Understanding the Role of a Packaging Technician

Stepping into the realm of packaging operations, one encounters the pivotal role of a packaging technician. These professionals are key players in the seamless delivery of products to consumers, ensuring that items are safely, efficiently, and effectively enclosed in suitable materials. The core of a packaging technician's job revolves around operating machinery designed to package products.

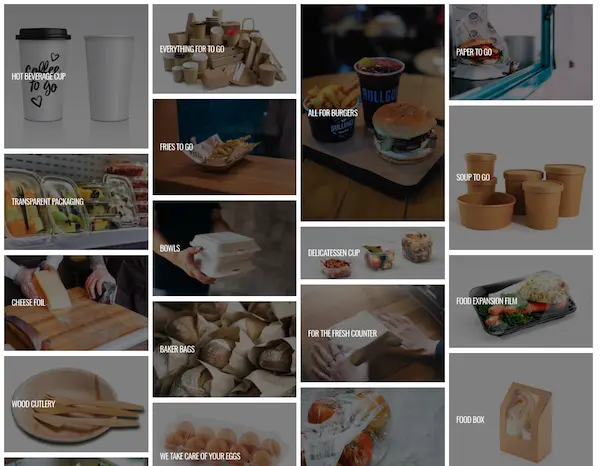

Moreover, the role is not just about wrapping and shipping; it involves a thorough understanding of various packaging materials and methods. A packaging technician must select appropriate solutions that best protect the product during transport while considering cost-effectiveness and sustainability. Additionally, they must be agile, adapting to different packaging designs and configurations depending on the item and industry requirements.

With our network with packaging suppliers along with a huge international network, we provide customizable logistic packaging services as per the needs and requirements of our clients, in order to maintain continuous product development and greatly reduce the spending for packaging solutions.

Safety is a top priority for a packaging technician, as they must often navigate the hazards of a fast-paced and mechanically intensive work environment. Consistent adherence to safety protocols and regulations is essential to prevent accidents and ensure a secure workplace. Furthermore, they play a crucial role in maintaining the quality of the product through vigilance in their packaging practices.

Consistent accuracy and attention to detail are hallmarks of a competent packaging technician. They monitor and adjust the packaging process, conducting regular inspections to validate that the output meets the established standards of quality. The meticulous nature of this work cannot be understated, as it directly impacts the customer experience and, ultimately, the reputation of the product and brand.

Essential Skills for a Successful Packaging Technician

To thrive as a packaging technician, one must cultivate a diverse set of skills. Proficiency in basic math is indispensable for calculating dimensions, quantities, and production specifications. This mathematical ability ensures precision when measuring packaging materials and scaling operations to different production volumes.

A packaging technician also needs to be well-versed in the principles of Good Manufacturing Practices (GMP). Understanding these regulations guarantees that the packaging process adheres to industry standards of quality and cleanliness, which are crucial in maintaining the integrity of the products, especially in the food and pharmaceutical sectors.

The technical skills cannot overshadow the importance of analytical abilities. Successful packaging technicians analyze issues that arise during the packaging process and apply their critical thinking to troubleshoot effectively. This technical acumen is particularly important when operating and performing preventative maintenance on complex machinery. A proactive approach to maintenance minimizes downtime and prolongs the lifespan of packaging equipment.

In our digital age, mastering data entry and basic computer skills is equally essential. Maintaining accurate records of production data, inventory levels, and quality control measures is often digitized, requiring packaging technicians to handle software applications pertinent to the packaging industry.

Lastly, teamwork and communication should not be underestimated. Packaging technicians often work within larger teams where collaborative effort and clear interchange of information are keys to a seamless operation. Whether it's partnering with peers on a production line or translating technical information to other departments, strong communication skills are vital in fostering a productive and harmonious workplace.

Assessing the Pros and Cons of Being a Packaging Technician

| Pros | Cons |

|---|---|

| Essential role in the supply chain | Potentially monotonous tasks |

| Opportunities for employment in various industries | Physical demands can be strenuous |

| Possibility for overtime and additional pay | Exposure to repetitive motion injuries |

| Requires minimal education or experience to start | Limited career progression without further education |

| Can lead to specialized roles with more responsibility | Work environment may be noisy and stressful |

| Training provided on the job | Shift work may be required, disrupting work-life balance |

Daily Duties and Responsibilities in Packaging Operations

The daily grind for a packaging technician involves a variety of tasks that are essential to the smooth running of packaging operations. A typical day includes initiating and managing the packaging process, from setup to completion. This involves operating and calibrating packaging machinery, ensuring that it functions correctly to avoid malfunctions or product damage.

