Understanding Industrial Food Packaging

Industrial food packaging plays a pivotal role in the global food industry, ensuring that products are safely delivered from farms and factories to tables around the world. This type of packaging is designed to meet the rigorous demands of mass production, distribution, storage, and retail. It encompasses a variety of materials including plastics, metals, glass, and paper products, each chosen for its specific properties like durability, lightness, or barrier protection against contaminants and degradation.

The main objective of industrial food packaging is to protect food products from environmental factors and physical damage during transportation and storage, thus preserving their quality, freshness, and safety. Additionally, it aims to provide convenience for consumers and enhance the efficiency of supply chains by incorporating features such as easy-open mechanisms, resealable closures, and compact designs.

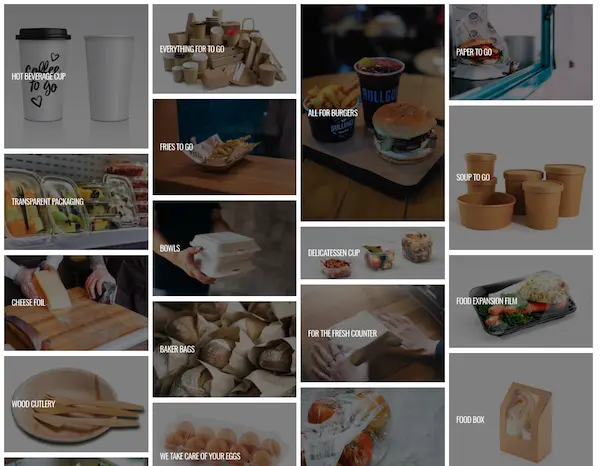

With our network with packaging suppliers along with a huge international network, we provide customizable logistic packaging services as per the needs and requirements of our clients, in order to maintain continuous product development and greatly reduce the spending for packaging solutions.

Effective packaging is also crucial for maintaining the nutritional value of food by preventing exposure to air, moisture, and extreme temperatures. Moreover, it plays an essential role in communication by providing vital information about contents, nutritional values, usage instructions, and expiration dates, all of which are mandatory in many countries to ensure consumer safety and informed choices.

Key Innovations in Industrial Food Packaging

Recent advancements in industrial food packaging have been transformative, driving both efficiency and sustainability. Innovations in this field not only respond to consumer demands but also anticipate regulatory pressures towards more eco-friendly solutions. Below are some of the key developments that have reshaped the landscape of food packaging:

- Edible Packaging: This innovation involves creating packaging materials that are safe to eat and can reduce waste. Made from natural ingredients like seaweed or starch, edible packaging is gaining traction in products such as snack bars and condiments.

- Smart Packaging: Integrating technology into packaging, smart solutions offer features like temperature indicators, freshness sensors, and QR codes that link to detailed product information. These technologies enhance product safety by providing real-time data and improving traceability and consumer engagement.

- Biodegradable Plastics: As environmental concerns mount, there has been a push towards plastics that can break down naturally. Biodegradable plastics are engineered to decompose over time under specific conditions, offering a potential reduction in plastic pollution.

- Active Packaging: This technology extends shelf life and maintains freshness by controlling the atmosphere inside the package. Incorporating substances that absorb oxygen, moisture, or ethylene, active packaging actively manages the biochemical or microbial changes that occur during storage.

- Water-soluble Films: Used for small items such as dishwasher tablets or laundry pods, water-soluble films are now being explored for food packaging. These films dissolve when in contact with water, leaving no residue and thus no waste.

These innovative solutions not only enhance the functionality of food packaging but also address critical environmental issues, coupling convenience with sustainability. The combination of traditional materials with innovative technologies reflects the dynamic evolution within the industrial food packaging industry, poised to meet future challenges and consumer needs.

Pros and Cons of Innovations in Industrial Food Packaging

| Pros | Cons |

|---|---|

| Enhanced food safety through improved barrier properties | Potential increase in non-biodegradable waste |

| Extended shelf life of products | High costs associated with new packaging technologies |

| Reduction in food waste | Complex recycling processes for certain materials |

| Innovative designs for better consumer convenience | Possible health risks from new materials |

| Use of smart packaging for better tracking and quality control | Privacy concerns over data handling in smart packaging |

Challenges Facing Industrial Food Packaging

The sector of industrial food packaging faces numerous challenges that impact both the industry and the environment. These challenges require innovative solutions and proactive approaches to ensure the sustainability and efficiency of packaging practices.

