Table of Contents:

Understanding Packaging Foam Sheets

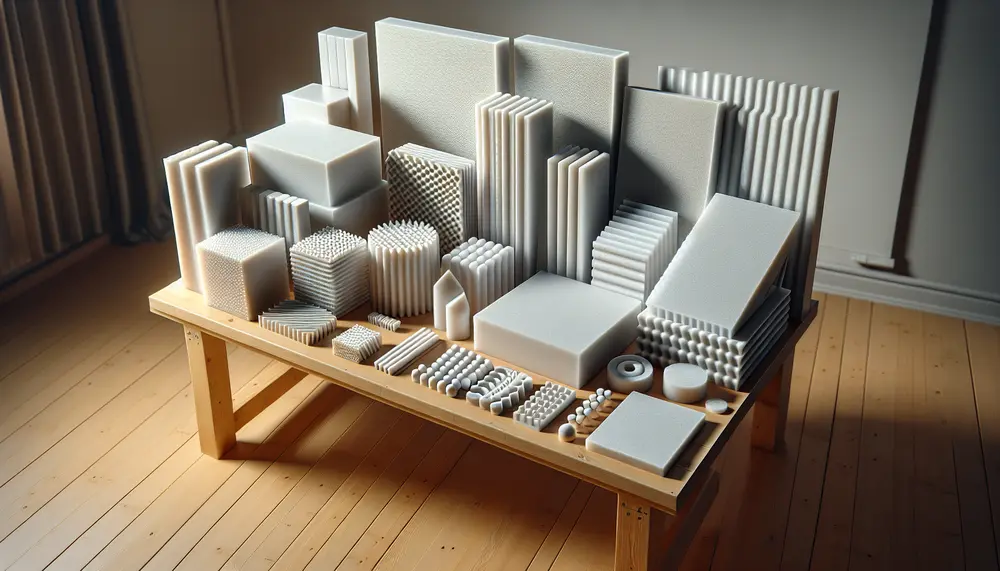

Before delving into the multitude of benefits that packaging foam sheets offer, it's imperative to grasp what they are and their role in safeguarding products. These foam sheets are a type of protective packaging material, designed to provide a cushioning barrier for goods during transportation, handling, and storage. The beauty of this packaging option lies in its simple yet effective structure – typically available in standardized sizes, like the widely-used size of 100cm x 100cm x 1cm, or in custom dimensions tailored to specific needs.

Their composition includes a variety of materials, but most commonly they are produced from polyethylene or polyurethane foams. These materials ensure the foam is lightweight, yet remarkably sturdy. With a standard density of around 20kg/m³ and a pressure hardness of 25 kPa, they strike the perfect balance between softness and resilience, which is crucial in absorbing shocks and vibrations during shipping.

Colors may vary, with the most common being a gentle white-beige or yellowish hue, ensuring the foam does not visually intrude upon packaging aesthetics. Furthermore, adherence to safety standards, particularly the German DIN 4102 B3 regulation for flammability, indicates that these sheets are not only effective but also compliant with stringent safety criteria. This makes them a reliable choice for businesses that prioritize quality and safety in their packaging materials.

Choosing the right foam sheets involves considering the size and vulnerability of the items being packed. Thankfully, you can find multiple sheets conveniently packaged together, often with up to 20 sheets fitting in one package, thus streamlining the procurement process. Additionally, for companies mindful of their carbon footprint, the option for CO2-neutral shipping is another valuable aspect of sourcing these versatile packing sheets.

As we continue exploring the benefits of these foam sheets, it's worth noting that their widespread use across various industries is a testament to their efficiency and durability, proving that they are a cornerstone in modern packaging solutions.

What Are Packaging Foam Sheets?

At their core, packaging foam sheets are engineered to provide a superior level of protection for items during their journey from manufacturer to end-user. An important distinction must be made between the different types available, each serving a different purpose in the packaging industry. Two commonly utilized foams are polyethylene and polyurethane, with each offering unique properties that cater to varied packaging needs.

Polyethylene foam sheets are known for their durability and excellent vibration dampening qualities, making them ideal for long-distance shipping where goods may be subject to consistent movement. On the other hand, polyurethane foam sheets offer higher flexibility and are perfect for sensitive items due to their softer texture, which can absorb impact more readily, ensuring the protection of fragile contents.

