Table of Contents:

Understanding Plastic Trays and Their Versatility

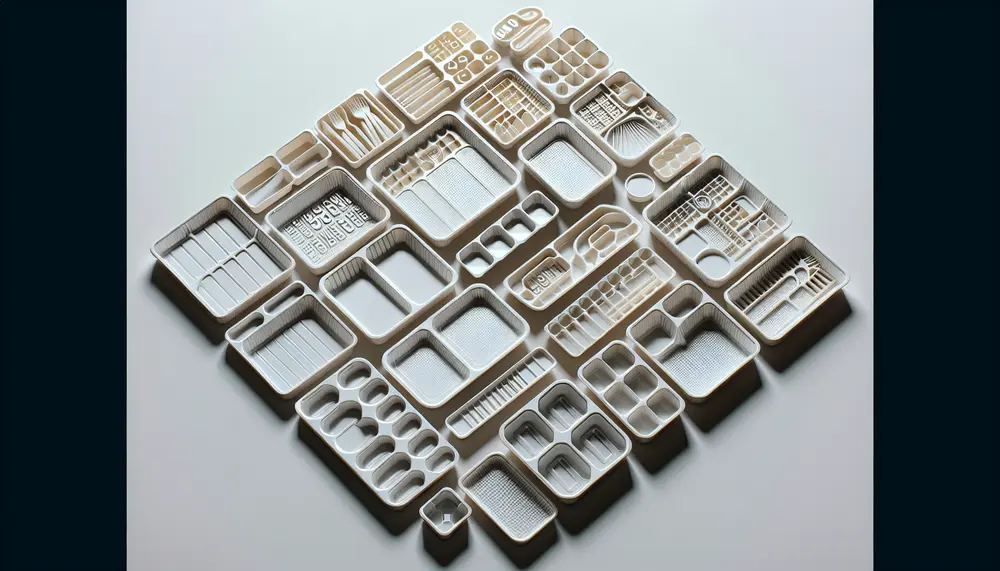

At the core of packaging essentials, plastic trays stand out as the backbone of product storage and transportation. These trays, crafted from various types of polymers, offer an impressive range of functionality that serves countless industries. From the simple task of organizing parts in a warehouse to the complex requirements of sterilized medical packaging, the role of plastic trays cannot be overstated. Their versatility shines through their ability to be customized in size, shape, and material to fit specific purposes. This adaptability has made plastic trays indispensable in settings where precision and reliability are pivotal.

Moreover, plastic trays come in a spectrum of designs, each with unique attributes. For instance, compartmentalized trays effectively separate different items, while vented ones ensure airflow for perishable goods. The durability and lightweight nature of plastic also contribute to their widespread use, proving to be both cost-effective and user-friendly. From eco-friendly options that decrease environmental impact to smart innovations improving safety and convenience, plastic trays have evolved to meet modern demands. This evolution has enabled them to maintain their status as a preferred choice for packaging solutions, reflecting their incredible versatility.

Types of Plastic Trays for Various Applications

Delving deeper into the world of plastic trays, it's important to recognize the array of types available, each suited to particular applications. Thermoformed trays, for example, are widely appreciated for their precision in shaping, which makes them ideal for packaging electronics or medical equipment. These trays are formed under heat to snugly fit items, providing both protection and a clear showcase of the product.

For the catering and food service industry, food-grade plastic trays are indispensable. They are designed to meet strict health standards and can be found in a range of options including freezer-safe, microwaveable, and dishwasher-safe versions. Shipping and logistics trays, on the other hand, are built for durability to withstand the rigors of transportation. They may include reinforced edges or stackable designs that optimize space and ensure stability during transit.

In retail settings, display trays are used to present products attractively, often with an emphasis on transparency and aesthetics to enhance customer appeal. Meanwhile, industrial trays tend to favor function over form, constructed for heavy-duty use and repeated handling in factories and assembly lines.

For specialized tasks, there are also antistatic trays to protect sensitive electronic components from static discharge, and biodegradable trays that offer a more sustainable choice for environmentally conscious operations. Selecting the appropriate type of plastic tray for the intended application is critical for achieving efficiency, safety, and cost-effectiveness.