- Environmental Impact: One of the most pressing challenges is the environmental footprint of packaging waste. Much of the packaging used today is single-use, contributing to growing landfills and pollution. The industry must continue to develop materials and processes that minimize environmental impact.

- Health and Safety Concerns: Food packaging materials must not only be effective but also safe for consumer health. There is ongoing concern regarding chemicals in packaging materials that can leach into food. Ensuring materials are non-toxic and meet strict regulatory standards is crucial for public health.

- Recycling and Waste Management: Despite advances in packaging materials, recycling rates for some materials remain low due to lack of facilities or complexity in sorting and processing. Improving the recyclability of materials and encouraging consumer participation in recycling programs are vital steps towards sustainability.

- Cost Constraints: Developing and implementing new packaging technologies can be expensive. Balancing cost-effectiveness with innovation and sustainability is a significant challenge for manufacturers, especially in competitive markets.

- Global Supply Chain Complexities: The globalization of food markets introduces complexities in packaging logistics. Adapting packaging to different climates, transportation modes, and regulatory environments can be daunting and requires flexible, durable solutions.

Addressing these challenges demands a multi-faceted approach, encompassing regulatory compliance, technological innovation, consumer education, and collaboration across the supply chain. While there are significant hurdles to overcome, continuous research and development are paving the way for more sustainable and efficient packaging solutions.

Sustainable Solutions in Food Packaging

In response to the environmental challenges posed by traditional packaging methods, the industry is turning towards sustainable solutions in food packaging that reduce ecological footprints and promote recycling and reusability. Here are some innovative approaches being adopted:

- Plant-Based Materials: Many companies are exploring the use of biopolymers derived from plants such as corn, sugarcane, and potatoes. These materials are not only renewable but often compostable, reducing dependence on fossil fuels and decreasing waste in landfills.

- Upcycled Materials: Upcycling uses by-products and waste materials to create new packaging. This not only reduces waste but also minimizes the environmental impact associated with the production of new packaging materials.

- Reusable Systems: To combat the single-use culture, some sectors are developing reusable packaging systems where containers can be returned, cleaned, and reused. This approach is particularly gaining ground in the beverage industry.

- Lightweighting: Reducing the material used in packaging, known as lightweighting, lessens the overall environmental impact from production to transportation. Advances in packaging design are enabling lighter, yet still protective, packaging solutions.

- Enhanced Recycling Technologies: Improvements in recycling technologies are making it easier to recycle previously non-recyclable materials. Innovations include chemical recycling methods that break down plastics into their molecular components to be recreated as new plastics.

These sustainable practices are not just beneficial for the environment but also resonate with increasingly eco-conscious consumers, creating a push for continued innovation and adoption in the industry. The integration of sustainability into packaging strategies is crucial for long-term environmental health and business viability.

The Future of Industrial Food Packaging

Looking ahead, the future of industrial food packaging is poised to be shaped by ongoing innovation and regulatory changes aimed at increasing sustainability and enhancing consumer safety. Here's what we might expect:

- Advanced Biodegradable Options: Continued development in biodegradable materials could lead to new forms that degrade more efficiently and are viable on a commercial scale, reducing the environmental impact even further.

- Expansion of Intelligent Packaging: Smart packaging will grow to include more interactive elements such as RFID tags and sensors that track the condition of the food, thereby improving safety and reducing waste by providing more accurate, real-time data on product integrity.

- Customization through Digital Printing: Digital printing technologies on packaging allow for more personalized, dynamically changeable graphics and information, enhancing branding and consumer engagement without sacrificing speed in packaging production.

- Stringent Regulations: Increased environmental awareness may lead to stricter governmental regulations regarding packaging materials and disposal methods, driving innovation towards sustainability.

- Greater Consumer Involvement: As consumers become more environmentally aware, their influence on packaging trends will grow, pushing companies to adopt practices that are not only eco-friendly but also transparent and aligned with consumer values.