Companies seeking packaging solutions often consider the ease of use and adaptability of these materials. Packaging foam sheets are readily cut and shaped, allowing for customization to fit any product shape or size. This ensures that each item, no matter how irregular, can be secured safely within its packaging environment. Moreover, the sheets' usability does not end with padding – they are also often used for insulation purposes, demonstrating their multifunctionality.

With a firm understanding of what packaging foam sheets are and the diversity of their applications, we can better appreciate the various advantages they offer. It is this fundamental knowledge that equips businesses to make informed decisions when selecting the appropriate foam packaging material for their unique shipping and handling requirements.

Comparative Analysis of Foam Sheet Packaging Advantages and Disadvantages

| Pros of Using Packaging Foam Sheets | Cons of Using Packaging Foam Sheets |

|---|---|

| Excellent shock absorption, protecting items during transport. | Not biodegradable, which poses an environmental disposal problem. |

| Lightweight, which can reduce shipping costs. | Can be difficult to recycle in some regions, leading to increased waste. |

| Customizable to fit any shape or size of product securely. | Production of foam sheets may involve harmful chemicals. |

| Reusable for multiple shipping purposes. | Storage of excess materials can require a significant amount of space. |

| Moisture-resistant, providing protection against water damage. | May not be as cost-effective as other packaging materials for large-scale operations. |

Key Advantages of Packaging Foam Sheets

The employment of packaging foam sheets brings with it a host of key advantages that cater to the delicate balance between cost and quality in the packaging industry. These benefits are a primary reason why businesses across various sectors turn to foam sheets as a reliable packaging solution.

- Shock Absorption: The intrinsic properties of foam allow it to absorb and distribute shocks, vibrations, and impacts that occur during shipping and handling, thereby minimizing the risk of damage to the encased products.

- Lightweight: The low weight of foam sheets helps to keep shipping costs down without compromising on the safeguarding of items within. This is especially crucial in an era where transportation costs are perpetually on the rise.

- Moisture Resistance: Certain foam sheets offer resistance to moisture, preventing water damage to goods, which is particularly beneficial for items sensitive to water or those shipped to regions with humid climates.

- Thermal Insulation: The thermal insulation properties make foam sheets an excellent choice for products that require a stable temperature environment, thereby broadening their functional utility beyond mere protective padding.

- Customizable: Customizing foam sheets to fit specific dimensions offers an effective way to accommodate unique product shapes, providing precise protection and eliminating unnecessary waste.

These pivotal benefits underline the practical and economic rationale behind the integration of foam sheets into the protective packaging realm. By capitalizing on their multifaceted advantages, businesses can enhance the safety and integrity of their products throughout the distribution chain.

Protective Qualities of Foam Sheets in Packaging

Delving deeper into the realm of protection, packaging foam sheets offer a robust defense against an array of common hazards that products face when being transported. These protective qualities are integral to maintaining the integrity and appearance of the items they encase, enhancing customer satisfaction and reducing the likelihood of returns due to damage.

The cushioning efficacy of foam packaging materials stands out as the main protective feature. The flexibility of the foam allows it to conform to the shape of the items, eliminating empty spaces that could otherwise permit excessive movement and the potential for harm. By doing so, they assure a snug fit that keeps products in place, even when subjected to abrupt movements or drops.

Additionally, the inherent structure of foam sheets provides a dependable barrier against dents, scratches, and other superficial damages that can occur during the hustle and bustle of the shipping process. This is especially important for delicate surfaces that require extra care to maintain a pristine condition.

Another highlight is the antistatic properties that some foam sheets possess, which makes them indispensable for the safe transportation of electronic components. These specialized antistatic foams prevent the buildup of static electricity that can cause irreparable damage to sensitive electronic goods.

Overall, the protective qualities of foam sheets are a testament to their essential role in safeguarding products during the demanding process of transportation and storage. By focusing on the durability, snug fitting, surface preservation, and specialized needs such as antistatic protection, these materials emerge as a clear choice for ensuring products arrive at their destination as intended.

Versatility and Uses of Packaging Foam Sheets

The versatility of packaging foam sheets is revealed through the wide spectrum of applications they accommodate. The appeal of foam sheets stretches across a broad range of industries due to their adaptability and ease of use, which allow for a plethora of innovative and functional implementations.

