Table of Contents:

Understanding Heat Resistant Packaging Materials

When we talk about heat resistant packaging materials, we're referring to the specialized materials designed to withstand high temperatures without degrading, melting, or undergoing any form of structural compromise that could potentially damage the contents they hold. It's not just about keeping an item intact; it's a matter of ensuring that the product reaches the consumer in peak condition, irrespective of the external temperature challenges it may face during transportation or storage.

These materials come in various forms, each serving a unique purpose and offering different levels of thermal protection. For example, some materials are intended for single-use applications, such as shipping perishable goods, while others are made for repeated use in industrial contexts. Common materials include certain plastics which, through the addition of heat stabilizers, gain increased resistance to thermal conditions. Likewise, glass and metal can serve as barriers to heat, but they often require additional insulating components to maintain user safety and product usability.

To understand the science behind heat resistance, one must look at the molecular stability these materials provide at elevated temperatures. The key lies in maintaining the integrity of the molecular structure, which ensures that the material's physical properties remain unchanged despite exposure to heat. This stability is paramount in industries like food service, electronics, healthcare, and automotive, where maintaining a certain temperature range is critical to product functionality and safety.

Innovation in packaging technologies continuously pushes the boundaries of what these materials can endure. Development into new composites and coatings aims to further enhance heat resilience while also focusing on aspects like weight reduction, cost-effectiveness, and environmental impact. As we advance, the dialogue around heat resistant packaging materials becomes more sophisticated, considering not just resistance to temperature, but also the holistic lifecycle of the packaging from production to disposal.

The Importance of Thermal Stability in Packaging

Thermal stability in packaging is a crucial aspect that ensures the longevity and efficacy of a product. It protects the contents from the adverse effects of temperature fluctuations which can lead to spoilage, reduced efficacy, or complete failure of the enclosed product. Especially for pharmaceuticals or biochemical products, where precise temperature control is vital to maintain the therapeutic properties, thermal stability can be a matter of life or death.

Moreover, as global distribution networks expand, products are increasingly exposed to varying climatic conditions. Effective thermal management within packaging systems ensures that goods can be transported across different climate zones without degradation. This is not only important for quality control but also for regulatory compliance, as many industries have strict guidelines about temperature conditions for goods in transit.

In the realm of consumer experience, packaging that offers reliable thermal stability can also enhance brand reputation. Customers expect products to perform as promised, regardless of external temperature stresses. A product that arrives compromised due to inadequate thermal protection can erode consumer trust and affect repeat business.

The technological advances in this sector not only safeguard product integrity but also contribute to greater efficiency in the supply chain. With robust thermal solutions in place, companies can reduce costs associated with returns, waste, and insurance for temperature-sensitive goods, thereby optimizing overall business performance.

Comparative Analysis of Heat-Resilient Packaging Options

| Aspects | Pros | Cons |

|---|---|---|

| Material Durability | Can withstand high temperatures without deforming or releasing harmful substances. | Heat-resistant materials can be more costly and less flexible than standard packaging materials. |

| Environmental Impact | Potentially reusable or recyclable, reducing long-term waste. | Production processes for heat-resistant materials may have a higher environmental impact. |

| Product Safety | Ensures the integrity and quality of the product during transportation and storage. | May require additional safety testing, contributing to increased costs and longer time to market. |

| Cost Efficiency | Long-term savings through reduced product damage and loss. | Initial investment is higher than with standard packaging solutions, impacting budget allocation. |

| Market Adaptability | Opens new market opportunities for products that require heat control. | Companies may need to invest in new technologies and training to properly handle these materials. |