The combination of technological advancements and shifting consumer preferences is shaping a future where food packaging not only serves to preserve and protect food but also contributes positively to the environment and enhances consumer interaction. As the industry continues to evolve, the focus will likely be on developing solutions that balance functionality, environmental responsibility, and cost-effectiveness.

Impact of Technology on Food Packaging

The impact of technology on industrial food packaging has been profound, revolutionizing how products are protected, stored, and presented. Innovative technological advances have led to significant improvements in packaging efficiency and functionality:

- Automation and Robotics: Automated packaging lines and robotic systems enhance precision and speed in the packaging process, significantly increasing throughput and reducing labor costs. These systems allow for more consistent package quality and rapid adjustment to different packaging types and sizes.

- Nanotechnology: The application of nanotechnology in packaging materials can enhance barrier properties against moisture, gases, and UV light. Nanotechnology can be used to incorporate bio-active components that indicate the freshness of the product or release antimicrobial substances to extend shelf life.

- 3D Printing: 3D printing technology allows for rapid prototyping and manufacturing of customized packaging molds and components. This agility accelerates development processes and enables bespoke solutions tailored for specific products or functions.

- Artificial Intelligence (AI): AI is being utilized to optimize packaging systems, predict maintenance needs, and manage inventory. It assists in data analysis to streamline operations and reduce waste by predicting trends and adapting production schedules.

Each technological advancement contributes to a more dynamic and efficient packaging industry, capable of addressing both current consumer demands and future environmental challenges. The ongoing integration of cutting-edge technologies into food packaging processes not only boosts production efficiency but also drives continuous improvement in product safety and sustainability.

Regulatory and Safety Considerations in Food Packaging

In the domain of industrial food packaging, regulatory and safety considerations are paramount. The industry must adhere to stringent standards to ensure that packaging is safe for food contact and that products are protected from contamination:

- Compliance with Food Safety Standards: Packaging materials must meet specific safety criteria set by global and regional regulatory bodies, such as the Food and Drug Administration (FDA) in the USA or the European Food Safety Authority (EFSA) in Europe. These standards help ensure that no harmful substances transfer from the packaging to the food.

- Use of Approved Materials: Only materials that have been approved for food contact, such as certain plastics, glass, and metals, can be used in food packaging. This approval process involves rigorous testing to ensure that materials do not release chemicals at levels harmful to health.

- Labeling Requirements: Accurate labeling is critical for informing consumers about the product and for compliance with food labeling regulations, which include allergen declarations, nutritional information, and usage instructions. Labels must also withstand environmental factors like moisture and heat without degrading.

- Traceability Systems: Implementing traceability mechanisms, often through barcodes or RFID tags, enables tracking of the product through each stage of the supply chain. This improves response times during food safety recalls and helps verify the authenticity and safety of the products.

These considerations are critical not only for consumer safety but also for maintaining trust in food brands and manufacturers. Ensuring compliance with these regulations demands continuous vigilance and adaptation as new materials and technologies emerge, and as regulatory environments evolve.

Case Studies: Success Stories in Industrial Food Packaging

Exploring case studies offers valuable insights into successful applications of innovations in industrial food packaging. These real-world examples highlight the impact of thoughtful design, material selection, and technology integration:

- Sustainable Bottling Solutions: A leading beverage company introduced a new line of water bottles made entirely from recycled plastics (rPET). This initiative not only reduced the company’s carbon footprint but also set a precedent in the beverage industry for environmental responsibility.

- Smart Packaging Implementation: A multinational food corporation implemented smart packaging with freshness sensors for their perishable food items. The sensors provide real-time data to consumers via a smartphone app, indicating the product's freshness and optimal consumption period.

- Edible Packaging Launch: A startup developed an innovative edible wrap for fast-food items, made from seaweed. This packaging solution not only enhances the eating experience by infusing additional flavors but also eliminates waste, aligning with the growing consumer preference for sustainability.

- Advanced Traceability for Meat Products: A meat processing company embraced RFID technology for its packaging, allowing for enhanced traceability and inventory management. This integration resulted in significant improvements in tracking the quality and safety of meat products from farm to table.

These success stories exemplify how embracing new packaging techniques and materials can lead to tangible benefits, including increased consumer satisfaction, reduced environmental impact, and improved operational efficiencies. These innovative strides demonstrate the dynamic nature of the industrial food packaging industry and its ability to adapt to evolving market demands and regulatory pressures.