Some of the most prominent applications include:

- Electronics packaging, where the non-abrasive and potentially antistatic properties of foam provide safe storage for sensitive devices.

- Medical equipment packaging, which demands a sterile, non-reactive environment alongside the need for premium protection and safety.

- Fragile goods transportation, including glassware and porcelain, where foam sheets act as a buffer to mitigate the risk of breakage.

- Furniture protection, wherein foam sheets are used in the corners and surfaces of items to prevent scrapes and dings during moves or shipping.

- Automotive parts shipment, where the cushioning is essential to keep components secure and free from damage due to vibrations and collisions.

But the use of these foam sheets is not limited to industrial or commercial realms. Many hobbyists and DIY enthusiasts find foam sheets an invaluable asset for crafting projects, custom storage solutions, and even soundproofing. The sheets can be easily tailored by the user to line boxes, create custom inserts, or provide a protective layering for storage of collectibles and other valuable personal items. This convenience of personal adaptation makes foam sheets a go-to for both professional and personal packaging needs.

In essence, the versatility of foam sheets is key to their popularity and widespread use: they provide effective protection and cushioning in a variety of situations, be it for heavy-duty industrial transport or for the meticulous care of personal valuables.

Sustainability and Environmental Impact of Foam Sheets

When considering materials for packaging, the sustainability and environmental impact are increasingly important factors. Foam sheets, often associated with single-use packaging, are under scrutiny for their ecological footprint. Nevertheless, advancements in manufacturing and recycling practices are helping to address these concerns.

One aspect of the sustainability of packaging foam sheets is their durability, which allows for multiple uses before disposal or recycling. This extended life cycle reduces the frequency of replacement, leading to a decrease in material waste. Additionally, the lightweight nature of foam sheets contributes to lower fuel consumption during transport, as they add minimal weight to cargo, enhancing the overall efficiency of shipping and reducing greenhouse gas emissions.

Another promising development is the integration of biodegradable and recycled materials in the production of foam sheets. These eco-friendly alternatives break down more quickly and safely in the environment, helping to reduce the long-term waste associated with packaging materials. Recycling programs and initiatives are also being implemented to reclaim and repurpose used foam, turning what would be waste into valuable resources for new products.

The commitment to CO2-neutral shipping initiatives reflects a growing trend towards environmentally conscious logistics. By offsetting carbon emissions associated with the transportation of foam sheets, companies are taking active steps toward minimizing their carbon footprint and promoting a more sustainable industry practice.

It is clear that the sustainable use and disposal of packaging foam sheets are paramount. By selecting foam sheets that are recyclable, made with eco-friendly materials, or part of carbon offset programs, businesses can help mitigate environmental impacts and forge a path toward a more sustainable future in packaging.

Customization Options for Foam Packaging Solutions

The adaptability of packaging foam sheets extends beyond their broad application scope to include impressive customization options. Tailored foam packaging solutions are vital to meet unique product shapes and sizes, specific protection needs, and brand aesthetic considerations, ensuring a perfect fit for any packaging challenge.

Customization begins with the ability to cut and shape foam sheets, allowing them to snugly wrap around any item, no matter how irregular. This ensures maximum protection by minimizing movement and providing a tailored cushion. It also serves to enhance product presentation, a key aspect for businesses where unboxing is part of the customer experience.

Beyond just size and shape, customization can also involve the specification of foam density and firmness. Different products require different levels of cushioning, and having control over the foam's physical properties means that each item gets just the right amount of protection without unnecessary bulk.

Additional customization options can include the application of adhesives or coatings to the foam sheets for easier assembly and extra protective properties, such as moisture resistance or increased durability. For those keen on branding, foam can also be produced in various colors to match company logos or color schemes, adding a professional touch to the packaging experience.

The resulting custom foam packaging solutions not only serve the practical purpose of protection but also communicate attention to detail and brand commitment to quality, all while addressing the specific demands of the product and the preferences of the business.

Cost-Effectiveness of Using Foam Sheets for Packaging

The use of packaging foam sheets is not only a matter of protecting goods effectively but also of doing so in a cost-effective manner. The economic advantages of this packaging choice are significant, providing ample justification for their popularity among businesses looking to optimize expenses.