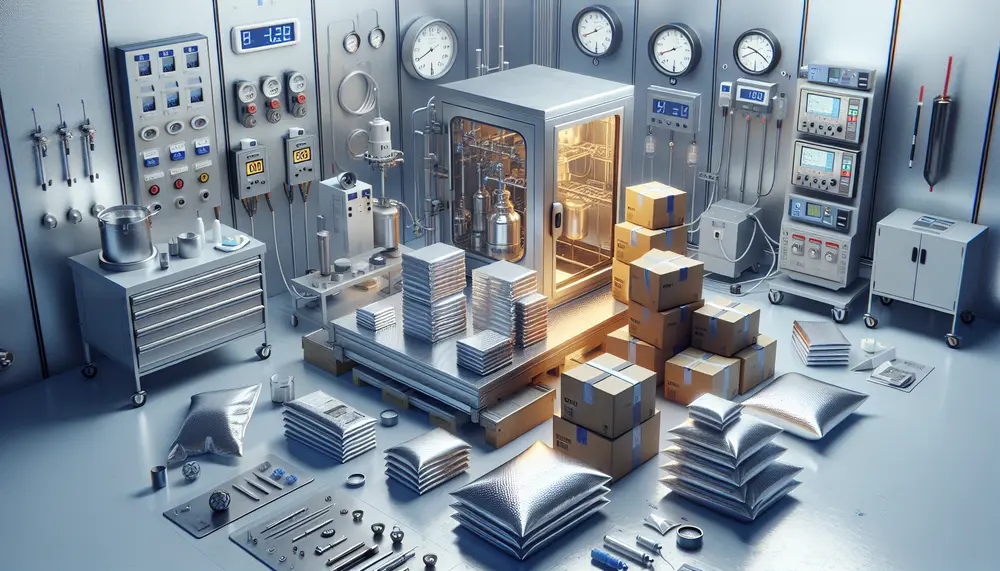

Innovative Packaging Solutions for High-Temperature Environments

To navigate the complexities of high-temperature environments, the packaging industry has embraced innovation with open arms. Cutting-edge packaging solutions integrate materials and technologies specifically engineered to endure harsh thermal conditions while preserving the integrity of the products within.

Recent developments in this field have seen the rise of smart packaging that incorporates temperature indicators or time-temperature integrators. These indicators provide immediate visual feedback on the thermal history of the product, informing stakeholders if the goods have been exposed to temperatures beyond their tolerance levels.

Another novel approach is the use of phase change materials (PCMs) that absorb or release latent heat to maintain a constant temperature. These materials can be incorporated into packaging liners or panels and are particularly useful for products that require strict temperature controls over an extended period.

Multilayered insulation is also at the forefront of these innovative solutions. By combining different materials with unique thermal properties, these multilayered structures provide superior insulation, reflecting radiant heat while minimizing conductive and convective heat transfer.

Aerogels, known for their low thermal conductivity, are being used in some high-performance packaging solutions. Their porous structure makes them extremely lightweight yet robust enough to offer exceptional insulation in a thin form factor.

Finally, the packaging industry is also exploring the potential of advanced coatings that can reflect infrared radiation, preventing heat from penetrating the packaging and affecting the product.

These advanced solutions illustrate the packaging industry's commitment to going beyond traditional methods, turning to science and technology to ensure that temperature-sensitive products can withstand the rigors of high-temperature environments.

Selecting the Right Materials for Heat-Sensitive Products

The selection of appropriate materials for packaging heat-sensitive products is a pivotal decision that impacts product safety, shelf life, and user satisfaction. It is not enough to simply choose the most robust material; the packaging must also be tailored to the product's specific thermal requirements and the expected environmental conditions.

For perishable goods, such as food and certain pharmaceuticals, reflective materials like aluminum may be utilized to deflect heat. On the other hand, products prone to chemical degradation might need packaging materials that offer a barrier against oxygen and humidity, in addition to temperature control.

Insulating foams and fibers, which trap air or inert gases within their structure, can be implemented for items that require a buffered thermal environment. These materials slow down the transfer of heat, keeping the packaged goods within a safe temperature range for longer periods.

Choosing the right material also includes considering the total packaging system. This might involve a combination of primary, secondary, and tertiary packaging with complementary thermal properties to ensure full protection throughout the product’s journey from manufacturer to end-user.

Lastly, there's a growing emphasis on sustainable materials with lower environmental impacts. Innovations in bioplastics and recyclable or compostable insulating materials are allowing businesses to provide heat-sensitive packaging solutions that are also eco-friendly.

Meticulous selection, considering both performance and sustainability, will be the cornerstone of future packaging strategies for heat-sensitive products.

Challenges in Designing High-Temperature Packaging

Designing packaging for high-temperature applications encompasses several distinct challenges that require careful consideration and innovative problem-solving. One of the foremost difficulties is striking a balance between functionality and cost. While advanced materials may offer superior protection, they often come with a higher price tag. Manufacturers must navigate these costs without compromising product safety or price competitiveness.

Compatibility with the product is another key challenge. The chosen packaging materials must not only bear the brunt of heat but also avoid chemically reacting with the product. This is particularly critical in the food and pharmaceutical industries where such interactions could alter the taste or therapeutic value of the contents.

The durability of packaging over time, especially under constant exposure to high temperatures, also poses a significant challenge. Materials that may perform well initially can suffer from decreased effectiveness due to thermal aging, making it essential to select materials based on both immediate and long-term requirements.

In addition, logistical considerations can complicate the packaging design process. The packaging must be robust enough to handle the stresses of transportation and storage, which often includes a variety of temperature ranges and physical impacts. It has to maintain integrity in potentially variable climatic conditions.