An integral part of their routine is to regularly conduct quality control checks. These assessments are critical in detecting any defects or inconsistencies in packaging, allowing for immediate correction and averting potential product recalls or customer dissatisfaction.

Keeping the workspace clean and organized is more than a matter of tidiness; it's about maintaining hygiene and order in compliance with industry standards, especially in sectors like food and pharmaceuticals where contamination can have significant repercussions. This obligation also extends to the proper management of packaging materials inventory to prevent shortages that could lead to production delays.

Documentation is another cornerstone of a packaging technician's responsibilities. Accurate record-keeping tracks production outputs, quality control results, and machinery maintenance schedules. These records are not only a reflection of good practices but also serve as a compliance necessity and a reference for process improvement.

Effective communication plays a dual role in the technician's day-to-day activities. They must both interpret and follow detailed instructions for packaging procedures and also relay important information or report issues to their supervisors or team members. This ensures that any potential problem can be swiftly managed and that continuous process optimization is possible through collective input.

The Importance of Packaging Technicians in Product Safety and Compliance

Packaging technicians play a crucial role in safeguarding both the consumer and the company. They are the unsung heroes who ensure that every product that hits the shelf is not only visually appealing but also complies with stringent safety standards. Their attention to detail directly influences the product’s protection against contamination, damage, and tampering.

Compliance with regulatory agencies is non-negotiable in the packaging industry. Technicians are charged with the task of mastering and applying a myriad of regulations, such as the Food and Drug Administration (FDA) guidelines in the United States, which oversee the safety of food and pharmaceuticals. It's their expertise that keeps companies aligned with legal standards, avoiding costly recalls or legal actions.

Engaging with the latest techniques and materials in packaging is also part of a technician’s role in ensuring safety and compliance. They must be adept at selecting the appropriate packaging that can reliably preserve the product based on scientific understanding. With products ranging from perishable goods to fragile electronics, the choice of packaging can have considerable implications for product quality and shelf-life.

Furthermore, environmental considerations are increasingly paramount. Packaging technicians are expected to balance product protection with ecological responsibility, contributing to the development and implementation of eco-friendly packaging options that minimize waste and reduce the carbon footprint.

Educational Pathways and Certifications for Aspiring Packaging Technicians

For those eyeing a career as a packaging technician, educational groundwork and professional certifications can significantly enhance prospects. While some positions may offer on-the-job training, formal education bolsters foundational knowledge and technical prowess.

Prospective technicians often start with a high school diploma or equivalent, followed by vocational training or an associate degree in a field related to packaging technology or manufacturing. Courses in this pathway cover subjects such as machinery operation, packaging materials science, and industry-specific regulations.

Beyond basic education, certifications add a layer of professional credibility. The Certified Packaging Professional (CPP) designation, offered by the Institute of Packaging Professionals (IoPP), is a sought-after credential that validates an individual's expertise in packaging principles and practices. This certification requires passing an examination and, in some cases, accumulating a certain amount of professional experience.

Further specialization can be achieved through targeted certifications in areas like sustainable packaging, quality control, or advanced machinery operation. Such credentials demonstrate a commitment to continuous learning and a mastery of the challenges present in an evolving packaging landscape.

Other education options might include seminars, workshops, and continuing education courses that keep technicians updated on the latest innovations and compliance issues in the packaging industry. These learning opportunities are essential in a field where technology and regulations are constantly advancing.

Career Advancement Opportunities for Packaging Technicians

The career trajectory for a packaging technician doesn't have to end at the production line. With ambition and dedication, there are ample paths for growth and advancement. As they gain experience, technicians may advance to supervisory roles, managing teams and overseeing operations within their department.

Those with a keen eye for design and innovation can transition into packaging engineering positions. Here, they contribute to the development of new packaging solutions, improving efficiency, cost-effectiveness, and environmental sustainability. These roles may require additional education, such as a bachelor’s degree in packaging science or engineering.

Continued education and specialization also open doors to roles in quality assurance and project management. A packaging technician with substantial experience and advanced certification might become a quality assurance manager, ensuring products meet all standards and regulations before they reach consumers.

For those interested in the business and sales side of packaging, opportunities exist in account management and client relations. Packaging technicians with a solid technical background coupled with communication skills can thrive in these areas, acting as the nexus between the technical team and customers.