One of the primary factors contributing to the cost-effectiveness of foam sheets is their material efficiency. Despite providing excellent cushioning and protection, foam sheets are thin and light, which means they do not add excessive weight to packages, thus keeping shipping costs low. This is particularly beneficial in an industry where transportation costs can have a substantial impact on the bottom line.

Additionally, foam sheets are easy to handle and store, reducing labor costs associated with packing and unpacking. Their malleability means they can be quickly shaped or stripped into the desired sizes with minimal effort, streamlining the packing process.

Being able to fit multiple foam sheets – sometimes up to 20 in a single package – maximizes space efficiency, both in terms of storage and shipping. The compact bundling translates into savings by decreasing the number of packages handled and sent, reducing both physical space requirements and shipping frequency.

Moreover, the longevity of foam sheets, with their ability to be reused multiple times before exhibiting wear and tear, extends the value gained from each sheet, further amplifying cost savings over time.

Overall, the convergence of material efficiency, ease of use, space optimization, and durability makes foam sheets a financially savvy option for businesses. By minimizing shipping and handling costs, as well as reducing waste, foam sheets provide a fiscally responsible solution that aligns with the economic goals of cost-conscious organizations.

Comparing Foam Sheets to Other Packaging Materials

When selecting the ideal packaging material, businesses often weigh the attributes of packaging foam sheets against other options such as bubble wrap, packing peanuts, and rigid foam inserts. Understanding the comparative advantages and limitations of these materials is essential for making informed decisions that align with the specific needs of each product and shipping scenario.

Bubble wrap, a common alternative, provides a certain level of impact protection and is particularly user-friendly. However, foam sheets often overshadow bubble wrap in terms of custom shape capabilities and more consistent protection, especially for products with sharp edges that might puncture bubble wrap.

Packing peanuts, while useful for filling voids within boxes, can be messy and less environmentally friendly, unless they are made from biodegradable substances. Foam sheets eliminate the potential for such mess and are easier to apply and remove without leaving residues, offering a cleaner, more professional packaging experience.

Rigid foam inserts provide excellent security for products but lack the flexibility and cost-effectiveness of foam sheets, which can be crucial for businesses looking to reduce packaging costs while still providing ample protection. Foam sheets, in contrast, blend robust protection with the ability to conform to a variety of shapes and sizes, offering a balance of efficiency and performance.

In summary, while other packaging materials have their advantages, foam sheets stand out due to their versatility and ability to be tailored to specific needs, whether in terms of shape, protection level, or cost considerations. This adaptability makes them a favored choice among various packaging options on the market.

Safety Standards: Complying with DIN 4102 B3

One of the critical aspects of selecting packaging materials, especially within industries where safety is non-negotiable, is ensuring compliance with regulatory safety standards. Packaging foam sheets, like many other products, must adhere to specific guidelines to be considered safe for use. The German DIN 4102 B3 standard is one such regulation that assesses the flammability of construction materials, including packaging foams.

Meeting the DIN 4102 B3 standard means that the foam sheets have been tested and classified as compliant with the fire safety requirements set out in this specification. This involves evaluating the material's reaction to fire and its contribution to the spread of flames. The certification assures businesses and consumers that the foam packaging being used is not a fire hazard, providing an additional layer of safety during the storage and transportation of goods.

Manufacturers of foam sheets who achieve this certification must undergo rigorous testing and quality control processes. These stringent checks ensure that the foam not only provides excellent protective cushioning but also contributes to safer work and shipping environments. For businesses, using DIN 4102 B3 compliant foam is part of due diligence and risk management best practices, showing a commitment to high safety standards.

As a critical part of the safety compliance checklist, the utilization of foam sheets that conform to recognized fire safety norms highlights a company’s dedication to delivering safe, reliable packaging solutions. The choice to adhere to the DIN 4102 B3 standard can also enhance a brand's reputation as a conscientious and safety-focused organization.

Selecting the Right Density and Hardness in Foam Sheets

Selecting the optimal density and hardness for foam sheets is a crucial factor in tailoring packaging solutions that are both effective and efficient. These two attributes define the structural characteristics of the foam and largely dictate its suitability for various packaging applications.

The density of foam, often measured in kilograms per cubic meter (kg/m³), indicates the amount of material packed into a given volume and impacts the foam’s overall durability and support capacity. Higher densities typically suggest a more robust material that can endure heavier loads and resist compression over time, making it suitable for protecting weightier products.