Another challenge is compliance with regulations which can vary significantly by region and industry. Ensuring that packaging meets all legal requirements for safety, labeling, and material use can add complexity to design and material selection processes.

Lastly, with increased consumer awareness and demand for sustainability, finding environmentally friendly options suitable for high-temperature environments becomes equally important. Designers need to reconcile the need for thermal resistance with ecological concerns, aiming to reduce the carbon footprint of packaging materials.

Addressing these challenges demands not only technical expertise but also a forward-thinking approach to continually evolve and improve high-temperature packaging solutions.

Case Studies: Successful Heat-Resistant Packaging in Action

Observing successful heat-resistant packaging solutions in real-world scenarios helps elucidate the impact of innovative designs and material selection. Case studies exemplify how companies have successfully overcome the challenges of maintaining product integrity in extreme temperatures.

An example is the use of specialized packaging for shipping frozen foods. These packaging solutions often involve a combination of insulating materials and refrigerants like gel packs or dry ice. The insulating material not only needs to withstand low temperatures but also prevent the rapid increase in temperature during transit.

Another case study revolves around electronics, particularly the shipment of lithium-ion batteries. These products are vulnerable to high temperatures that can lead to overheating and potentially dangerous scenarios. Utilizing flame-retardant materials and designing packaging with proper ventilation has been key to mitigating risks.

In the pharmaceutical sector, transporting vaccines has presented unique challenges. Manufacturers have turned to advanced packaging with PCMs for their ability to keep vaccines within their precise temperature range, ensuring they remain effective upon delivery.

On the industrial front, transporting machine components that can become extremely hot during operation has been facilitated by the use of heat-absorbing materials which not only protect handlers from burn risks but also avoid the potential for heat damage to other goods in transit.

These case studies demonstrate that, with the right combination of materials and design innovations, packaging can be effectively tailored to meet the heat-resistance needs of various products, providing an invaluable safeguard against temperature-related issues.

Maintaining Product Integrity with Advanced Thermal Packaging

Maintaining the integrity of products when faced with extreme temperatures calls for advanced thermal packaging solutions. These solutions are designed to manage the internal conditions of the packaging, ensuring that products remain within the optimal temperature range throughout their journey.

Significant strides are being made with temperature-controlled packaging, employing data loggers and IoT technologies to continuously monitor conditions and maintain a record of any temperature excursions during transit. This technology enables immediate intervention when temperatures breach predetermined thresholds, thereby securing product integrity.

Active packaging systems represent another method for supporting product integrity in transport. These systems actively regulate the temperature within the packaging using electronic or chemical means. Their use has been particularly prominent in safeguarding sensitive electronics and life-saving medical substances.

Moreover, passive thermal packaging systems utilize specially designed insulating layers and PCMs to maintain stable temperatures without external power sources or mechanical intervention. Such systems are often preferred for their reliability, cost-efficiency, and ease of use.

The combination of innovative materials, such as vacuum insulated panels and radiant heat barriers, further improves the effectiveness of thermal packaging. These materials provide superior insulation and are increasingly becoming more accessible and practical for mainstream shipping needs.

Through ongoing research and development, packaging technologies continue to evolve, aiming to provide even more reliable solutions to ensure product integrity, regardless of temperature challenges.

The Future of Packaging in High Heat Applications

The landscape of packaging for high heat applications is on the cusp of transformation, driven by continuous advancements in technology and materials science. Forward-thinking trends are shaping a future where packaging is not only more resistant to high temperatures but also smarter and more sustainable.

The integration of smart sensors and connectivity is set to revolutionize packaging for high heat scenarios. With real-time temperature monitoring and tracking capabilities, stakeholders will be able to respond proactively to potential heat-related issues, enhancing the safe delivery of sensitive products.

Nanotechnology is expected to play a pivotal role in the development of cutting-edge packaging materials. The manipulation of matter at an atomic level promises new composites with exceptional heat resistance and minimal ecological impact.

Biodegradable and compostable materials are also making headway as part of the solution to packaging waste. Innovations in this area could lead to new forms of high-performance packaging that leave a minimal environmental footprint.

3D printing technology offers the promise of fully customizable packaging solutions. With this technology, packaging can be tailored precisely to a product's size and thermal protection needs, reducing material waste and optimizing packaging efficiency.

As consumer demand for sustainability grows, the industry is also exploring the possibility of reusable and returnable thermal packaging. Such circular economy models could significantly reduce waste and resource consumption.

The future of packaging in high heat applications is a dynamic field, with exciting progress on the horizon that aims to deliver enhanced protection, greater efficiency, and reduced environmental impact.

