Understanding MOSH/MOAH in Packaging: A Beginner's Guide

When it comes to food safety and quality, the terms MOSH and MOAH hold significant importance. These acronyms stand for Mineral Oil Saturated Hydrocarbons and Mineral Oil Aromatic Hydrocarbons respectively. They are chemical substances found in a diverse range of products, including packaging materials, which can migrate into food and raise health concerns.

MOSH, the saturated part of these hydrocarbons, typically do not pose a severe health risk. However, they can accumulate within the body, primarily in fatty tissues and organs. MOAH, on the other hand, consist of compounds that may contain harmful elements, potentially acting as carcinogens and raising the risk for consumer health.

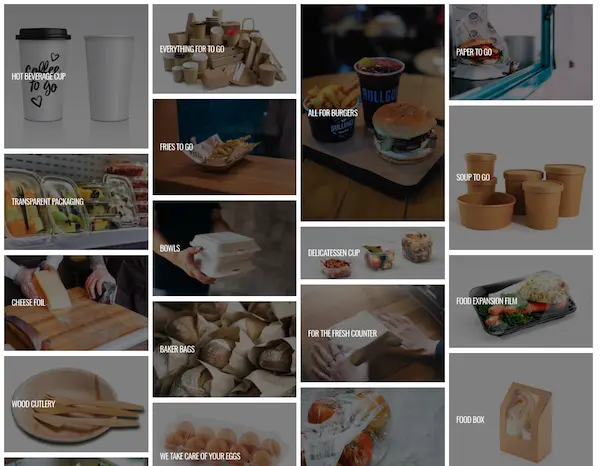

With our network with packaging suppliers along with a huge international network, we provide customizable logistic packaging services as per the needs and requirements of our clients, in order to maintain continuous product development and greatly reduce the spending for packaging solutions.

Understanding the impact of MOSH/MOAH involves a multi-faceted approach. We consider their chemical properties, origins, and the pathways through which they enter the food supply. Their presence in packaging demands close attention, as they often find their way into foods through direct contact with recycled cardboard or plastic, inks, adhesives, and during the manufacturing and transportation process.

The complexities of MOSH/MOAH chemistry and their interaction with food products mean that ongoing research is crucial. Industries and regulators are continuously developing testing methods to detect and quantify their presence accurately. Awareness and understanding of MOSH/MOAH will empower consumers and businesses to make informed decisions, ensuring product safety and maintaining public health.

What Are MOSH and MOAH? Defining the Basics

In the realm of packaging and food safety, understanding the distinction between MOSH and MOAH is crucial. These compounds are types of mineral oil hydrocarbons, which are derived from the same origins but have different structural properties and health implications.

The MOSH category comprises a large group of chemical substances known as alkanes and cycloalkanes. Due to their saturated nature, they are generally less reactive chemically, which is why they are less likely to cause acute toxic effects. However, their capability to bioaccumulate over time in human tissue necessitates cautious monitoring and management.

Conversely, MOAH are characterized by their rings or aromatic structures. This category encompasses a varied collection of compounds, including some that have raised health concerns due to their potential mutagenic and carcinogenic properties. Due to this, detecting and controlling MOAH levels in packaging intended for food contact is of paramount concern for both industry players and regulatory bodies.

Both MOSH and MOAH are omnipresent in our environment and can be formed naturally or synthetically. Their presence in packaging materials can be traced back to various sources, such as the refining process of crude oil, or from contact with machines and processes that employ mineral oils during manufacturing.

Potential Risks and Benefits of MOSH/MOAH in Food Packaging

| Pros of MOSH/MOAH in Packaging | Cons of MOSH/MOAH in Packaging |

|---|---|

| Can help to increase shelf-life of products | Potential human health risks upon consumption |

| Provides a barrier to moisture and gases | Difficulties in recycling and environmental impact |

| Might reduce food waste over time | Lack of full scientific consensus on safety |

| Can improve product's flavor and freshness preservation | Possible accumulation in the human body |

The Sources of MOSH/MOAH in Packaging Materials

Pinpointing the origins of MOSH and MOAH is essential for managing their presence in packaging. These substances can infiltrate packaged goods through several pathways. Common sources include printing inks and recycling processes, where oils from previously printed materials may leach into recycled packaging.

