Malleability

Malleability

Malleability in Packaging

Malleability is a key property in packaging materials. It refers to the ability of a material to be shaped or bent without breaking. This is crucial for creating various packaging designs.

Why Malleability Matters

Packaging materials with high malleability can be molded into different shapes. This flexibility allows for innovative packaging solutions. For example, aluminum foil is highly malleable and can wrap around products of various shapes.

Common Malleable Materials

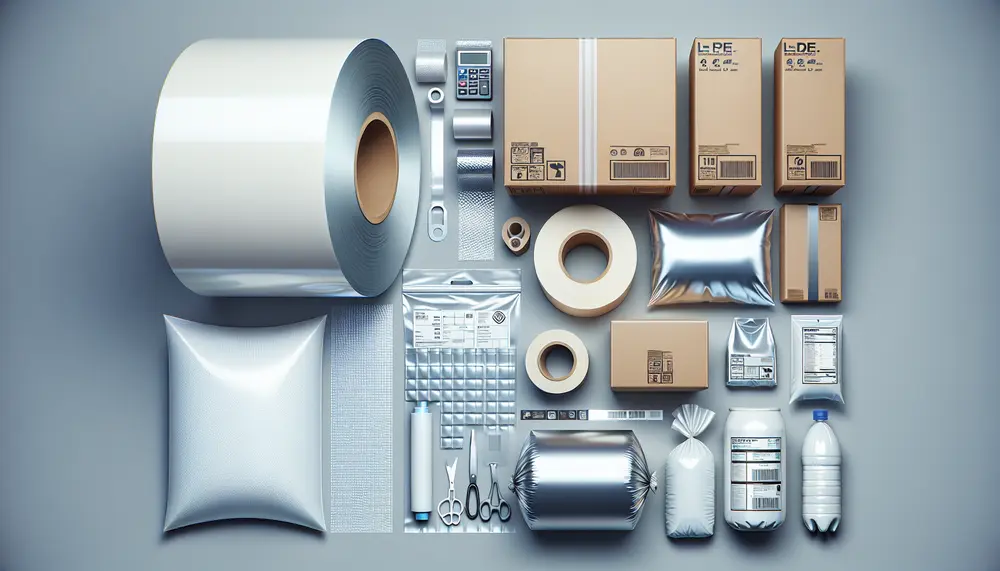

Several materials used in packaging are known for their malleability. These include metals like aluminum and certain plastics. These materials can be easily shaped to fit the needs of different products.

Benefits of Malleable Packaging

Malleable packaging materials offer several benefits. They can protect products better by conforming to their shape. This reduces the risk of damage during transport. Additionally, they allow for creative and functional packaging designs.

Conclusion

Understanding malleability helps in choosing the right packaging materials. It ensures that the packaging can adapt to the product's shape and provide adequate protection. This property is essential for effective and innovative packaging solutions.

Blog Posts with the term: Malleability

Packaging in marketing is a multifaceted tool that influences brand perception and market success, serving not only to protect products but also as a silent salesman through design elements that convey brand values. It enhances visibility, appeal, protection, communication of...

Packaging materials are essential for product protection, information dissemination, and marketing; material selection is based on factors like durability and sustainability. Plastic packaging offers versatility but faces environmental concerns, glass provides purity and recyclability, metal ensures strength and long-term preservation...

LDPE film is a flexible, transparent thermoplastic used extensively in packaging for its chemical resistance and moisture barrier properties, which are crucial across industries like food, pharmaceuticals, and agriculture. It stands out due to its recyclability and balance of protection,...

Radioactive material packaging ensures safety during transport by containing radiation and preventing contamination. It involves understanding radioactivity levels, using shielding materials like lead or concrete, ensuring containment with robust seals, and adhering to strict regulations for different package types designed...

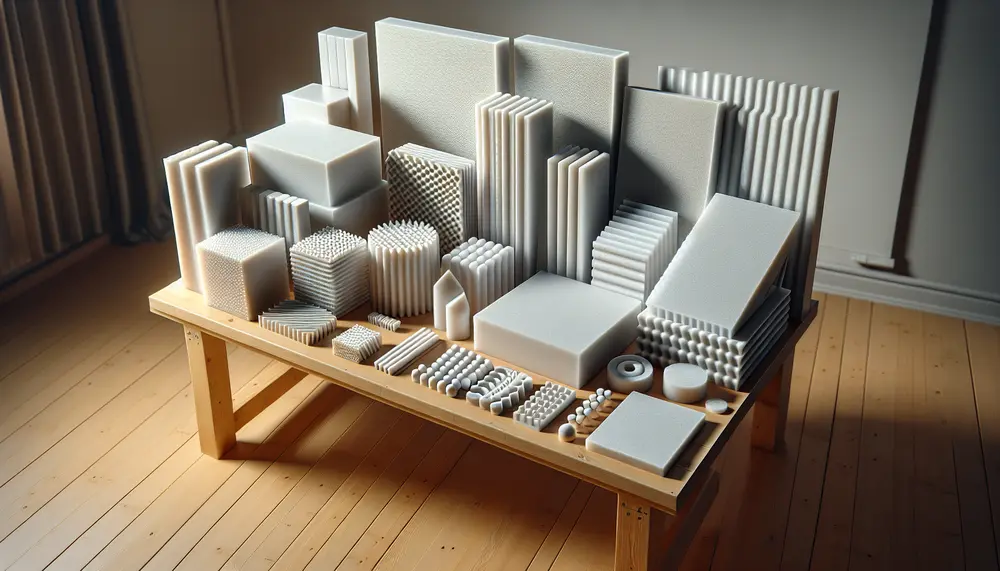

Packaging foam sheets are protective materials, often made from polyethylene or polyurethane foams, used to cushion goods during transport and storage. They offer benefits like shock absorption and customization but have environmental drawbacks due to non-biodegradability and recycling challenges....