Conversely, hardness, quantified in kilopascals (kPa), reflects the foam's resistance to pressure and its ability to return to its original shape after compression. The hardness level chosen will affect how the foam cushions and absorbs impacts. Firmer foams with higher kPa values offer sturdier support, while softer foams with lower values provide more give, accommodating delicate or irregularly shaped objects.

It is the synergy between the chosen density and hardness of foam sheets that culminates in a packaging material capable of delivering the desired level of protection. Businesses must consider the nature of the items being packaged—their weight, fragility, and shape—to determine the most appropriate foam specifications.

By carefully considering and selecting the correct combination of density and hardness, businesses can ensure that their products are bestowed with an optimal protective environment, ultimately minimizing damage during transit and storage while avoiding unnecessary material usage and costs.

Maximizing Efficiency with Foam Sheet Dimensions

The efficiency of packaging can be significantly influenced by the chosen dimensions of packaging foam sheets. Accurate sizing contributes to not only better protection for the product but also a reduction in material waste and cost savings.

Standard sizes, such as foam sheets measuring 100cm x 100cm, provide a practical starting point and can accommodate a wide range of products. However, to truly maximize efficiency, considering the precise dimensions needed for specific items is essential. Custom-cut sheets that fit the product exactly eliminate the need for additional cuts or excess material, leading to a cleaner, more streamlined packaging process.

In scenarios where multiple products are being shipped together, optimizing the size and thickness of foam sheets can mean the difference between needing one package or several. Efficiently packed items that make the most of the available space can significantly reduce shipping volumes and costs.

The ability to fit up to 20 sheets in one package exemplifies the practicality of foam sheets in logistical planning. This level of efficiency optimizes not only the individual package's content but also the overall packaging operation, from the storage of materials to the distribution of final products.

In conclusion, when businesses take the time to assess and select the appropriate foam sheet dimensions for their packaging needs, they gain the benefit of enhanced product protection and a more cost-effective, eco-friendly approach to shipping and handling.

The Convenience of Packaging Foam Sheets for Businesses

The use of packaging foam sheets is considered highly convenient for businesses of all sizes, creating a smooth and efficient workflow from the moment a product is packed until it reaches its destination. This convenience is particularly significant when considering the logistical and operational benefits that foam packaging brings to the table.

One of the standout conveniences is the material's ease of handling and storage. Foam sheets are lightweight and flexible, making them simple to maneuver and place around items. They do not require specialized equipment or extensive training to use effectively, allowing for quick and uncomplicated packaging even for novice staff members.

Furthermore, the streamlined nature of foam sheets enables businesses to minimize packing time. With less time spent on wrapping and securing, companies can process more shipments in the same time frame, increasing their throughput and potential for scaling operations.

Storage is also simplified as foam sheets can be conveniently stacked or rolled, occupying minimal space in inventory. Their compact form before use translates to reduced warehousing costs and a tidy, organized packing area that contributes to a more efficient working environment.

In addition, businesses that rely on a constant supply of packaging material will appreciate the availability of foam sheets in larger quantities within single shipments, such as the capacity to fit up to 20 sheets per package. This not only ensures that they have enough material on hand to meet demand but also aids in planning and budgeting for packaging needs.

Overall, the convenience offered by foam sheets—from the ease of use to the efficiency in packing and the advantages in storage and procurement—makes them an invaluable resource for businesses looking to optimize their packaging operations.

Ensuring Product Safety During Transit with Foam Sheets

Ensuring product safety during transit is a primary concern for any business that ships goods. Packaging foam sheets play a critical role in creating a secure environment that guards against the risks of transport, which can include rough handling, collisions, and pressure changes.

One significant advantage of foam sheets is their shock-absorbing properties. When items are cushioned by foam, the material acts to disperse the energy from impacts that occur during shipping, thereby reducing the likelihood of damage. This is especially important for fragile or delicate items that require an additional level of care.

Moreover, the conformability of foam allows it to mold around products of various shapes, creating a custom-fit protective layer. This tailored cushioning minimizes movement within the packaging, further limiting the potential for wear or breakage during the journey.