Additionally, packaging adhesives and coatings might also be responsible for MOSH/MOAH contamination. These elements can silently migrate into the packaged content, raising potential concerns if the packed goods are consumable products. Notably, production processes that involve the use of machinery lubricated with mineral oils are yet another notable contributor to the presence of MOSH/MOAH in packaging.

The risk increases with direct contact between the packaging material and foodstuffs, which is why packaging destined for food use demands strict vigilance. Indirect contamination can also take place through the ambient environment where packaging is stored before its use, as these hydrocarbons are widespread in the air due to various anthropogenic activities.

Given the associated risks, the packaging industry strives to implement tighter controls and cleaner technology to effectively manage MOSH/MOAH levels. This includes exploring alternatives for ink formulations, enhancing recycling methods to remove these substances, and refining other aspects of the production line to minimize possible contamination.

Health Implications of MOSH/MOAH in Food Packaging

The health implications of MOSH and MOAH have become a topic of concern and active research in the field of food safety. Understanding how these substances can affect human health is critical for consumers and industry regulators. While MOSH compounds have a tendency to bioaccumulate, MOAH compounds are typically viewed with higher concern due to their potential carcinogenic effects.

Scientific studies have indicated that certain types of MOAH have the potential to be mutagenic, interfering with normal cellular DNA. This interaction poses a concern that prolonged exposure could lead to long-term health risks, including cancer. Consequently, many health organizations advocate for stringent limit values for MOAH presence in food contact materials.

The potential health risks have led to increased scrutiny by food safety agencies. Regular risk assessments are conducted to determine the potential impact on different population groups, including vulnerable ones such as children and pregnant women. The objective is to protect public health by establishing safe levels of exposure and enforcing them through regulatory requirements.

As new research unfolds, the packaging industry is prompted to respond with enhanced material choices and processing methods. The goal is to ensure that packaged food remains safe and that the risk associated with MOSH/MOAH exposure is kept to a minimum. Understanding these concerns is the first step towards mitigating potential health risks associated with food packaging.

Detecting and Measuring MOSH/MOAH in Packaging Products

Detecting and quantifying MOSH/MOAH levels in packaging products is a sophisticated process that requires state-of-the-art analytical techniques. One standard method involves using gas chromatography combined with mass spectrometry (GC-MS) to identify and measure the specific hydrocarbons present in packaging materials.

A crucial step in the detection process is the extraction of oils from the packaging material, which is typically done using solvents. Following extraction, the solvent is evaporated, and the residue is analyzed. This analysis not only confirms the presence of MOSH/MOAH but also quantifies their concentrations, which is vital for compliance with existing health and safety standards.

With advancements in analytical methods, laboratories now can achieve higher sensitivity and specificity in their results, allowing for better detection of even trace levels of these substances. Regular monitoring becomes a mandatory practice for quality control, ensuring that the packaging meets stringent regulatory requirements concerning MOSH/MOAH contamination.

The role of such testing is instrumental in maintaining consumer confidence and safeguarding public health. By consistently applying these measures, the packaging industry can provide safer products and navigate the challenges presented by MOSH/MOAH risks.

Regulatory Standards for MOSH/MOAH in Packaging Industry

The packaging industry is guided by a framework of regulatory standards designed to limit the levels of MOSH/MOAH. These standards are set by various international and national agencies to protect consumer health and prevent the harmful effects of these hydrocarbons.

