Understanding Packaging Hazards: An Overview

When we talk about packaging hazards, we refer to potential risks that can compromise the safety and integrity of a product during transportation and storage. These hazards can stem from a variety of factors, each playing a significant role in how we approach packaging design and materials selection. Understanding these risks is the first step in creating a packaging strategy that ensures products arrive at their destination in the same condition they left the factory.

Packaging hazards broadly fall into three main groups: physical, environmental, and human-related risks. Physical hazards are associated with damage from impact, pressure or piercing, while environmental hazards relate to climatic conditions like temperature fluctuations or moisture. Human-related risks include errors in handling or tampering. Identifying these risks often involves analyzing the entire supply chain to pinpoint where damage could occur.

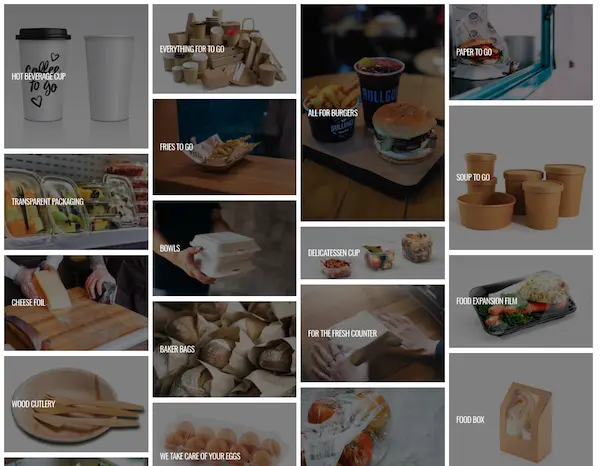

With our network with packaging suppliers along with a huge international network, we provide customizable logistic packaging services as per the needs and requirements of our clients, in order to maintain continuous product development and greatly reduce the spending for packaging solutions.

Properly addressing packaging hazards means more than just choosing strong materials; it requires a holistic approach to packaging design, considering everything from the shape and size of the packaging to the modes of transportation used. Only through careful consideration of all possible risks can a company adequately protect its products and minimize the likelihood of damage leading to customer dissatisfaction and financial loss.

By understanding the potential hazards that can affect your packaging, you are better equipped to select the right materials, design your packaging more effectively, and improve the overall safety of your product during its journey to the consumer.

The Four Main Categories of Shipping Hazards

The transportation journey introduces varied shipping hazards that can jeopardize packaged goods. To effectively mitigate these risks, it's important to first categorize them. This categorization aids in pinpointing specific challenges and developing tailored protection strategies for each type of hazard. The four main categories are critical in understanding the full scope of potential risks in shipping and logistics.

The primary concern is shock damage, caused by sudden impacts or drops that can occur during handling and transit. The severity of shock damage can range from minor dents to catastrophic breaks, particularly for fragile items. Managing this hazard requires carefully engineered cushioning and robust packaging design to absorb and distribute energy.

Next, vibrations pose a persistent threat, often resulting from the engine, road surface, or movement of the transport vehicle itself. Continuous shaking can lead to abrasion, loosening of parts, and even structural failure over time. To counteract vibration hazards, packaging solutions incorporate stabilizing materials and securement techniques that hold the product firmly in place.

Compression hazards arise when packages are stacked or subjected to heavy loads, pressing down on the items within. Overlooking this can lead to crushed packaging and damaged contents, especially when the distribution process involves long storage periods under weight. Crafting packaging with sufficient load-bearing capacity is essential for withstanding these compressive forces.

Last but not least, atmospheric hazards such as temperature changes and humidity can impact product integrity. These conditions may cause materials to expand or contract, encourage condensation, or lead to other forms of moisture damage. Protective measures, including climate-controlled environments and moisture barriers, alleviate the adverse effects of these atmospheric challenges.

