Adhesive

Adhesive

Adhesive in Packaging

An adhesive is a substance used to bond two surfaces together. In the context of packaging, adhesives play a crucial role in ensuring that packages remain sealed and intact during transport and storage.

Types of Adhesives

There are various types of adhesives used in packaging, including:

- Hot Melt Adhesives: These are applied in a molten state and solidify upon cooling.

- Pressure-Sensitive Adhesives: These stick to surfaces when pressure is applied.

- Water-Based Adhesives: These use water as a carrier and set when the water evaporates.

Applications of Adhesives in Packaging

Adhesives are used in many packaging applications, such as:

- Sealing Boxes: Ensuring that boxes remain closed during shipping.

- Labeling: Attaching labels to packages for identification.

- Product Assembly: Holding different parts of a package together.

Benefits of Using Adhesives

Using adhesives in packaging offers several benefits:

- Strong Bond: Provides a secure seal that keeps contents safe.

- Versatility: Suitable for various materials like paper, plastic, and metal.

- Efficiency: Quick application speeds up the packaging process.

Conclusion

Adhesives are essential in the packaging industry. They ensure packages are secure, labels stay in place, and products are well-assembled. Understanding the different types and applications of adhesives can help you choose the right one for your packaging needs.

Blog Posts with the term: Adhesive

Unique packaging designs enhance gift boxes by creating memorable unboxing experiences and reflecting the giver's care. Personal touches, eco-friendly materials, and innovative design elements can elevate both personal gifts and brand identity. Creative packaging for gifts makes a strong first impression,...

This article discusses the evolution and variety of milk packaging materials, highlighting their role in preserving milk's freshness, taste, and nutrition. It covers historical advancements from glass bottles to modern sustainable options, examining each material's benefits and drawbacks for consumers...

This guide offers step-by-step instructions for creative gift wrapping techniques like zig-zag folds, pocket methods, and origami accents to elevate your presents. It also provides festive packaging ideas using layered textures, custom tags, personalized elements, unique color palettes, and reusable...

Ensuring compliance in pharmaceutical packaging is essential for product integrity, patient safety, and regulatory approval. This article outlines key guidelines from major regulatory bodies like the FDA, EMA, ICH, WHO, and USP that govern material selection, design standards, labeling requirements,...

Understanding sustainable packaging is vital for businesses to minimize environmental impact and meet consumer demands, focusing on eco-friendly materials and practices. Key concepts include life cycle assessment, recyclability, and the circular economy, which guide companies in selecting suitable materials while...

Flexible and soft packaging materials are cost-effective, protective solutions that bend to fit contents; they combine substrates like plastics for barrier protection and branding. The industry is shifting towards these lightweight, customizable options due to consumer convenience, sustainability benefits, and...

OPP bags, known for their strength and clarity, are essential in packaging for protection, presentation, and preservation of products. They offer advantages like durability, resealability, cost-effectiveness but have drawbacks such as being non-biodegradable; various types exist to suit different applications. Different...

The guide explains the significance of MOSH (Mineral Oil Saturated Hydrocarbons) and MOAH (Mineral Oil Aromatic Hydrocarbons) in food packaging, highlighting their potential health risks due to migration into food. It emphasizes the need for ongoing research, industry regulation, and...

EU packaging regulations require businesses to minimize waste, enhance recyclability, and reduce hazardous substances. Compliance with the Packaging and Packaging Waste Directive is essential for market access in the EU....

Zip packaging, also known as zip-lock or resealable packaging, is a versatile and functional form of product packing that maintains the freshness and quality of products. It plays a crucial role in ensuring product safety across various industries by preventing...

Duplex paper is a two-layered packaging material known for its printability and structural integrity, widely used across industries due to its visual appeal and sturdiness. It's also eco-friendly, being recyclable and often made from sustainable sources. Advancements in duplex paper manufacturing...

Pharmaceutical packaging for export requires strict adherence to international regulations set by global regulatory bodies like WHO, ICH, EMA, FDA, and PMDA to ensure safety and quality. Key regulations include Good Manufacturing Practice (GMP), ISO standards, serialization systems, labeling requirements,...

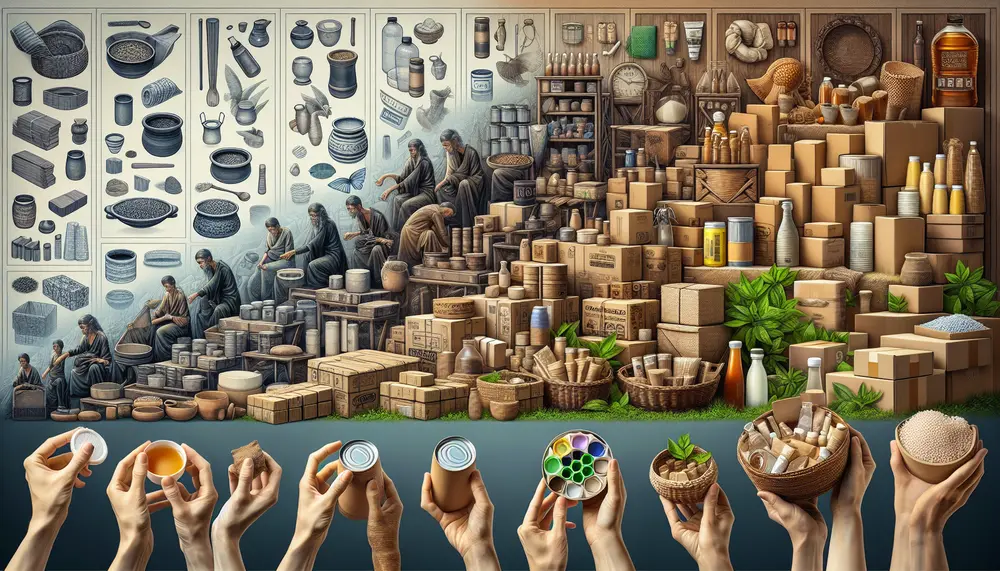

The article traces the history of packaging from natural materials used by early humans to innovations like wooden containers and paper, highlighting its role in trade and commerce. It details China's invention of paper as a transformative material for packaging...

EO sterilization is a vital low-temperature method for medical devices, requiring packaging that allows gas penetration and maintains sterility. Packaging materials like PE, PP, polystyrene, nylon, PET, and multilayer laminates are compatible with EO but must be designed to ensure...

Packaging and packing are distinct processes in goods transportation; packaging focuses on product protection and presentation, involving design for brand identity, while packing is about enclosing products for safe distribution. Primary, secondary, and tertiary packaging provide different levels of protection...