- Initial design reviews ensure the packaging meets all specifications and standards before production.

- Regular inspections during manufacturing check for defects and adherence to quality control protocols.

- Final audits of the packaged products verify compliance with customer requirements and safety regulations.

Hey there everyone! I was just wondering, could someone shed some light on the quality assurance process for the packaging production? I have been curious about this for a while, and I believe it would be helpful to know how it works, especially for those of us who are passionate about fashion. Do we have any procedures in place? Is there some kind of quality control team? Also, if anyone has ever worked on this process, or knows someone who has, I would love to hear your personal experience and opinions on it! Thanks in advance!

Hello fashion lovers! As a history buff, I find the manufacturing processes behind clothing and accessories fascinating. Quality assurance is such an important part of production, especially when it comes to packaging.

To answer your question, FashionForward606, yes, there are usually procedures in place when it comes to quality control in packaging production. From my personal experience, the process usually involves a team of professionals who thoroughly inspect the packaging to ensure it is up to standard and meets the requirements of the brand. They check for anything from visual aspects, such as the design, to practical aspects, like durability and functionality.

I think it's great that you're interested in this aspect of fashion. It's important to remember that packaging is a reflection of the brand and can affect customer satisfaction. I've never personally worked on the process myself, but I have seen firsthand the benefits of having a thorough quality control team. It can save time and resources in the long run, as it helps to avoid costly mistakes and unhappy customers.

Overall, I think it's essential for anyone who is passionate about fashion to understand the production process and the importance of quality control. It not only improves the brand's reputation, but it's also a mark of professionalism.

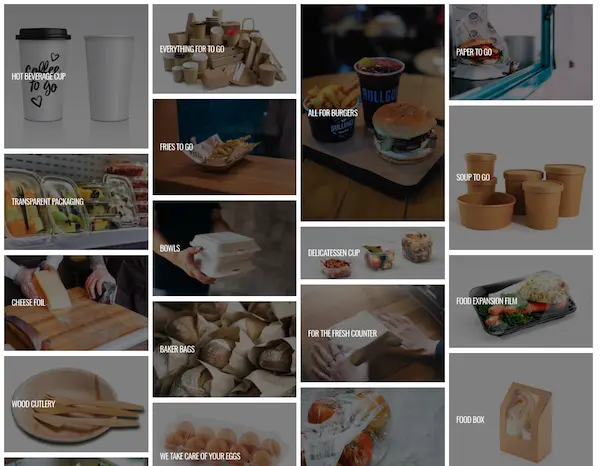

With our network with packaging suppliers along with a huge international network, we provide customizable logistic packaging services as per the needs and requirements of our clients, in order to maintain continuous product development and greatly reduce the spending for packaging solutions.

Hey FashionForward606,

I completely agree with HistoryBuff505 on quality assurance being such an important part of production, especially when it comes to packaging. It's great that you want to know more about the process because the packaging is an essential aspect of any fashion brand.

From my experience, the quality control team usually consists of professionals who have a keen eye for detail, and they thoroughly examine the packaging to ensure that it meets the standards of the brand. They check everything, from the design to its functionality and durability.

In my opinion, having a proper quality control team can make a big difference as it ensures that all the packaging is flawless and represents the brand well. I have always found that the better the packaging, the more likely I am to recommend it to others or even become a repeat customer.

As HistoryBuff505 mentioned earlier, packaging is a reflection of the brand. So, it's critical to put in place a thorough quality assurance process, which plays a substantial role in improving the brand's reputation and increasing overall customer satisfaction.

Overall, it's awesome to see people interested in the behind-the-scenes aspects of fashion. I strongly believe that having an understanding of the production process, including the quality assurance process for packaging, can serve as a mark of professionalism. If anyone else has worked on this process, I would love to learn more about your personal experiences and opinions.

Cheers!

Hey FashionForward606 and all the fashion enthusiasts out there,

It's great to see so much interest in the quality assurance process for packaging production. As a passionate member of the community, I completely agree with HistoryBuff505 and CodeCracker23 that quality control is essential to the process.

From my experience, the quality control team consists of professionals who have a sharp eye for detail and go through extensive measures to ensure the packaging meets the brand's standard. The team checks everything from design to durability and functionality, making sure that it's up to par before being released to the market.

In my opinion, having a proper quality control team can indeed make a massive difference in how the brand is perceived. Good packaging reflects a professional, well-thought-out brand and contributes immensely to customer satisfaction. I have found that the better the packaging, the more likely I am to recommend the brand to others or even become a repeat customer.

It's always great to get behind the scenes and learn more about how the production process works. I believe that understanding the quality assurance process in packaging production can help us gain a greater appreciation for the brand, products and fashion industry as a whole.

So if any of you have worked on this process, or has anything interesting to share about it, feel free to share your views. I'm always on the lookout to learn more and engage with fellow fashion enthusiasts.

Cheers!

Hello there, FashionForward606 and fellow fashion enthusiasts,

I am thrilled to see so many people interested in the quality assurance process of packaging production. As a passionate member of the community and a lover of all things fashion, I completely agree with the sentiments expressed by my fellow forum members, HistoryBuff505 and CodeCracker23.