In conclusion, the world of packaging offers a dynamic range of career advancement opportunities. Whether through leadership, specialization, or cross-functional roles, packaging technicians have the potential to significantly impact the industry and their own professional development.

The Impact of Technology on the Packaging Industry and Technicians' Roles

The advent of cutting-edge technology has revolutionized the packaging industry, bringing about sweeping changes to the roles and responsibilities of packaging technicians. The integration of automation and robotics has transformed packaging lines, necessitating that technicians be adept at navigating sophisticated machinery and control systems.

Technological advancements such as 3D printing have opened new avenues for packaging prototyping and production, enabling technicians to experiment with complex designs and materials that were previously unattainable. Mastery of these innovative tools can set a packaging technician apart as a valuable asset to employers and forward-thinking companies.

Smart packaging technologies, which incorporate elements such as QR codes, NFC, and IoT sensors, require a new level of digital literacy from technicians. Understanding these technologies is crucial for technicians to monitor and ensure interactive packaging elements function as intended, further bridging the gap between the physical product and the digital experience.

In this landscape, continuous professional development is necessary for technicians to stay relevant. Keeping abreast of the latest technological trends allows packaging technicians to not only perform their roles efficiently but also to contribute to the evolution and innovation within the industry.

Key Challenges Faced by Packaging Technicians and How to Overcome Them

Packaging technicians encounter a variety of challenges in their careers, ranging from technical difficulties to environmental concerns. One of the primary hurdles is staying up-to-date with rapidly changing technology and machinery. To overcome this, ongoing education and training are paramount, enabling technicians to remain proficient in the latest advancements.

Another significant challenge is maintaining quality amidst the pressure to increase production speed. Technicians can address this by implementing lean manufacturing practices that streamline processes and by utilizing quality management systems to monitor and control quality standards more effectively.

Technicians also grapple with ensuring sustainable practices are applied in packaging, which is growing in importance to consumers and regulators alike. Embracing eco-friendly materials and processes can mitigate this concern, alongside continuing education about sustainable innovations in the field.

Communication barriers within teams and across departments can hamper efficiency. Fostering an environment of open dialogue and clear communication protocols can significantly enhance team collaboration and problem-solving capabilities.

In addressing these challenges head-on, packaging technicians can not only improve their own performance but also drive the industry forward, creating solutions that have a positive impact on their companies and the environment.

Industry Sectors Where Packaging Technicians Are in High Demand

In the diverse landscape of modern commerce, packaging technicians are vital in several key sectors. The food and beverage industry relies on these professionals to help preserve the freshness and extend the shelf-life of products while ensuring consumer safety and meeting regulatory standards.

The pharmaceutical sector demands a high level of expertise from packaging technicians, as medication safety, integrity, and proper labeling are of utmost importance. Strict adherence to hygiene and precise execution of packaging practices are crucial in this field.

With the rapid expansion of e-commerce, the need for robust and innovative packaging solutions has grown. Packaging technicians in the retail and distribution sector are instrumental in designing and executing packaging that withstands shipping while also being cost-effective and environmentally conscious.

The cosmetics and personal care industry presents unique challenges where the fusion of aesthetic appeal, product protection, and sustainability can be demanding. Technicians in this sector must balance these elements meticulously.

Moreover, the electronics industry requires specialized packaging to protect sensitive products from static and shock damage. Technicians working in this sector must be familiar with the advanced materials and techniques that ensure these items are delivered in perfect condition.

As these sectors continue to grow and evolve, the demand for skilled packaging technicians is likely to increase, offering a promising career outlook for those interested in joining this dynamic field.

Salary Expectations and Job Outlook for Packaging Technicians

The compensation for a packaging technician can vary, influenced by factors such as geographic location, industry sector, level of experience, and educational background. On average, packaging technicians can expect to earn a competitive salary that is commensurate with their technical skills and the complexity of their responsibilities in the packaging process.

Regarding the job outlook, the demand for skilled packaging technicians is robust and expected to maintain a steady climb. This growth is fueled by the continuous need for efficient, innovative, and sustainable packaging across various industries, coupled with the rising awareness of the importance of product packaging in marketing and product safety.

Opportunities for employment are broad, spanning small businesses to large multinational corporations. Job stability tends to be higher in sectors where packaging plays a critical role, such as in pharmaceuticals, food, and beverages. The rise of automation may shift the demand towards technicians with advanced technical competencies, highlighting the value of continuous skill development in this career path.

Overall, the role of a packaging technician is promising in terms of both salary potential and long-term career prospects, particularly for those who are willing to adapt and grow alongside technological advancements and industry changes.