Optimizing Cost and Efficiency in Food Packaging

Optimizing cost and efficiency in industrial food packaging is crucial for maintaining competitiveness while delivering quality products. Here are targeted strategies that companies are implementing to achieve these economic goals without compromising packaging effectiveness:

- Material Reduction Strategies: Companies are actively looking at ways to reduce material usage without affecting the functional integrity of the packaging. This minimization not only cuts costs but also lessens the environmental impact, adhering to the principles of sustainable packaging.

- Process Reengineering: Revisiting and optimizing packaging lines to streamline operations can lead to significant cost savings. By integrating more automated solutions, companies reduce labor costs and enhance packaging speed and consistency.

- Economies of Scale: By increasing production volumes and standardizing packaging components, companies can leverage economies of scale. Bulk purchasing of materials and a centralized production approach reduce per-unit costs significantly.

- Supply Chain Optimization: Tightening logistics from material sourcing to distribution ensures maximum efficiency. Adopting a just-in-time (JIT) inventory system reduces storage costs and minimizes waste 1.

These measures are supported by continuous improvement programs and technological innovations aimed at reducing waste and enhancing productivity. For instance, adopting lightweight materials can reduce shipping costs significantly, thus optimizing both operational and environmental efficiency.

Investment in new technologies and adherence to lean manufacturing principles are driving the industry forward, shaping a competitive edge by aligning cost-efficiency with sustainable practices. These adaptations ensure that companies can thrive in a market that demands both economic and ecological responsibility.

Consumer Trends Influencing Food Packaging Designs

Consumer preferences play a pivotal role in shaping the design and functionality of industrial food packaging. As market demands evolve, so too do the packaging strategies of manufacturers, keen on aligning their products with consumer trends:

- Convenience: Busy lifestyles are driving the demand for easy-to-use and portable packaging. Designs such as resealable zips, single-serving packages, and microwavable containers are becoming increasingly popular for their convenience.

- Health Consciousness: With a growing emphasis on health and wellness, consumers are seeking packaging that preserves the nutritional benefits of food. Packaging that features transparent sections allowing visibility of contents and labels that highlight organic or all-natural ingredients cater to this need.

- Eco-Friendliness: Increasing awareness of environmental issues has led to a preference for sustainable packaging options. This trend is evident in the popularity of packaging made from recycled or biodegradable materials, and minimalistic designs that use less material overall.

- Aesthetics and Branding: In a competitive market, visually appealing packaging can greatly influence purchasing decisions. Bold colors, unique shapes, and engaging textures are employed to attract consumer attention and reflect brand identity.

- Personalization: Advances in digital printing technologies have made personalized packaging a feasible option for many companies. This allows for limited edition packaging and the ability to engage with consumers on a more personal level, enhancing brand loyalty.

Understanding these consumer trends allows companies to strategically develop packaging solutions that are not only functional and safe but also attractive and aligned with market expectations. Adapting quickly to these changes is key to maintaining relevance and competitiveness in a fast-paced industry.

FAQ: Key Insights on Innovations and Challenges in Industrial Food Packaging

What are some recent innovations in industrial food packaging?

Recent innovations include the development of biodegradable plastics, edible packaging, smart packaging with built-in sensors, and active packaging that extends shelf life.

What challenges does the food packaging industry face?

Key challenges include environmental concerns, health and safety issues, recycling and waste management complexities, and the high costs associated with implementing new technologies.

How do smart packaging technologies enhance food safety?

Smart packaging technologies such as sensors and QR codes provide real-time information on food conditions, track temperatures, and display freshness levels, significantly improving food safety and traceability.

Why is sustainability important in food packaging?

Sustainability reduces the environmental impact of packaging waste, promotes recycling and reusability, and aligns with consumer preferences for eco-friendly products, driving innovation and regulatory shifts towards greener packaging solutions.

How are consumer preferences influencing food packaging trends?

Consumer demands for convenience, health consciousness, and environmental sustainability are shaping the design and functionality of packaging. This includes developments in easy-to-use formats, materials that maintain food freshness, and eco-friendly packaging options.