Multi-layer

Multi-layer

Multi-layer Packaging

Multi-layer packaging refers to a type of packaging that uses multiple layers of materials to create a single package. Each layer serves a specific purpose, such as providing strength, barrier protection, or printability.

Why Use Multi-layer Packaging?

Multi-layer packaging offers several benefits. It can enhance the shelf life of products by providing better protection against moisture, oxygen, and light. This is especially important for food and pharmaceuticals.

Materials Used in Multi-layer Packaging

Common materials in multi-layer packaging include plastics, paper, and aluminum. Each material is chosen for its unique properties. For example, plastic can offer flexibility, while aluminum provides a strong barrier against contaminants.

Applications of Multi-layer Packaging

Multi-layer packaging is used in various industries. You can find it in food packaging, medical supplies, and even in electronics. Its versatility makes it a popular choice for many products.

Environmental Impact

While multi-layer packaging offers many benefits, it can be challenging to recycle. The different materials need to be separated, which can be a complex process. However, advancements in recycling technology are making it easier to manage.

Conclusion

Multi-layer packaging is a versatile and effective solution for protecting products. Understanding its benefits and challenges can help you make informed decisions about its use.

Blog Posts with the term: Multi-layer

LDPE bags are versatile and durable packaging solutions made from Low-Density Polyethylene, suitable for a wide range of applications including food packaging, medical supplies, retail merchandise, industrial parts, and agricultural products. They offer benefits such as cost efficiency, protective qualities...

The article discusses the significance of yogurt packaging materials in preserving quality, extending shelf life, and marketing. It highlights various types of packaging like glass, plastic, composites, eco-friendly alternatives, and metal containers with their respective properties. Packaging choices for yogurt impact...

The packaging HS code is a ten-digit number essential for international trade, determining tariffs and ensuring compliance with regulations. It's part of the Harmonized System used globally by customs to classify products, where the first six digits are universal and...

Flexible and soft packaging materials are cost-effective, protective solutions that bend to fit contents; they combine substrates like plastics for barrier protection and branding. The industry is shifting towards these lightweight, customizable options due to consumer convenience, sustainability benefits, and...

Perforation in packaging design is a critical element that enhances product breathability, user access, and maintains integrity during transport. It requires careful consideration of material properties and precise techniques to ensure functionality without compromising quality. The role of perforation extends to...

Heat resistant packaging materials are designed to protect contents from high temperatures during transportation or storage, with various forms for different applications and levels of protection. Innovations aim to enhance heat resilience while considering cost-effectiveness and environmental impact. Thermal stability...

The environmental footprint of packaging is a complex issue involving the entire lifecycle from raw material extraction to disposal, with plastics contributing significantly to global warming and pollution. Strategies for reduction include resource efficiency, recycling technology advancements, renewable materials usage,...

Paper cutouts are an accessible art form that allows for intricate, creative expression through simple paper cutting techniques. This craft is inexpensive to start and can be meditative, serving various purposes such as decorations or storytelling across different cultures. The practice...

Plastic barriers are essential in packaging for product protection and preservation, involving polymers with specific properties to prevent permeation of gases, moisture, and chemicals. They come in various forms like films or coatings and must be carefully selected based on...

Understanding packaging box materials is crucial for product presentation, protection, and environmental impact. Material choice affects cost, durability, and sustainability; factors like strength and recyclability must be considered. Paper-based boxes are versatile and range from cardboard to corrugated options with varying...

Sustainable pharmaceutical packaging is under urgent scrutiny due to high CO₂ emissions, regulatory pressure, and the need for safe, recyclable solutions. Cutting-edge recycling technologies—like advanced mechanical sorting, chemical depolymerization, carbon capture polymers, bio-based materials, and digital watermarking—are driving a shift...

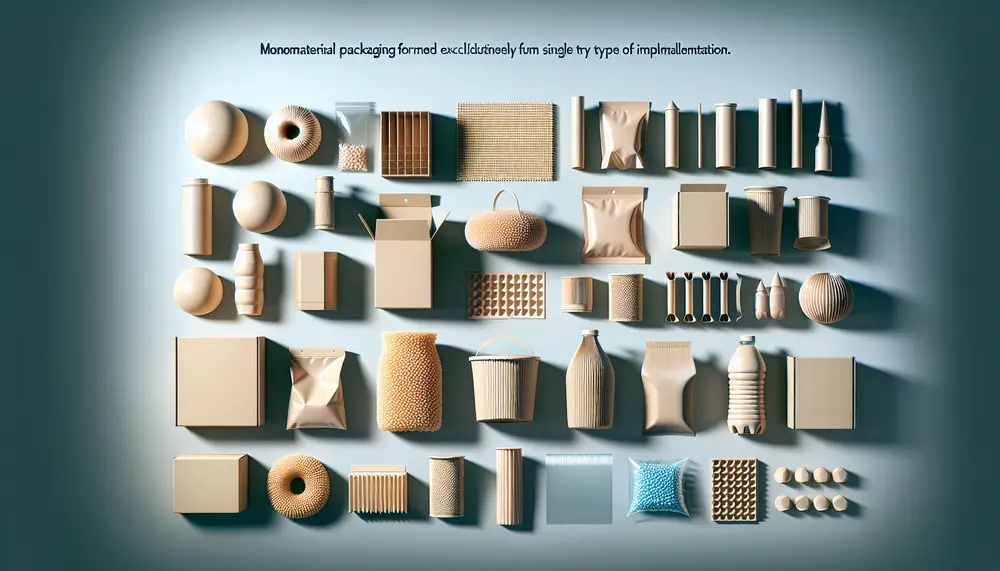

Monomaterial packaging, made from a single material for improved recyclability and production efficiency, faces challenges in maintaining product protection while research continues to develop suitable materials. The shift towards monomaterials aids the environment by reducing carbon footprints and waste, streamlining...

Pharmaceutical packaging boxes are crucial for maintaining the safety, efficacy, and integrity of medications by protecting them from external factors like moisture and contamination, while also providing essential information to healthcare providers and patients. The selection process involves considering material...

Protective packaging for medical devices is essential to ensure their safety, integrity, and sterility during transportation and storage. It involves selecting appropriate materials that can withstand sterilization processes while providing physical protection and maintaining regulatory compliance....

Pharmaceutical packaging waste significantly contributes to global environmental issues, with plastics being a major component that ends up in landfills and oceans, releasing toxins and increasing carbon emissions. Efforts to address this include exploring sustainable materials like bio-based plastics and...