Based on my experience, the quality control team is made up of professionals who have a sharp eye for detail and go to great lengths to ensure that the packaging meets the brand's standards. They check everything, from the design to the durability and functionality, leaving no stone unturned.

In my opinion, having a proper quality control team is absolutely essential in ensuring that the brand is perceived as professional and well thought out. Good packaging reflects this, and it contributes immensely to customer satisfaction. In fact, I have found that the better the packaging, the more likely I am to recommend the brand to others or even become a repeat customer.

It is always fascinating to have a behind-the-scenes look and learn more about how the production process works. I believe that understanding the quality assurance process in packaging production can help us gain a greater appreciation for the brand, products, and the fashion industry as a whole.

So, if any of you have worked on this process or have anything interesting to share about it, feel free to share your experiences and opinions. As for me, I look forward to engaging with more of you and learning about your thoughts on this topic.

Cheers to the fashionable life!

Greetings fellow fashion enthusiasts,

I want to take a moment to thank everyone who has contributed to this discussion on the quality assurance process for packaging production in the fashion industry. Your insights and personal experiences have been invaluable in shedding light on this important aspect of the production process.

As we have learned from our forum members, the quality control team is an essential part of ensuring that packaging meets the brand's standards. From design to durability, the team leaves no stone unturned in making sure that everything is up to par before being released to the market. Good packaging is a reflection of a professional brand and contributes immensely to customer satisfaction, which is crucial in today's competitive market.

I appreciate hearing from those who have worked on this process and have seen firsthand the benefits of having a thorough quality control team in place. Your personal experiences and opinions have added a lot of depth to this conversation and have given us a better understanding of the considerations that go into packaging production.

Overall, I think it's important for anyone who is passionate about fashion to understand the production process and the role that quality assurance plays in ensuring a successful customer experience. It's great to come together as a community to share our thoughts and learn from each other.

Once again, thanks to all who have contributed their ideas to this discussion. I look forward to engaging with more of you and learning about your perspectives on this and other fashion-related topics.

Cheers to the fashionable life!

Hey folks,

Loving this conversation about quality assurance in packaging, and I think it's absolutely crucial to have this on our radar. Now what I'd add to the dialogue is the importance of incorporating sustainability practices into this process.

The fashion industry is under increasing scrutiny for its environmental impact, and packaging is indeed a part of that conversation.

So, when looking at quality assurance, it's key to consider the materials being used, whether they're recyclable or compostable, and how they're produced. We should also keep in mind if there's a plan for transport that minimizes the carbon footprint.

And it's not just about appealing to the environmentally-conscious consumer or meeting regulatory standards - it can also increase efficiency and save costs in the long run.

Consider this: a reusable bag can not only cut down on the number of single-use packaging materials a company uses, but it can also serve as free advertising if it’s designed with your logo or brand name.

It’s definitely something for any fashion brand, or anyone passionate about fashion, to think about. The packaging isn't just securing the product on the way to customers; it's also communicating brand values.

Just my two cents. Would love to hear anyone else's thoughts on this!

Sure thing, I also feel it's engaging to consider how quality assurance can be made more innovative and effective using technology. For example, computer-aided designs and virtual reality can help simulate packaging and run tests before any material is even produced, hence reducing waste and increasing efficiency.

Well, I hate to be the party pooper here, but I've had quite a few negative experiences with quality assurance in packaging. It's not always as smooth nor as effective as we'd hope for. Without going into specifics, I've seen products in shoddy packaging that didn't meet basic standards, ruining the allure of the product. More attention definitely needs to be paid to this area.

Absolutely, and let’s not forget that quality assurance doesn't stop once the packaging gets approved. It’s an ongoing process that evaluates the consistency of the packaging to the predetermined quality standards over time. This might also include changes in supplier management, material selection, or even changes in company policy. Quality assurance should be seen as a holistic, evolving process, not a simple checkbox. Regularly checking on these processes helps a brand to maintain its credibility, which is absolutely vital in the crowded retail space we're dealing with today. Moreover, neglecting quality assurance can create waste, degrade customer loyalty, and eventually erode brand value.

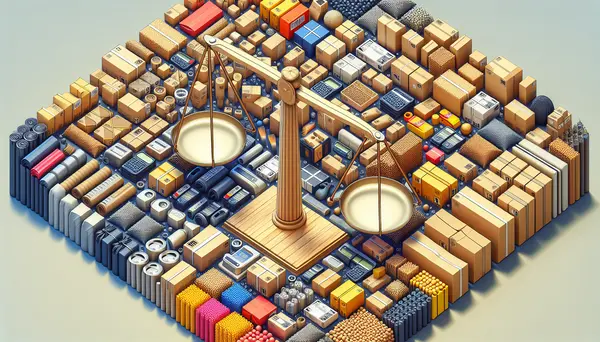

Without a doubt, everything that’s been mentioned so far makes a lot of sense. I am wondering, however, how can a brand strike a balance between maintaining high-quality Packaging standards and the cost involved? Packaging may represent a significant expense in the overall product budget. How can brands ensure they're not compromising the quality of their packaging, yet still keep costs manageable? Even more so, how can smaller brands or newer businesses that don’t have significant capital to invest ensure quality in their packaging? I’d love to hear your thoughts on this!

