Moisture barrier

Moisture barrier

Moisture Barrier

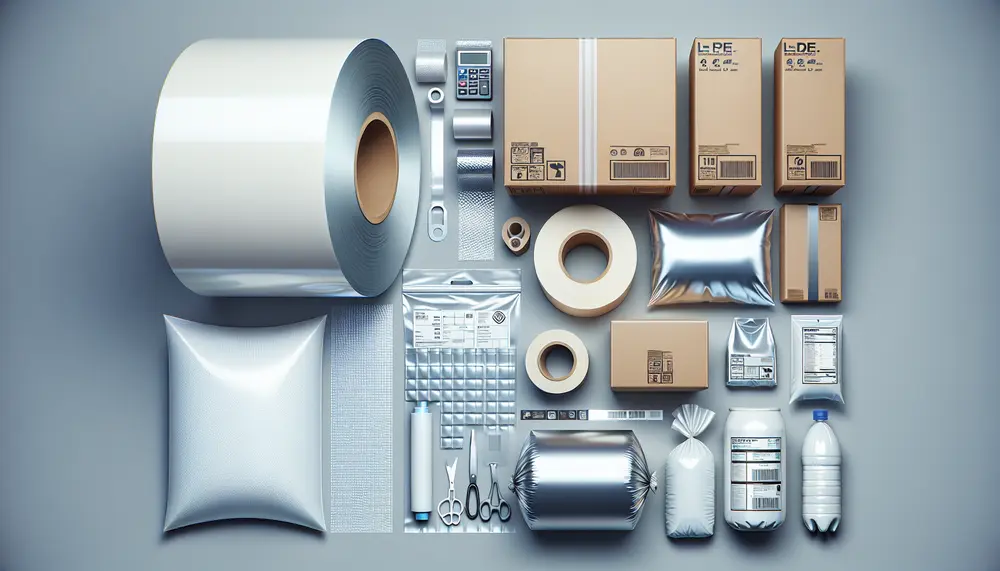

A moisture barrier is a crucial element in packaging. It helps protect products from water and humidity. This is important for items that can be damaged by moisture, such as electronics, food, and pharmaceuticals.

Why Moisture Barriers Matter

Moisture can cause significant damage to many products. For example, it can lead to mold growth in food. In electronics, it can cause short circuits. A moisture barrier prevents these issues by blocking water and humidity.

Types of Moisture Barriers

There are different types of moisture barriers. Common materials include plastic films, aluminum foil, and specialized coatings. Each type has its own advantages. For instance, aluminum foil offers excellent protection but can be more expensive.

Applications of Moisture Barriers

Moisture barriers are used in various industries. In the food industry, they keep products fresh. In pharmaceuticals, they protect medicines from moisture. In electronics, they prevent water damage. This makes them essential in many packaging solutions.

Choosing the Right Moisture Barrier

Selecting the right moisture barrier depends on the product and its needs. Consider factors like the level of moisture protection required and the cost. Consulting with packaging experts can help make the best choice.

Blog Posts with the term: Moisture barrier

This article discusses the evolution and variety of milk packaging materials, highlighting their role in preserving milk's freshness, taste, and nutrition. It covers historical advancements from glass bottles to modern sustainable options, examining each material's benefits and drawbacks for consumers...

Yogurt packaging is essential for maintaining freshness, quality, and safety; it requires an effective barrier against oxygen and light, strength during transportation, regulatory compliance for food contact, and advanced sealing technology. Innovations in the market include smart features like freshness...

Ensuring compliance in pharmaceutical packaging is essential for product integrity, patient safety, and regulatory approval. This article outlines key guidelines from major regulatory bodies like the FDA, EMA, ICH, WHO, and USP that govern material selection, design standards, labeling requirements,...

OPP bags, known for their strength and clarity, are essential in packaging for protection, presentation, and preservation of products. They offer advantages like durability, resealability, cost-effectiveness but have drawbacks such as being non-biodegradable; various types exist to suit different applications. Different...

High-Density Polyethylene (HDPE) is a durable, versatile thermoplastic with a high strength-to-density ratio used in packaging, construction, and various other applications due to its resistance to impact and chemicals. HDPE's production involves polymerization of ethylene gas using different methods that...

Packaging hazards pose risks to product safety during transportation and storage, stemming from physical damage, environmental conditions, and human error; addressing these requires a comprehensive design strategy. Shipping hazards are categorized into shock damage, vibrations, compression forces, and atmospheric conditions;...

Pharmaceutical packaging and design are essential for ensuring medication safety, efficacy, and patient compliance. Effective packaging involves understanding regulatory requirements, material science, and user needs while providing protection, information, identification, convenience, and adherence to treatment plans; it must also comply...

High Density Polyethylene (HDPE) is a crucial material in food packaging due to its durability, chemical resistance, and ability to maintain product integrity under various conditions. It offers advantages such as cost-effectiveness, lightweight nature, customization flexibility, and significant contributions to...

Pharmaceutical packaging is essential for protecting medications from contamination and degradation, providing critical information through labeling, ensuring regulatory compliance, and enhancing user experience with features like child-resistant caps. While it offers benefits such as safe transportation and storage, challenges include...

Packaging technology is crucial for product protection, shelf life extension, and consumer information; it involves material science and design innovation to create sustainable solutions. Cutting-edge materials like bioplastics and smart substances are shaping the industry's future with enhanced functionality and...

Food packaging materials are crucial for protecting food quality and safety, providing consumer information, and ensuring regulatory compliance. The choice of material depends on factors like the type of food, shelf life requirements, storage conditions, and environmental impact. Plastic packaging solutions...

Tablet packaging materials are essential for protecting medication from contamination and damage, with properties tailored to the pharmaceutical product's needs. Secure tablet packaging is vital in maintaining drug potency, ensuring patient safety through tamper evidence, preventing misuse or accidental ingestion,...

Industrial food grade containers are essential for safely storing and transporting various food products, made from materials approved by bodies like the FDA and EU to prevent harmful substance release. These containers enhance product safety, extend shelf life through airtight...

LDPE film is a flexible, transparent thermoplastic used extensively in packaging for its chemical resistance and moisture barrier properties, which are crucial across industries like food, pharmaceuticals, and agriculture. It stands out due to its recyclability and balance of protection,...

Hygiene packaging is crucial for protecting public health by preventing contamination of products like sanitizers and wipes, while also needing to be visually appealing and informative. Effective hygiene packaging features barrier protection, seal integrity, resealable closures, tamper-evidence, ergonomic design, and...