Best Practices for Storing and Transporting Heat-Sensitive Items

Effective storage and transportation of heat-sensitive items are pivotal to preserving their quality and function. Implementing best practices is crucial for achieving this goal. Here are some recommended strategies:

- Conduct a thorough risk assessment of the supply chain to identify potential heat exposure points and implement strategies to mitigate these risks.

- Use insulated containers with thermal properties appropriate for the specific heat sensitivity of the items being stored or transported.

- Incorporate temperature monitoring tools to track and maintain the desired temperature range, allowing for timely corrective actions if needed.

- Arrange items within the packaging to ensure even temperature distribution and avoid direct exposure to heat sources.

- Optimize shipping routes and timing to minimize exposure to high temperatures, such as avoiding shipping during the hottest times of the day or year.

- Train personnel on the proper handling of heat-sensitive items to ensure they are aware of the practices that maintain product integrity.

- Regularly review and update these practices to incorporate new technologies and insights from past experiences to continually improve the thermal protection of products.

Adhering to these best practices ensures the safe storage and transport of heat-sensitive items, maintaining their integrity and extending their usability.

Evaluating the Performance of Heat-Resistant Packaging Solutions

Evaluation is key to ensuring that heat-resistant packaging solutions deliver on their promise. This process involves rigorous testing and analysis to verify that the packaging meets the required performance standards.

- Begin with laboratory testing to assess the material's physical and chemical properties under high-temperature conditions. This includes tests for melting point, thermal degradation, and structural integrity.

- Conduct real-world trials that simulate the conditions the packaging will face during shipping and storage scenarios. This helps identify any discrepancies between laboratory results and actual performance.

- Implement standardized testing protocols such as ASTM and ISO to ensure consistency and comparability of data across different materials and designs.

- Analyze thermal imaging data to visualize the effectiveness of the insulation and identify heat transfer points that could become potential vulnerabilities.

- Gather feedback from the end-users as well as supply chain partners to gain insights into the real-world efficacy and practicality of the packaging solutions.

Constant evaluation and optimization based on comprehensive testing are necessary to assure the reliability of heat-resistant packaging solutions in safeguarding product integrity against high-temperature challenges.

Regulatory Considerations for High-Temperature Packaging Materials

When selecting and designing high-temperature packaging materials, regulatory considerations play a crucial role. Compliance with relevant laws and guidelines is essential for ensuring safety, legality, and market access.

- Identify and adhere to international and regional regulations that pertain to packaging materials, such as those specified by the FDA, EU, and other regulatory bodies.

- Understand the specific safety standards required for different product categories, as the standards for food packaging may differ markedly from those for industrial goods.

- Ensure that materials used are not only heat-resistant but also conform to toxicity and health standards, reducing the risk of chemical leaching under high temperatures.

- Maintain thorough documentation of all compliance efforts and certifications for materials and processes used, making this information readily available for inspection if required.

- Stay abreast of changes in legislation, as regulatory frameworks can evolve rapidly in response to new scientific findings and public health concerns.

Incorporating these regulatory considerations from the outset of material selection and package design processes is fundamental for creating high-temperature packaging that meets the complex requirements of current and future markets.

Sustainability and Eco-Friendliness in Heat-Resistant Packaging

The imperative for sustainability in the packaging industry encompasses the need for eco-friendly options in heat-resistant packaging. As concern for the environment grows, the responsibility to develop packaging solutions that are not only effective but also sustainable becomes more pronounced.

- Research into biobased materials is yielding new forms of heat-resistant packaging that can biodegrade or be composted after use, minimizing environmental impact.

- Innovation in recyclable materials is leading to the creation of heat-resistant packaging that consumers can easily recycle, helping to reduce the amount of waste sent to landfills.

- Manufacturers are exploring reusable packaging systems that prolong the lifecycle of packaging materials and reduce the need for single-use solutions.

- Assessment of the entire product lifecycle, from raw material extraction to disposal or recycling, is critical to ensure the true sustainability of packaging materials.

- Engaging in partnerships with sustainability certification bodies can aid companies in achieving recognized eco-friendly standards and gaining consumer trust.

Integrating these sustainability considerations into the design and implementation of heat-resistant packaging reflects a commitment to protecting the environment while still providing the thermal protection needed for sensitive products.

Customizing Packaging Solutions for Extreme Heat Conditions

The unique demands of extreme heat environments necessitate custom packaging solutions tailored to withstand such intense conditions while safeguarding the contained products. Personalized packaging designs enable accommodation of specific thermal challenges, leading to increased protection and performance.

Working closely with clients to understand the products' exact requirements is the first step in developing bespoke packaging. This collaboration ensures that the solutions developed are aligned with the products' heat tolerance, size, shape, and transportation conditions.