In Europe, for instance, the European Food Safety Authority (EFSA) has conducted thorough risk assessments and has published opinions on the acceptable thresholds for MOSH and MOAH in food packaging. Although specific binding legislation for MOSH/MOAH is not in place EU-wide, some individual countries have established their own limits and guidelines to regulate the permissible levels in food contact materials.

The German Federal Institute for Risk Assessment (BfR) and other regulatory bodies have been at the forefront of this movement, recommending maximum limits for MOSH/MOAH migration into food products. Industries are expected to rigorously test their packaging using approved analytical methods to demonstrate compliance with these specifications.

While the United States does not have specific regulations for MOSH/MOAH in place, the Food and Drug Administration (FDA) oversees the safety of food contact substances and can indirectly control MOSH/MOAH presence through its general safety provisions.

Adherence to these regulatory standards is not only a legal requirement but a critical factor in maintaining brand integrity and the trust of consumers. As a result, packaging companies invest in comprehensive quality control processes to ensure ongoing compliance with all MOSH/MOAH regulations.

Best Practices to Minimize MOSH/MOAH Contamination

Employing best practices is essential for minimizing the potential for MOSH/MOAH contamination in packaging products. These include proactive approaches in material selection, manufacturing processes, and product design.

Selecting high-quality raw materials that are free from or have reduced levels of mineral oil is a key starting point. Packaging companies are also encouraged to use alternatives to recycled fibers or ensure that recycled content is thoroughly purified to remove any possible contaminants.

- Implementation of barriers such as functional coatings or liners that can prevent the migration of MOSH/MOAH from packaging into the product

- Regular maintenance and cleaning of machinery to eliminate mineral oil residues

- Substitution of mineral oil-based lubricants and inks with safer, non-MOH alternatives

- Thorough quality control checks, including routine testing for MOSH/MOAH levels

Additional measures include optimizing storage conditions to reduce environmental contamination and adopting best practices in the supply chain to ensure that packaging is handled in ways that don't introduce MOSH/MOAH.

These collective efforts are crucial for maintaining high standards of food safety and protecting consumers from potential health hazards associated with MOSH/MOAH.

Innovations in Packaging to Reduce MOSH/MOAH Levels

With the growing concern over MOSH/MOAH contamination, the packaging industry is embracing innovative solutions to address this challenge. These advancements aim to enhance the safety and integrity of packaging while retaining functional and aesthetic qualities.

One area of innovation involves the development of new barrier technologies. These barriers are specifically designed to blocK MOSH/MOAH migration, maintaining the quality of the food products within. Modern coatings and films now incorporate materials that serve as effective barriers while still complying with environmental and health standards.

Another forward-looking approach is the use of alternative substances in the production process. From biodegradable oils to plant-based inks, there is a concerted effort to identify and utilize materials that do not contribute to MOSH/MOAH issues.

Advances in packaging design also play an important role. Engineers and designers are working on creating packaging structures that minimize direct contact between the packaging material and the food product, thereby reducing the risk of hydrocarbon transfer.

The investment in research and development of these innovative strategies underscores the industry's commitment to proactive MOSH/MOAH management and the delivery of safer packaging solutions to the market.

Case Studies: MOSH/MOAH Mitigation Success Stories

The battle against MOSH/MOAH contamination has yielded several success stories, showcasing the effectiveness of mitigation strategies in the packaging industry. These case studies provide valuable insights into the approaches and technologies that can dramatically reduce the presence of these substances in packaged goods.

A breakthrough case involves a major European food producer that collaborated with packaging experts to redesign their food boxes. By integrating specialized barrier layers into the cardboard, they successfully minimized MOSH/MOAH migration to undetectable levels, setting a new industry benchmark.

Another instance of success came from a packaging manufacturer that switched to MOH-free waxes in their production process. This transition not only met the regulatory standards but also received positive feedback from consumers for maintaining product quality and safety.

Furthermore, an international research project led to the development of advanced analytical equipment, enhancing the precision of MOSH/MOAH detection. This technology is now widely used by packaging companies to conduct regular testing for compliance assurance.