By breaking down the discussion of packaging hazards into these categories, stakeholders can develop strategic approaches to packaging that addresses each risk comprehensively, ensuring a higher level of product safety through the shipping process.

Shock Hazards in Packaging: Causes and Prevention

Shock hazards are a common concern when it comes to the integrity of packaging during transit. These incidents are characterized by sudden impacts that can occur as packages are loaded and unloaded, or if they fall during handling. The type and severity of shock that can cause damage are dependent on various factors, including the height of a drop, the angle of impact, and the nature of the product inside the packaging.

| Cause of Shock | Typical Prevention Methods |

|---|---|

| Drops during handling | Use of cushioning materials, drop-testing packaging designs |

| Impacts from collisions | Sturdy exterior packaging, secure closure systems |

| Rough transportation | Shock-absorbing pallets, freight stabilization |

To prevent damage from shock hazards, packaging engineers employ drop tests as a standard part of the design process. These tests help determine at what height and under what conditions the packaging may fail, allowing for design modifications to improve resilience. Additionally, the use of protective padding and shock indicators inside the package can alert handlers to sensitive contents and signal if an excessive impact has occurred.

The choice of materials is also significant in preventing shock damage. For instance, the incorporation of impact-resistant polymers or the layering of corrugated materials can remarkably improve the ability of packaging to withstand rough treatment. Moreover, proper labeling plays a critical role, instructing handlers on the fragility of the contents and the need for careful handling.

While completely eliminating shock hazards may not be possible, implementing these preventative measures can drastically reduce the potential for damage, maintaining the safety and integrity of the packaged goods.

Vibration and Its Impact on Packaging Integrity

Vibration can subtly yet significantly compromise packaging integrity. During transportation, consistent movement, especially in vehicles like trucks, trains, or airplanes, creates an environment where vibration is inevitable. The repetitive motion can weaken packaging materials, dislodge components, and even cause friction that leads to wear and tear on the product.

Special consideration must be given to the nature of the vibrations. The frequency and amplitude of these movements are important factors that determine potential damage. For example, low-frequency vibrations may cause a slow but constant shaking that affects differently than high-frequency vibrations, which might result in a more rapid and jarring effect.

- Secure Packaging: Reinforcing packaging with straps and void fillers can immobilize products, reducing the ability of vibrations to affect them.

- Material Selection: Choosing materials with higher durability and shock absorption properties can help mitigate the effects of vibration.

- Transportation Mode: Understanding the vibration characteristics of different transport methods can influence decisions on the best means of shipment.

Another preventive measure is to conduct vibration testing during the packaging design phase. This testing simulates the various frequencies and intensities of vibrations that the package will encounter in transit. By assessing the packaging's performance under such conditions, adjustments can be made to enhance robustness and protect the contents more effectively.

Lastly, ensuring that products are firmly positioned within the packaging without unnecessary room to move can be pivotal. Utilizing custom-fitted inserts or braces keeps items stable and can limit the damaging impact of vibration. While not all movement can be eliminated, strategic packaging design and material choice can greatly reduce vulnerability to vibration hazards.

The Risks of Compression on Packaged Goods

Compression poses a formidable risk to packaged goods, resulting from the stacking of heavy loads that exert force upon the products beneath. This pressure can distort packaging materials or even crush the contents within, especially when items are confined in a tight space such as a cargo container or delivery vehicle. Understanding and mitigating the risks of compression is crucial for maintaining product integrity during shipping and storage.

Factors contributing to compression risks include the weight of overlying items, the duration of the applied load, and the strength of the packaging materials themselves. To enhance compression resistance, it's essential to look at both the packing methodology and the innovations in packaging materials.

- Stacking Protocols: Establishing guidelines for safe stacking limits to prevent overloading packages.

- Box Design: Creating reinforced corrugated boxes or using double-wall designs for additional strength.

- Material Testing: Performing compression tests to assess the maximum load a package can bear without failing.