Material selection is then tailored, with options ranging from high-grade insulators to specialized reflective materials, each chosen for its ability to perform under the heat levels anticipated. Innovative materials such as high-temperature-resistant polymers and ceramics are examples of the kind of custom options available.

Design features such as thermal barriers, seals, and buffering layers are incorporated to handle specific stress points identified during the assessment phase. The use of multi-layer insulation or the integration of phase change materials may also be considered to further enhance the thermal resistance.

Prototyping and iterative design processes are then used to refine the packaging, with test iterations enabling adjustments based on performance feedback. This iterative process is critical in achieving a design that is not only heat-resistant but also practical for manufacturing and use.

Ultimately, customizing packaging for extreme heat conditions aids in overcoming the limitations of standard packaging options, providing a more focused approach to product safety and integrity in demanding thermal environments.

Technological Advancements in Heat Barrier Packaging

Technological progress continues to revolutionize the capabilities of heat barrier packaging, pushing the limits of thermal insulation and protection. These advancements contribute significantly to enhancing the safety and shelf life of temperature-sensitive products.

Developments in material science have given rise to new composites specifically engineered to act as superior heat shields. These may integrate aerogel technology, famed for its low thermal conductivity, or leverage metallic foils for their reflective properties.

Breakthroughs in active cooling systems permit the inclusion of compact, battery-operated refrigeration units within packaging, which can be programmed to activate when temperatures reach a critical threshold. Similarly, chemical phase change reactions are harnessed to absorb excess heat, maintaining a stasis within the package without the need for external energy sources.

Advancements are not limited to the materials alone; design innovation plays a pivotal role as well. Computer-aided design (CAD) software facilitates the creation of packaging prototypes that optimize space and maximize insulation without increasing weight or volume unduly.

Increased connectivity through the Internet of Things (IoT) has also introduced smart heat barrier packaging solutions. Embedded sensors within the packaging can track temperature variations and, in some cases, adjust the internal temperature autonomously or alert users to potential risk.

As technology evolves, so does the potential for creating more effective, efficient, and environmentally friendly heat barrier packaging solutions that meet the complex and varying needs of different industries.

Conclusion: Ensuring Safety and Quality with Heat-Resistant Packaging

In conclusion, the development and implementation of heat-resistant packaging are critical for ensuring the safety and quality of temperature-sensitive products. The array of challenges presented by high-temperature conditions demands solutions that combine innovative materials, smart design, and strategic planning.

Today's market offers a myriad of advanced packaging options, from basic thermal insulation materials to high-tech active systems, capable of safeguarding products against the risks associated with extreme temperatures. These solutions are not just about protection; they also represent a commitment to maintaining the integrity and efficacy of the products we rely on in our daily lives.

As we look forward, it is clear that the packaging industry will continue to evolve, driven by technological advancements and an increasing focus on sustainability. The goal is not only to meet the present demands for heat-resistant packaging but to anticipate future challenges and meet them with equal innovation.

Staying informed about the latest developments and adhering to best practices will be key for businesses in ensuring that their products remain protected, no matter what thermal obstacles they may face. Heat-resistant packaging stands as a testament to the industry's ability to adapt and innovate, ensuring that quality and safety are never compromised.

Top Five FAQs on Thermal Protection Packaging Strategies

What are the key considerations for selecting high-temperature packaging materials?

Key considerations include thermal stability to endure specific temperature ranges, material compatibility with the product, cost-effectiveness, regulatory compliance, and environmental sustainability of the packaging materials.

How do thermal packaging materials ensure product safety during transit?

Thermal packaging materials maintain a stable internal temperature to protect sensitive products from external heat sources and fluctuations. This is achieved through insulating materials, reflective barriers, and possibly phase change materials that absorb or release heat as needed.

What are the advantages of utilizing smart packaging technologies in thermal protection?

Smart packaging technologies offer real-time tracking and monitoring of temperature conditions, ensuring immediate intervention when products are exposed to unsafe temperatures. This enhances the product's integrity and allows for data-driven decision-making throughout the supply chain.

Can sustainable materials provide adequate heat resistance in packaging?

Yes, advancements in sustainable materials have led to the development of bio-based and biodegradable composites that offer sufficient heat resistance, allowing companies to balance environmental responsibilities with the need for thermal protection.

What challenges are associated with designing packaging for high-temperature applications?

Design challenges include ensuring material performance under continuous high temperature, balancing cost with efficiency, preventing chemical reactions between packaging and product, and adhering to industry-specific regulatory requirements while considering sustainability and ecological impact.