Assessing the Pros and Cons of Plastic Trays

| Pros of Plastic Trays | Cons of Plastic Trays |

|---|---|

| Lightweight and easy to handle | Can contribute to plastic waste if not recycled |

| Durable and long-lasting | Non-biodegradable and can be harmful to wildlife |

| Affordable and cost-effective | Potential chemical leaching into food |

| Resistant to moisture and many chemicals | Not always recyclable, depending on the type of plastic |

| Available in a variety of sizes and shapes | Production emits pollutants and contributes to global warming |

The Benefits of Using Plastic Trays in Packaging

The use of plastic trays in packaging systems brings a host of benefits that cater to the practical needs of businesses and consumers alike. One notable advantage is their lightweight nature, which reduces shipping costs and eases the burden on transportation logistics. This quality is particularly valuable in today's global marketplace, where the efficiency of supply chain operations is critical.

Another important benefit is the protection they offer. Plastic trays are tough and resist impacts, effectively safeguarding products during shipping and handling. Additionally, their inherent flexibility allows for the absorption of shocks and vibrations, minimizing the risk of damage to delicate items.

Cost savings are also a major advantage. Plastic trays can be produced in large quantities at a relatively low cost, especially when compared to alternatives like metal or glass. This affordability does not come at the expense of quality, as modern plastics can be engineered to meet stringent specifications for strength and durability.

The ease of customization is a further boon. Plastic trays can be tailored to the exact size, shape, and functionality required for specific items, enhancing the overall aesthetic of the product packaging and creating a more appealing unboxing experience for the end-user.

Finally, their ease of cleaning and maintenance makes plastic trays a hygienic option for industries where cleanliness is paramount. With the capability to withstand harsh cleaning agents and high temperatures, these trays ensure that hygiene standards are consistently met.

How to Choose the Right Plastic Tray for Your Needs

Selecting the right plastic tray for your specific requirements involves considering several key factors. Start by assessing the intended use of the tray to determine the level of durability and type of material needed. Will the tray be used for heavy industrial components or delicate electronics? This use-case will direct the selection process significantly.

Next, consider the dimensional requirements. The size and shape of the tray should accommodate the items it will hold, with adequate space for ease of access while preventing unnecessary movement that could result in damage.

Environmental factors, such as exposure to extreme temperatures, chemicals, or UV light, also play a critical role. It's essential to choose a tray material that can withstand these conditions without degrading. For example, certain plastics are better suited for outdoor use, while others are ideal for freezer storage.

Compliance and certifications may be required depending on the industry. For food-related applications, the plastic must be food-safe and FDA compliant. In electrically sensitive environments, choosing antistatic or conductive materials might be mandatory.

Finally, look at the lifecycle and sustainability aspects. Will the tray be used once, or does it need to be durable for multiple uses? If environmental impact is a concern, consider trays made from recycled materials or those that can be easily recycled or biodegraded after use.

By meticulously evaluating these points, you can ensure that the plastic tray chosen will not only meet but exceed your packaging requirements, offering efficiency, safety, and reliability.

Sustainability and Recycling of Plastic Trays

In today's environmentally conscious world, the sustainability and recycling potential of packaging materials are crucial considerations. Plastic trays, when designed and used thoughtfully, can align with sustainability goals. To realize this, engaging in responsible sourcing of materials is a pivotal first step. Opting for trays made from recycled plastic is a proactive choice that reduces waste and the demand for virgin resources.

In terms of recyclability, it's essential to understand the type of plastic the tray is made from. Plastics such as PET, HDPE, and PP, are widely accepted by recycling programs and can be reprocessed multiple times without significant degradation of quality. When selecting plastic trays, aim for types with well-established recycling streams. This foresight ensures that the trays, once they have served their purpose, can be efficiently recycled into new products, thus contributing to a circular economy.

Another aspect of sustainability is the design of the tray itself. Manufacturers are increasingly creating trays that require less material without compromising structural integrity. This reduction in material use not only decreases production costs but also lessens the environmental footprint of the tray.

Additionally, considering the end-of-life scenario of the product is essential. Are the trays designed for disassembly or reuse in other applications? Options such as modular designs or trays that can be repurposed can significantly extend the life of the material.

With a combined effort from manufacturers and consumers to prioritize eco-friendly practices, the use of plastic trays can be part of a sustainable future. It is the shared responsibility of all stakeholders to ensure that plastic trays are used judiciously and disposed of correctly to minimize environmental impact.

Innovations in Plastic Tray Manufacturing

The manufacturing of plastic trays has seen significant advancements, driven by technology and a push towards more efficient and sustainable practices. Innovation in the field has led to the development of smarter materials and processes that enhance the properties of trays while mitigating environmental impact.