These case studies underscore the tangible progress made in reducing MOSH/MOAH hazards and demonstrate the packaging industry's capacity for innovation when it comes to protecting consumer health.

The Future of MOSH/MOAH Regulation in Packaging

As awareness of MOSH and MOAH and their potential health impacts grows, the future of their regulation in packaging appears set for evolution. The call for stricter controls and lower tolerance levels will likely drive changes in industry standards and legislation.

Looking ahead, we can expect regulatory bodies to refine and enforce stricter limits on MOSH/MOAH content in food contact materials. These changes may include the introduction of new testing procedures to enhance the reliability and accuracy of MOSH/MOAH detection.

There is also a strong possibility of a more standardized global approach to MOSH/MOAH regulation. Harmonization of standards can facilitate international trade, simplify compliance procedures, and provide clear guidance for packaging manufacturers around the world.

In addition to regulatory changes, we anticipate continued innovation in packaging materials and technology to further mitigate the risks associated with MOSH/MOAH. Research and collaboration across sectors will be crucial in developing safe and sustainable packaging solutions.

The momentum for change in the realm of MOSH/MOAH regulation suggests a proactive stance from all stakeholders, emphasizing health and safety without compromising the functionality and efficacy of packaging materials.

Conclusion: Embracing Safer Packaging Solutions

In conclusion, the collective efforts to understand, detect, and reduce MOSH/MOAH have commenced a new era in the packaging industry. It's an era marked by a commitment to not only functionality and design but also to health and environmental consciousness.

Industry leaders, regulatory bodies, and scientific researchers are collaborating in unprecedented ways to establish safer packaging practices. The result is an emerging portfolio of materials and technologies that assure consumer safety and uphold a brand's promise of quality.

As regulations evolve to become more rigorous and our scientific understanding deepens, we will continue to see novel and improved packaging solutions. These solutions will likely exceed current safety standards and consumer expectations, ensuring that the food we consume is protected by packaging that does not compromise our health.

Ultimately, the goal is to maintain a delicate balance—innovating to enhance packaging performance, while rigorously managing the risks posed by MOSH/MOAH. As this balance is continually achieved, consumers and industry members can look forward to a future where packaging safety is given the priority it rightfully deserves.

Key Insights on MOSH/MOAH in Food Packaging Safety

What are MOSH and MOAH in the context of food packaging?

MOSH (Mineral Oil Saturated Hydrocarbons) and MOAH (Mineral Oil Aromatic Hydrocarbons) are chemical substances found in mineral oils. They can migrate from packaging materials into food, raising health concerns due to their potential accumulation in human tissue and carcinogenic properties.

How can MOSH and MOAH enter food products?

MOSH and MOAH can enter food products through direct contact with packaging materials, such as recycled cardboard or plastics that contain mineral oils. They can also migrate from printing inks, adhesives, and coatings used in packaging, as well as from lubricants and other substances used in food production processes.

What are the health risks associated with MOSH and MOAH?

MOSH can accumulate within the human body, mainly in fatty tissues and organs. MOAH, on the other hand, may contain harmful elements, with some compounds being potentially mutagenic and carcinogenic. There are concerns that prolonged exposure to MOAH could lead to health risks, including cancer.

What regulations exist to control MOSH/MOAH levels in packaging?

Regulatory bodies, such as the European Food Safety Authority (EFSA), and individual countries have established guidelines and recommendations to limit the presence of MOSH/MOAH in food packaging. While specific legislation varies by region, industries are expected to monitor and manage MOSH/MOAH levels to ensure consumer safety.

How can consumers minimize exposure to MOSH/MOAH?

Consumers can minimize exposure to MOSH/MOAH by being aware of the packaging materials used for food products and choosing items with minimal or no recycled content in direct contact with food. Additionally, consumers can look for products from companies that implement proactive measures to reduce MOSH/MOAH in their packaging.