In addition to these measures, utilizing interlocking patterns when stacking can distribute the weight more evenly and reduce the strain on any single point of a package. The introduction of supportive elements, such as edge protectors or pallets designed for superior load-bearing, also plays a significant role in warding off compression damage.

Through a combination of thoughtful design, material selection, and careful handling processes, the risks associated with compression on packaged goods can be significantly reduced, ensuring that products reach their destinations in pristine condition.

Atmospheric Conditions: Protecting Against Temperature and Humidity

Atmospheric conditions present unique challenges in maintaining packaging integrity, where both temperature and humidity play pivotal roles. Fluctuations in these elements can lead to deterioration of packaging materials, condensation, and even compromise the quality of the product itself. Shielding against these environmental variables is a key aspect of a comprehensive packaging strategy.

To protect against extreme temperatures, products may require insulation or the use of temperature-controlled packaging. This is particularly crucial for goods like pharmaceuticals, food, and electronics that are sensitive to heat or cold. For instance, employing specialized liners, ice packs, or even advanced phase change materials can maintain a consistent temperature range.

- Barrier Materials: Use moisture-resistant coatings and films to prevent moisture transfer.

- Desiccants: Include materials within the packaging that absorb humidity to safeguard against moisture damage.

- Sealing Techniques: Apply seals that prevent the ingress of moisture while maintaining the product's climatic isolation.

When addressing the threat of humidity, it's vital to incorporate elements that actively combat the accumulation of moisture. Strategies like airtight packaging and the inclusion of desiccants can be highly effective in keeping humidity at bay and preventing the growth of mold or other contamination that could affect the product.

Lastly, considering the possible elevation changes during transport that could affect internal package pressure is essential. Specialized venting mechanisms can prevent the buildup of pressure and mitigate the risk of package rupture or seal failure.

With diligent attention to these preventative measures, products can be shielded from the often-overlooked risks posed by atmospheric conditions, ensuring they emerge from their transit unaffected by the rigors of their environment.

Designing the Ideal Package for Maximum Protection

Designing the ideal package demands a strategic approach that marries form with function, ensuring maximum protection while maintaining cost efficiency. This design process involves a blend of material science, engineering principles, and an understanding of the logistics involved in the product's journey. The goal is to construct packaging that not only prevents damage but also aligns with the product's specific needs and the end-user's expectations.

Key considerations in crafting such packaging include precise fit and containment. A package that securely encases its contents, tailored to the shape and size of the product, minimizes movement and the potential for damage. Utilizing custom-designed inserts or molded forms can stabilize items within the box, reducing the reliance on additional cushioning materials.

- Multi-Material Utilization: Combining various materials to leverage their collective strengths for enhanced protection.

- Modular Design: Creating adaptable packaging that can be easily scaled or adjusted to fit different product sizes or quantities.

- Usability Focus: Ensuring the package is user-friendly, making it easy to open and handle, reduces the risk of damage during the unboxing process.

Moreover, the durability of the packaging is paramount. By selecting high-quality materials that are tested for their resistance to stressors like impact, compression, and puncture risks, the package can endure the rigors of transportation with a lower likelihood of structural failure. Additionally, environmental considerations must be factored into the design process, choosing materials that best withstand variances in climate or that offer barrier properties against contaminants.

In conclusion, the process of designing the ideal package is intricate, requiring a balance between protective features and pragmatic considerations. A well-conceived package serves as a guardian of the product within, offering resilience against the myriad threats encountered from warehouse to the end user, all while aligning with sustainability goals and regulatory requirements.

Conventional Corrugated Boxes: A Safe Choice for Packaging

In the realm of packaging solutions, conventional corrugated boxes stand out for their reliability and protective qualities. These boxes are a commonplace yet effective option thanks to their versatile design, which can accommodate a wide range of product types and sizes. The corrugated structure itself, characterized by a fluted arched paper design sandwiched between two liners, provides a robust defense against many common packaging hazards.