One key area of progress is the use of bioplastics. These materials, derived from renewable resources like plant starches, can reduce reliance on fossil fuels and offer better biodegradability than traditional plastics. The production of bioplastic trays is a step towards reducing the carbon footprint of the packaging industry.

Advances in 3D printing technology have also unlocked new possibilities. With this technique, highly customized tray designs can be produced rapidly and on-demand, minimizing waste produced from excess inventory and enabling quick prototyping for bespoke applications.

Smart design software is another tool that is reshaping tray manufacturing. These programs enable engineers to simulate different design scenarios and optimize trays for material usage, weight, strength, and compatibility with items being packaged.

Finally, the integration of nano-materials into plastic trays has begun to add functionalities such as increased strength, flame resistance, or antimicrobial properties, making them suitable for more demanding applications that were previously untenable for plastic solutions.

These emerging technologies and materials ensure that the manufacturing of plastic trays remains a dynamic and evolving industry, capable of meeting the challenges of modern packaging needs while prioritizing environmental responsibilities.

Maintaining and Cleaning Your Plastic Trays

Proper maintenance and cleaning are essential to extend the life of your plastic trays and ensure they remain hygienic and functional. For general maintenance, avoid using abrasive materials that could scratch and compromise the surface. Instead, use a soft cloth or sponge with warm water and mild detergent to clean the trays effectively.

For more thorough cleaning, especially in the food industry or medical settings where sanitation is paramount, consider using a diluted bleach solution or a specific plastic-safe disinfectant. Ensure the cleaning agent is compatible with the type of plastic to prevent any chemical damage.

It's also advisable to regularly inspect plastic trays for any signs of wear and tear such as cracks or deformation. This inspection can prevent potential contamination or failure during use, which is especially important when the integrity of the product is crucial.

For those using dishwasher-safe plastic trays, the convenience of machine washing streamlines the sanitation process. However, always follow the manufacturer's instructions regarding maximum temperatures and recommended cleaning agents to avoid warping or melting.

By adhering to these maintenance and cleaning guidelines, you can keep your plastic trays in optimal condition, promoting safety, functionality, and longevity.

Plastic Trays in the Food Industry: Safety and Standards

In the food industry, plastic trays are an integral component of packaging, serving, and storing food products. The safety and quality of these trays are governed by rigorous standards to ensure they are safe for use with food. The materials used must be food-grade, which means they cannot contain harmful chemicals that could leach into food.

Compliance with regulatory standards such as the FDA (Food and Drug Administration) in the United States or EFSA (European Food Safety Authority) in Europe is a must. These organizations set the guidelines for plastic materials that come into direct contact with food, ensuring they are free from toxins and are manufactured under hygienic conditions.

Additionally, for consumer safety, plastic trays used in the food industry often need to be capable of handling a variety of temperatures, from those required for freezing to those needed for reheating in a microwave. This calls for plastics that are resistant to cracking or changing shape under temperature fluctuations.

It's also imperative for businesses to adhere to proper labeling practices. Labels should provide clear information on the intended use of the tray, including whether it is microwave safe, dishwasher safe, or meant for single use. This transparency helps consumers to use the products responsibly and safely.

Through adherence to these safety standards and regulations, the food industry can ensure that plastic trays are used securely and functionally, supporting public health and consumer trust.

Custom Plastic Trays: Tailoring to Specific Requirements

The expanding role of custom plastic trays in various industries cannot be overstated. These tailored solutions provide an exact fit for products, ensuring optimal protection and presentation. The customization process often begins with a detailed analysis of the item to be packaged, followed by precision engineering of the tray to the exact specifications.

Utilizing advanced design software, manufacturers can create prototypes that accurately reflect the final product. This allows for any necessary adjustments to be made early in the design process, saving time and resources. Through techniques like thermoforming and injection molding, customized trays are then produced to meet these detailed requirements.

Custom trays are not only about fitting the dimensions of a product. Designers also consider factors such as ease of handling, stackability for transportation, and how the product will be displayed on the shelf. Features like snap-on lids, living hinges, and compartments can be incorporated to enhance functionality.

Moreover, custom plastic trays can reflect a brand's commitment to sustainability. Options such as using recycled materials or designing for recyclability are considered from the onset, aligning the product with environmental goals without sacrificing quality or performance.

The result is a plastic tray that not only serves its purpose efficiently but also adds value to the product it holds through enhanced protection, aesthetics, and brand alignment.