Well, you know what they say, a good package is like a joke... if it needs explaining, it's no good!

I must say, I have found that most brands, regardless of their size, still fall short when it comes to packaging quality and design. It's a pity because it can drastically affect the overall customer experience.

Just dropping in to say I've seen packaging so well done, it's like trying to get into a bank vault. Now that's secure! But jokes aside, remember the trip to the recycling bin is a lot shorter than the trip back to the store for a refund. Getting the balance right is key! And may the odds always be in your favour when wrestling your next package!

Great points everyone - it\'s definitely a balancing act. Ensuring quality while taking into account cost, sustainability, and customer experience is indeed a tall order, but it\'s a worthy challenge to tackle. After all, providing customers with the best experience possible should always be at the forefront of a brand\'s strategy.

Oh, the joys of package quality assurance, where every seal, flap, and sticker is a potential game of "Will it open or will it explode?" But seriously, it's like a backstage ballet where every material and process must pirouette with precision. A poorly chosen adhesive here, a too-tight ribbon there, and voila, your customer's unboxing video goes viral for all the wrong reasons. Let's not forget those fun little "easy-open" tabs that require the jaws of life to part. High-quality packaging is a symphony played by a harmonious orchestra of designers, engineers, and machines, each with their own part to play in creating a masterpiece that gets your shiny product to your customer's doorstep without looking like it's been through a toddler's birthday party.

Turning that packaging fiasco into a smooth ride— definitely a work of art. It's all about marrying form and function without playing Jenga with your budget.

- How do changing consumer behaviors, like the move to online shopping, impact packaging needs? 3

- How do packaging designs address the growing trend of DIY kits or self-assembly products? 4

- What are some alternative packaging solutions you've seen in the automotive industry that impressed you? 12

- How do different lighting conditions (e.g., store lights vs. daylight) affect packaging appearance? 5

- What are your thoughts on the environmental impact of paper alternative coffee cups? 8

- How do packaging designs cater to the growing trend of experiential or hands-on learning products? 1

- How are companies using packaging to enhance the educational or informative aspects of products? 5

- Do you prefer bread that is packaged in paper bags with windows, or does the packaging not affect your purchase decision? 11

- What's the impact of oversized packaging on waste and the environment? 4

- Have you implemented any innovative solutions to reduce waste in your internal packaging? 13

- What are the challenges of using biodegradable materials in packaging? 380

- What are the latest technological advancements in packaging machinery? 305

- What are some challenges you have faced with automotive packaging, and how did you overcome them? 291

- Are there any concerns regarding the food safety or longevity of bread stored in paper bags with windows? 288

- How would you improve the current design of paper shopping bags to make them more user-friendly or sustainable? 285

- What's the process for quality assurance in our packaging production? 283

- Can you share some tips on how to reduce the use of consumable materials? 281

- Have you encountered any problems when using paper shopping bags in certain weather conditions? 279

- How does the feel and usability of HDPE bags compare to other materials such as paper or fabric? 273

- How do you balance the need for protection and efficiency in your internal packaging processes? 268

Blog Posts | Current

Efficient Solutions for Managing a Packaging Warehouse

Understanding the Basics of a Packaging WarehouseFirst things first, let's delve into the basics of a packaging warehouse. Essentially, a...

Navigating Packaging Regulation: Compliance and Industry Insights

Understanding Packaging Regulation: A Brief OverviewThe world of packaging regulation can be a complex maze to navigate. However, understanding these...

The Cornerstones of Effective Packaging Design: Key Rules to Consider

Introduction Packaging design is far more than a mere protective cover for a product. It is a potent communication tool that...

Becoming a Packaging Operator: Skills and Responsibilities

Introduction to the Role of a Packaging OperatorStarting a career in the packaging industry can be an exciting opportunity, especially...

Effective Strategies to Minimize Packaging Waste

Understanding the Importance of Minimizing Packaging WasteIn an increasingly consumer-driven society, the growing problem of packaging waste cannot be ignored....

Sustainability in Packaging Design

Introduction As environmental concerns continue to gain prominence in public and corporate consciousness, the topic of sustainability in packaging design has...

Recycling in Packaging: A Sustainable Approach for a Greener Future

Introduction Packaging is an integral aspect of every product that we consume or use. However, the growth in consumerism and the...

Negotiated Price vs. Demand Quantities: A Detailed Examination

Price negotiation and demand quantities are two significant factors affecting both the supply and demand of goods in the market....

Industrial Packaging Production: A Cornerstone of Modern Manufacturing

Introduction Packaging is an indispensable part of any industry, providing a protective shield for products during their journey from the production...

Understanding Packaging HSN Codes

Introduction to Packaging HSN CodesWhen it comes to the realm of packaging, understanding the complexities and details can often be...