The material's inherent rigidity and cushioning capabilities are key to its success in shielding contents from impacts and vibrations. The corrugated design also lends itself to stacking strength, an essential feature for goods that must be warehoused or transported stacked atop one another.

- Customization: Corrugated boxes can be manufactured to custom specifications, ensuring optimal fit and protection for any product.

- Recyclability: Made from paper fibers, corrugated boxes are easily recyclable, aligning with environmental sustainability efforts.

- Printability: The outer surfaces are amenable to high-quality printing, which can enhance branding or provide clear handling instructions.

For products that require additional security against atmospheric conditions, such as changes in humidity or temperature, corrugated boxes can be treated or combined with various coatings and liners. These enhancements extend the range of applications for which these boxes can be safely employed, safeguarding even sensitive items throughout the logistics chain.

Choosing conventional corrugated boxes for packaging is not just about safety; it's also a decision that supports sustainability and brand visibility. With the right structural design and material treatment, they maintain a trusted position as a go-to choice for businesses looking to combine protection with practicality.

Preventing Accidents: Packaging Design for Stability

When considering packaging strategies, ensuring stability throughout handling and transit is pivotal to preventing accidents. The design of the packaging must foster a secure environment for the product, negating risks such as tipping, rolling, or collapsing, which can lead to damage and, subsequently, increased costs and customer dissatisfaction.

Stability in packaging design incorporates a proactive approach, taking into account how the package will interact with external forces. This encompasses the weight distribution within the package, the shape and geometry of the packaging, and how these factors align with storage and transportation methods.

- Weight Distribution: Positioning heavier items at the bottom and evenly distributing the weight to maintain a low center of gravity.

- Structural Integrity: Reinforcing weak points and utilizing strong joining methods to ensure the package holds its shape under stress.

- Interlocking Components: Designing packages that can securely stack on top of one another, with features that interlock to prevent sliding or shifting.

Attention to the base of the packaging is equally important, as a broad and stable foundation can prevent many potential tip-overs. Materials used for packaging should be tested for slip resistance, ensuring that packages do not easily slide during transport, which could compromise the overall stability of the load.

The safety benefits derived from a stability-focused design philosophy are clear. Less risk of package failure means fewer accidents, less product loss, and a stronger reputation for reliable delivery. This proactive stance on packaging stability is essential for any business seeking to uphold the highest standards of product safety in their supply chain.

Tailoring Packaging to Product Fragility

Every product has a unique set of requirements when it comes to packaging, and this is particularly true for items that are fragile or delicate. Tailoring packaging to product fragility is essential to ensure that these items are adequately protected from the potential perils of the shipping process. A customized packaging solution takes into account the specific attributes and vulnerabilities of a product, crafting a protective cocoon that can withstand shocks, vibrations, and other hazards.

Consideration of the product's material composition, weight, shape, and size dictates the selection of packaging materials and the design of protective features. For exceptionally fragile items, the use of specialized cushioning materials — such as foam inserts, bubble wrap, or inflatable airbags — can provide the necessary shock absorption to buffer against impacts.

- Material Resilience: Selecting materials that offer a balance between flexibility and rigidity to cater to the needs of fragile products.

- Securement: Employing custom fittings that embrace the product, preventing movement within the package during transit.

- Layering: Implementing a layering strategy where the product is wrapped and then placed in a supportive outer shell for added protection.

For items that may be vulnerable to pressure or crushing forces, structural reinforcements can be introduced to improve the compression strength of the packaging. This might involve using thicker wall constructions or additional bracing supports at strategic positions within the box.

By meticulously crafting packaging to cater to the fragility of the product, businesses can minimize damage rates, enhance customer satisfaction, and preserve their reputation for delivering products in pristine condition. It's a nuanced approach that blends design, materials science, and a deep understanding of the product's needs to create an optimal packaging solution.