The Future of Plastic Trays: Trends and Predictions

As with many industries, the future of plastic trays is shaped by evolving trends and technological advancements. One major trend is the increasing demand for eco-friendly materials. In response, manufacturers are developing trays with biodegradable plastics or sourcing from waste streams, such as ocean-bound plastic, to create products that are less harmful to the environment.

Another development is the rise of smart packaging. Plastic trays are being equipped with technologies like RFID tags and QR codes, providing enhanced tracking capabilities and interactive customer experiences. This integration of technology improves supply chain visibility and offers greater convenience for users.

Automation and AI also play a significant role in the future of plastic tray manufacturing. Automated production lines and AI algorithms optimize the design and manufacturing process, reduce material waste, and enhance the precision of custom tray production.

In retail, there is a growing focus on the in-store experience. Plastic trays are expected to evolve to become more engaging and visually appealing, using color, texture, and form to attract consumers and facilitate brand differentiation on crowded shelves.

These trends, coupled with ongoing research into new materials and processes, hint at a future where plastic trays are not only more sustainable and efficient but also align seamlessly with the digital and brand-centric landscape of the packaging industry.

Comparing Plastic Trays with Other Material Options

When selecting the ideal material for trays, comparing plastic trays with other materials is imperative to making an informed choice. Plastic trays often provide a cost-effective and versatile solution, but how do they stack up against alternatives like metal, wood, or glass?

Metals trays, for instance, are known for their durability and longevity. They can withstand extreme conditions and heavy use. However, metal is typically heavier and more expensive than plastic, which can influence handling and transportation costs.

Wooden trays bring a natural aesthetic and might be considered for their renewable qualities. Yet, they require more maintenance and aren't as moisture resistant as plastic, leading to potential hygiene concerns in specific applications.

Glass trays offer an elegant appearance and are commonly used in consumer-facing scenarios. They are easy to clean and disinfect, but their fragility and weight limit their usefulness in high-turnover or transport-intensive environments.

Each material has its unique advantages and constraints. When making a decision, factors such as the intended use, necessary durability, weight, cost, and environmental impact must all be evaluated. Plastic trays often emerge as a balanced option, offering a compromise between performance, aesthetics, and sustainability.

Cost-Effectiveness of Plastic Trays for Businesses

The cost-effectiveness of plastic trays is a significant factor for businesses considering the bottom line. Their affordability is largely due to the economies of scale in production, where large quantities can be manufactured quickly and with relatively low material costs. The efficient production process of plastic trays often results in a lower unit price compared to other material options.

Additionally, plastic trays are lightweight, which translates to savings on shipping and handling. Less weight means lower transportation costs, and the ability to move more products at once, improving overall logistics efficiency. This weight advantage also contributes to reducing the carbon footprint associated with the transport of goods.

Another aspect to consider is their durability. Plastic trays can withstand repeated use and handling, which means they need to be replaced less frequently. This long service life reduces the need for ongoing purchasing, offering longer-term savings over disposable alternatives.

The maintenance of plastic trays also plays a role in their cost-effectiveness. Being easy to clean and resistant to many chemicals, they do not require specialized and costly maintenance protocols, saving businesses further costs in labor and care.

These combined factors make plastic trays an attractive option for businesses looking to optimize their operational expenses without sacrificing quality or performance.

Plastic Tray Storage Solutions for Home and Industry

Plastic trays serve as invaluable storage solutions across various settings, from home kitchens to industrial warehouses. Their modularity and stackability make organizing items simple and efficient, capitalizing on vertical space while maintaining easy access.

In the home, plastic trays help to organize drawers, refrigerators, and pantries, keeping items separated and orderly. Clear trays allow for quick identification of contents, reducing clutter and making better use of limited space.

For industrial use, plastic trays are designed to integrate seamlessly into inventory systems. They facilitate the sorting of components, streamline assembly line processes, and improve overall workflow. Heavy-duty trays can be used for bulk storage, capable of holding significant weights and withstanding the frequent movement associated with warehouse logistics.

The adaptability of plastic trays to various storage systems is also a key feature. Their design can be customized to fit shelving units, conveyor belts, and automated storage and retrieval systems (AS/RS), further enhancing operational efficiency.

Overall, plastic tray storage solutions prove beneficial due to their flexibility, durability, and cost savings. They exemplify a simple, yet effective means of organizing and protecting items in both personal and professional environments.