The versatility of foam sheets also extends to their capability to be layered and combined with other packaging materials for enhanced protection. Whether used as a single sheet for light cushioning or in multiple layers for added security, foam sheets provide a flexible solution adaptable to the specific protection needs of each shipment.

Addressing the safety of products during transit not only affects the direct cost associated with damaged goods but also impacts customer satisfaction and a company's reputation. By utilizing foam sheets as part of a comprehensive packing strategy, businesses can achieve peace of mind, knowing that their products are well-protected until they reach their final destination.

The Future of Packaging: Innovations in Foam Technology

The packaging industry is continually evolving, with innovations in foam technology paving the way for more efficient and sustainable solutions. As businesses and consumers alike grow more environmentally conscious, the demand for advancements that reduce the ecological impact of packaging materials is stronger than ever.

One of the most exciting developments in this field is the creation of biodegradable and recycled foams. These materials promise to alleviate environmental concerns by providing foam sheets that can break down more naturally in the environment or can be recycled more effectively, closing the loop on production and consumption cycles.

Moreover, recent trends point to the use of smart technologies in foam production, such as incorporating sensors within foam sheets that can monitor environmental conditions like temperature and humidity. This innovation is particularly beneficial for the shipping of sensitive items where maintaining specific conditions is critical for product integrity.

Another innovative approach is the customization of foam materials at the molecular level, enabling the production of foams with precisely engineered properties tailored to specific applications. This could mean foams with higher resilience, improved fire resistance, or even enhanced acoustic insulation properties, broadening their use beyond traditional packaging.

As the future of packaging unfolds, it becomes clear that foam technology will continue to adapt and advance in response to market demands and environmental challenges. By embracing and investing in these innovations, businesses can secure a competitive advantage and demonstrate their commitment to responsible packaging practices.

Conclusion: Why Choose Packaging Foam Sheets for Your Needs

In summarizing the comprehensive benefits of packaging foam sheets, it's clear why they are a preferred choice for businesses looking to protect their products effectively and efficiently. The advantages discussed demonstrate how foam sheets stand above other packaging options, offering unparalleled protection, versatility, and cost savings.

Foam sheets’ protective qualities, including their ability to absorb shock and resist moisture, make them an ideal safeguard for goods during transit. Their versatility not only allows for their use in a range of industries but also provides customization options to suit any product’s unique requirements.

Moreover, the focus on sustainability is evident in the push toward eco-friendly materials and practices, ensuring that the use of foam sheets aligns with the evolving standards of environmental responsibility. Businesses aware of their ecological footprint will find foam sheets to be a step in the right direction, marrying protection with sustainability.

Finally, the sheer convenience of foam sheets makes them a smart logistical choice. Their ease of use, storage, and ability to be customized in size and density, along with the cost savings associated with their lightweight nature, optimize business operations from packaging to shipping.

Choosing packaging foam sheets is ultimately an investment in the integrity of your products and the satisfaction of your customers. With ongoing innovations in foam technology, businesses can look forward to even more advanced and sustainable packaging solutions in the future.

FAQ on Advantages of Packaging Foam Sheets

Why should businesses use packaging foam sheets?

Packaging foam sheets provide excellent shock absorption, protecting items during transport, and are lightweight, which helps reduce shipping costs. They can be customized to fit any product securely, are moisture-resistant, and offer the convenience of CO2-neutral shipping options.

How do packaging foam sheets enhance product safety during transit?

The foam's shock-absorbing properties disperse energy from impacts, while its conformability allows for a tailored fit around products to minimize movement and potential damage within the packaging.

Are foam sheets customizable for different packaging needs?

Yes, foam sheets can be easily cut and shaped to fit specific dimensions, providing precise protection and eliminating unnecessary waste. They can be tailored to accommodate unique product shapes, which maximizes both protection and presentation.

What are the sustainability features of packaging foam sheets?

Packaging foam sheets are durable, allowing for reuse before recycling. Many are also CO2-neutrally shipped, and advancements in eco-friendly materials and practices are enhancing their sustainability. Biodegradable and recycled foams are also becoming available.

How cost-effective are foam sheets compared to other packaging materials?

Foam sheets are a cost-effective packaging solution due to their material efficiency, reducing additional weight and thus transportation costs. They're easy to handle and store, which decreases labor costs, and their durability extends their lifecycle, further lowering long-term expenses.