The Importance of Space and Cushioning in Packaging

The strategic use of space and cushioning is integral to designing effective packaging that can buffer and defend against the bumps and drops inherent to the shipping process. Proper utilization of these elements ensures that products are not only secure but also have the resilience needed to absorb external stresses without sustaining damage.

Space within a package acts as a buffer zone, distancing the product from potential impact zones such as the corners and edges of the box. This gap allows for the inclusion of cushioning materials that provide a shock absorbent layer, significantly reducing the force that reaches the product when subjected to impact.

- Choice of Cushioning: Assessing the most appropriate cushioning material based on the product's weight, dimensions, and fragility, whether it be foam inserts, air pillows, or corrugated buffers.

- Filler Materials: Using loose fill materials like packing peanuts or crumpled paper to fill voids and prevent shifting of the product within the package.

- Placement Strategy: Applying cushioning not just around the product, but also between multiple items in the same package to avoid contact damage.

Cushioning materials serve the dual purpose of protecting the product and maintaining its position within the package to prevent excessive movement. Options such as pre-molded end caps can be particularly effective for goods with exacting space tolerances, ensuring that the item remains immobile during transit.

In summary, carefully calibrated space and strategic cushioning are crucial components of a well-designed packaging system. They act synergistically to cushion products against the forces encountered during shipment, thereby enhancing the overall safety and integrity of the delivered goods.

Pre-Shipment Testing: Ensuring Packaging Safety

Before a product embarks on its journey to the end-user, it is critical to assess the packaging safety to ensure it can withstand the logistical rigors it will face. Pre-shipment testing is the process through which a packaging system is subjected to simulations that mimic the conditions of transport. This step helps to identify vulnerabilities in the packaging design and allows for corrections before any actual product damage can occur.

These tests are conducted using industry-standard protocols that replicate the stresses of handling, stacking, and transporting goods. Rigorous testing may include drop tests, vibration tests, compression tests, and assessments under various environmental conditions such as changes in temperature and humidity.

- Industry Standards: Adhering to established testing standards such as those from the International Safe Transit Association (ISTA) provides an objective measure of packaging performance.

- Simulation Accuracy: Ensuring that test simulations accurately reflect real-world scenarios, capturing a range of potential hazards that the package might encounter.

- Performance Analysis: Collecting data on how the packaging fares during tests to guide potential enhancements or the need for redesign.

Conducting pre-shipment tests presents an opportunity to refine packaging designs, select more suitable materials, and ensure proper cushioning placement. This preemptive approach is a vital part of a quality assurance process, building confidence in the packaging's ability to protect products until they safely reach their destination.

To conclude, pre-shipment testing is an essential stage in the packaging development process. It validates the safety and efficacy of packaging solutions, reducing the risk of product damage and loss, and ultimately ensuring customer satisfaction.

ISTA Test Procedure 3A: A Standard for Safe Packaging

The ISTA Test Procedure 3A is a recognized standard that provides a comprehensive framework to evaluate the resilience of packaging designs for single-parcel shipments weighing up to 150 pounds. This test ensures that packages can endure the typical handling and transportation stresses expected in parcel delivery systems.

Designed to challenge the packaging's ability to protect its contents against shocks, impacts, compression, and other challenges, the ISTA 3A procedure is a critical benchmark for businesses that wish to guarantee the safety of their packaged products. The test simulates real-world scenarios through a series of controlled laboratory experiments that mimic various stressors such as drops, horizontal impacts, vertical vibrations, and atmospheric conditioning.

- Test Sequence: Implementation of a predetermined sequence of tests that replicate real handling and shipping conditions.

- Documentation and Reporting: Comprehensive recording of test methods, conditions, and results to maintain a clear and consistent testing process.

- Continuous Improvement: Using test outcomes to make data-driven decisions for improving packaging integrity and performance.

Adherence to the ISTA Test Procedure 3A is seen as a proactive commitment to quality and safety. It demonstrates a company's dedication to delivering their products without damage, building trust with their customers and potentially reducing the costs associated with returned or damaged goods.

