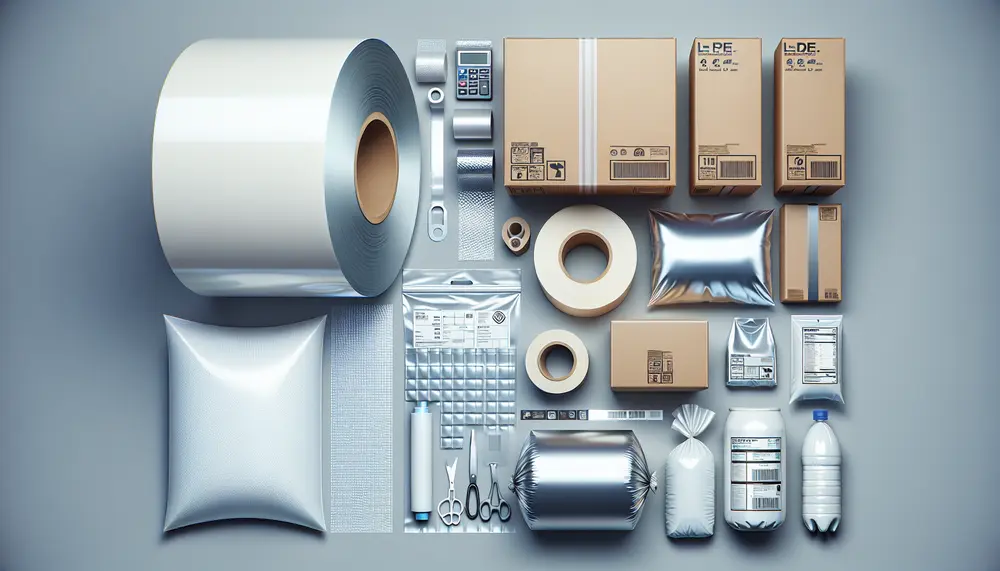

Packaging levels refer to the layers of packaging used from production to consumer, including primary (direct product contact), secondary (grouping and branding), and tertiary (bulk handling). Each level serves distinct purposes in protection, marketing, transportation, and regulatory compliance....

The packaging and technology revolution is transforming product protection, preservation, and presentation through intelligent systems, AR/VR experiences, digital printing for customization, with a focus on data security in smart packaging solutions. This intersection of fields offers innovation opportunities across industries. Technology's...

Duplex paper is a two-layered packaging material known for its printability and structural integrity, widely used across industries due to its visual appeal and sturdiness. It's also eco-friendly, being recyclable and often made from sustainable sources. Advancements in duplex paper manufacturing...

Heat resistant packaging materials are designed to protect contents from high temperatures during transportation or storage, with various forms for different applications and levels of protection. Innovations aim to enhance heat resilience while considering cost-effectiveness and environmental impact. Thermal stability...

Packaging technicians play a crucial role in product delivery, operating machinery and selecting materials while prioritizing safety and quality. They require skills like basic math, GMP knowledge, analytical thinking, computer proficiency, teamwork, and communication to succeed. The job of a packaging...

Packaging technology is crucial for product protection, shelf life extension, and consumer information; it involves material science and design innovation to create sustainable solutions. Cutting-edge materials like bioplastics and smart substances are shaping the industry's future with enhanced functionality and...

Packaging design combines aesthetics and functionality, focusing on the product, brand identity, consumer appeal, and compliance with regulations. Good packaging balances visual attractiveness with practicality to enhance user experience and encourage loyalty. Effective packaging requires a balance of clear messaging, simplicity...

Affordable packaging focuses on cost-effective, quality solutions that balance price with durability and sustainability. It involves exploring materials like bioplastics, optimizing design for minimalism and efficiency, and staying updated on industry trends to reduce costs without sacrificing customer experience or...

Flexible packaging in the pharmaceutical industry enhances protection, usability, and sustainability by offering versatile solutions for various medications while reducing costs and environmental impact. Its applications range from oral medications to injectables, providing tailored options that improve product safety and...

A pharmaceutical packaging technician is essential in the healthcare industry, responsible for accurately packaging medications while adhering to strict regulations and maintaining safety standards. Their role involves operating machinery, manual tasks, quality control checks, and effective communication within teams to...

Advanced packaging machines enhance efficiency and productivity in modern production lines by automating tasks, ensuring precision, and enabling cost savings. They are crucial for businesses to stay competitive and meet industry standards. High-efficiency packaging machines feature user-friendly interfaces, modular designs, precise...

LDPE film is a flexible, transparent thermoplastic used extensively in packaging for its chemical resistance and moisture barrier properties, which are crucial across industries like food, pharmaceuticals, and agriculture. It stands out due to its recyclability and balance of protection,...

Packaging research and design are essential for aligning with consumer expectations, market trends, and environmental considerations to enhance user experience and brand loyalty. The synergy between research and creative solutions results in packaging that resonates emotionally with consumers while effective...

Pharmaceutical packaging is essential for maintaining the safety, integrity, and effectiveness of medications by protecting them from contamination, degradation, and tampering while ensuring they remain effective throughout their shelf life. It involves using various materials like glass, plastics, metals, and...

Pharmaceutical packaging equipment is essential for maintaining the safety, integrity, and efficacy of medications by adhering to strict regulatory standards. This includes a variety of machines like blister pack machines, bottle filling machines, and labeling systems that ensure protective containment...