Design Features That Enhance the Functionality of Plastic Trays

Plastic trays can incorporate a multitude of design features that enhance their practicality and functionality. For instance, reinforced edges can be added to increase strength and durability for heavier loads, ensuring the trays can be used and reused without compromise to their structural integrity.

Ergonomic aspects are also essential, such as textured grips or handles, which make handling and transporting trays more comfortable and secure, reducing the risk of drops or spills, especially in fast-paced work environments.

Versatility is achieved through features like removable or adjustable dividers, allowing users to customize the internal layout according to the items being stored or transported. Some trays also offer lids or covers for added protection against dust, moisture, or accidental opening.

Drainage holes or channels can be crucial for applications involving liquids, promoting air circulation and speeding up the drying process, crucial in food service or medical settings where hygiene is paramount.

Lastly, color coding is an intelligent design choice that facilitates inventory management and sorting. Different color trays can designate specific uses or contents, making workflows more intuitive and reducing the time spent searching for items.

Such thoughtful design features not only extend the functionalities of plastic trays but also contribute to user safety, satisfaction, and operational efficiency.

Case Studies: Successful Use of Plastic Trays in Various Sectors

Case studies highlight the successful implementation of plastic trays across diverse sectors, demonstrating their adaptability and efficiency. In the healthcare industry, for instance, sterilizable plastic trays have streamlined the organization and handling of medical instruments, contributing to enhanced safety and faster turnaround times in hospitals.

In the electronics sector, antistatic plastic trays have been used to protect sensitive components during manufacture and shipping, drastically reducing the incidence of electrostatic discharge-related damage and associated financial losses.

The food and beverage industry has benefited from the use of food-grade, durable plastic trays in quick-service restaurants, facilitating the hygienic display, serving, and transport of food items while meeting rigorous health standards.

Logistics and warehousing operations have seen improvements in efficiency and organization through the customization of plastic trays to fit specific product dimensions and weights, enhancing the storage density and accessibility of inventory items.

Lastly, in retail, display trays made of high-clarity plastic have improved product visibility and appeal, leading to increased sales and customer satisfaction. These case studies underscore the value addition and problem-solving capabilities plastic trays deliver in real-world applications.

Conclusion: Why Plastic Trays Are a Smart Choice

In conclusion, plastic trays exhibit a remarkable combination of versatility, durability, and cost-efficiency, making them a smart choice for a myriad of applications across industries. Their lightweight composition reduces shipping costs, while their robustness ensures long-term use and sustainability. With the ability to be customized to any shape and size, they meet specific needs while providing protection and organizational benefit.

Advancements in eco-friendly production methods and recycling initiatives further enhance the appeal of plastic trays as a conscious choice that supports sustainability goals. Whether in the home or in highly regulated environments such as healthcare and food service, plastic trays offer a reliable and practical solution that aligns with both economic and environmental objectives.

The ongoing innovations within the sector promise a future of even greater possibilities, ensuring that plastic trays remain an indispensable tool for storage, transportation, and presentation of products. Reflecting on the highlighted case studies, the success stories of plastic trays across sectors bolster the argument for their selection as a preferred packaging and organizational medium.

Frequently Asked Questions About Plastic Trays

What types of plastic are used to make trays?

Trays can be made from a variety of plastics, including PET (polyethylene terephthalate), HDPE (high-density polyethylene), and PP (polypropylene). Each type offers different characteristics in terms of strength, durability, and recyclability.

Are plastic trays safe for food storage and preparation?

Yes, many plastic trays are designed for food-related applications and are made from food-grade materials that meet health and safety standards. They are safe for food storage and preparation as long as they specified as food-safe by the manufacturer.

How can I recycle my plastic trays?

To recycle plastic trays, first clean them and remove any attached labels. Check the recycling symbol on the tray to identify its resin code and ensure your local recycling program accepts that type of plastic. Place the tray in the appropriate recycling bin or take it to a recycling center.

Can plastic trays be customized for specific uses?

Yes, plastic trays can often be customized in size, shape, and material to fit specific purposes. Customization options include adding compartments, handles, and choosing different colors or materials, depending on the manufacturer's capabilities.

What are the benefits of using plastic trays over other materials?

Plastic trays are lightweight, durable, and cost-effective. They offer a versatile and hygienic solution for storage and transport, and many can be recycled. Plastic trays can also be manufactured to a wide variety of specifications, meeting diverse industry standards and consumer needs.