In summary, the ISTA 3A test procedure is an indispensable part of the packaging design process, providing the rigorous validation needed to ensure that packaging can reliably protect products in the challenging world of parcel delivery services.

Expert Insights: Contacting William I. Kipp for Packaging Safety Advice

For those seeking to deepen their understanding of packaging safety and to ensure their practices adhere to the highest standards, gaining expert insights is invaluable. William I. Kipp, a seasoned professional in the field, offers a wealth of knowledge derived from years of experience specializing in the science of safe transport for packaged goods.

Engaging with experts like Kipp can provide clarity and direction in developing packaging that is both durable and cost-effective. His advice can be particularly beneficial when navigating complex packaging challenges or when aiming to meet specific industry regulations and testing standards.

- Custom Consultations: Personalized advice tailored to the unique challenges of your product and packaging requirements.

- Resource Accessibility: Access to a rich library of materials, research findings, and case studies that can inform and influence packaging strategies.

- Training and Education: Opportunities for in-depth training sessions and workshops to upskill your team on the latest trends and technologies in packaging safety.

Reaching out to experts like William I. Kipp can transform a company's approach to packaging, embedding a culture of safety and continuous improvement within the organization. Such collaboration not only enhances the protective qualities of packaging but also streamlines processes and can lead to cost savings in the long term.

In conclusion, harnessing the insights of packaging safety experts is a strategic move that can pay dividends in ensuring the reliable delivery of products, bolstering a brand's reputation for quality and care in its consumer transactions.

Conclusion: Balancing Safety and Cost in Packaging Design

In the intricate dance of packaging design, the ultimate goal is to strike a harmonious balance between safety and cost. Achieving this equilibrium ensures that products are effectively protected from the myriad of potential hazards they encounter while also considering the economic reality of production, materials, and logistics.

It's clear that adequate investment in packaging can lead to substantial savings by reducing the risk of product damage, returns, and dissatisfied customers. However, this investment must be judicious, as over-engineering packaging can unnecessarily inflate costs without providing proportional benefits. Therefore, a targeted approach, one that tailors the design to the specific needs and risks associated with each product, is paramount.

By implementing thoughtful design principles, utilizing robust packaging materials judiciously, and conducting rigorous pre-shipment testing, companies can ensure product safety while also managing their bottom line. This strategic approach not only reflects a commitment to delivering products in top condition but also signifies an understanding of the importance of cost control in maintaining a competitive edge in the marketplace.

In summary, the balance of safety and cost in packaging design is not a compromise but a strategic alignment that when achieved, delivers undeniable value to both the customer and the business. As the industry evolves and new threats and solutions emerge, revisiting this balance becomes an ongoing process of refinement and optimization for the conscientious brand.

Essential Packaging Safety: Minimizing Risks in Transit

What are the primary types of packaging hazards?

The primary packaging hazards include shock (from impacts and drops), vibration (from transportation), compression (due to stacking), and atmospheric conditions (like temperature and humidity changes).

How can shock hazards be prevented during packaging?

Shock hazards can be minimized by using cushioning materials, conducting drop tests to assess packaging durability, and by designing robust packaging with appropriate cushioning to absorb impacts.

What strategies can be employed to protect against vibration hazards?

To protect against vibration hazards, utilize stabilizing materials, secure the product firmly within the packaging, and consider the transportation mode when designing the packaging to buffer against vibrations.

What measures can reduce the risks of compression on packaged goods?

Compression risks can be reduced by establishing safe stacking protocols, designing reinforced packaging, using box liners for added strength, and employing interlocking patterns for even weight distribution.

Why is pre-shipment testing important for packaging?

Pre-shipment testing helps ensure packaging safety by simulating transport conditions and identifying vulnerabilities. This testing, according to standards like ISTA 3A, allows for corrections to enhance packaging resilience before products are shipped.