How to Excel as a Packaging Technician: Tips and Best Practices

Excelling as a packaging technician demands more than just showing up for work. It involves a proactive approach to professional development and a thorough understanding of the field's best practices. Staying current with the latest packaging technologies and methods is critical. This may involve seeking out additional training sessions, conferences, and seminars that focus on emerging trends and innovations in the packaging industry.

Another tip for success is to fine-tune your problem-solving skills. In a role where unexpected issues can arise, being able to quickly and efficiently find solutions is invaluable. This often goes hand in hand with developing a strong attention to detail, which is essential for spotting potential problems before they escalate.

Effective time management is another pillar for those looking to excel. Packaging technicians must balance speed with accuracy, managing their time to meet production targets while maintaining high-quality standards.

Communication and teamwork are also paramount. As part of a larger team, you should aim to build a collaborative environment where ideas and strategies can be shared openly, fostering innovation and efficiency.

Implementing lean practices, focusing on waste reduction, and continuous process improvement in your day-to-day work can lead to significant enhancements in productivity and cost-effectiveness.

By adhering to these tips and best practices, a packaging technician can not only improve their daily performance but also position themselves for career progression within the industry.

Packaging Technician Success Stories: Real-life Examples

Throughout the packaging industry, there are numerous technicians whose careers have blossomed into success stories, serving as inspiration for others in the field. These individuals often started with a foundational interest in mechanical systems and a keen eye for detail, and through dedication and skill development, they have risen to prominent positions within their companies.

One such example is a technician who began their career on the production floor, operating machinery and learning the nuances of various packaging systems. With a commitment to ongoing education and an innovative mindset, they were able to spearhead a new environmentally friendly packaging initiative, resulting in significant cost savings and an industry award for their company.

Another success tale involves a packaging technician who excelled in quality control. By meticulously documenting production issues and collaborating with the engineering team, they were instrumental in redesigning a packaging line, ultimately enhancing efficiency and reducing waste. Their problem-solving prowess led to a promotion to a quality assurance management role.

These stories underscore that with the right mix of expertise, innovation, and collaboration, a career as a packaging technician can be highly rewarding and offer avenues for significant professional achievements.

Conclusion: The Future of Packaging and the Evolving Role of Technicians

The packaging industry is poised for continuous evolution, shaped by technological innovation, sustainability demands, and regulatory changes. Packaging technicians will inevitably see their roles adapt in response to these transformations. As packaging becomes more sophisticated, technicians will become even more integral, blending technical skills with strategic thinking.

The future will likely see a greater emphasis on automation and robotics, but the human element will remain crucial for oversight, maintenance, and quality assurance. Technicians with the foresight to embrace and master these changes will find themselves at the forefront of the industry.

Sustainability efforts will further drive the need for creativity in packaging design and materials, calling on technicians to be knowledgeable about eco-friendly options and waste-reduction techniques. The role of the packaging technician is not just about maintaining standards but also about driving progress, pushing the boundaries of what's possible in packaging, and ultimately influencing the environmental footprint of the industry.

In summary, the future for packaging technicians is bright and filled with opportunities for those willing to stay adaptable and invest in their skillset. The packaging technician's journey is one of lifelong learning, with each step offering the chance to shape the industry's trajectory toward a smarter and more sustainable future.

Packaging Technician: Key Insights and FAQs

What is the primary responsibility of a packaging technician?

A packaging technician is responsible for operating machinery that packages products, ensuring they are safely and efficiently enclosed in suitable materials for transport while adhering to safety protocols, regulations, and quality standards.

Which skills are essential for a successful packaging technician?

Essential skills include proficiency in basic math for calculating specifications, understanding of Good Manufacturing Practices (GMP), analytical abilities for troubleshooting, as well as computer literacy for data entry and record-keeping.

What kind of educational background is required for a packaging technician?

Typically, a high school diploma or equivalent is required, with vocational training or an associate degree in packaging technology or manufacturing being beneficial. Certifications such as the Certified Packaging Professional (CPP) can also enhance career prospects.

Are there opportunities for advancement as a packaging technician?

Yes, there are numerous paths for growth and advancement, including supervisory roles, packaging engineering, quality assurance, and project management. Continuous education and specialization are key for advancing in a packaging career.

How has technology impacted the role of packaging technicians?

Technology has led to the integration of automation, robotics, and smart packaging technologies, necessitating technicians to possess advanced technical skills, digital literacy, and a commitment to continuous professional development.