Table of Contents:

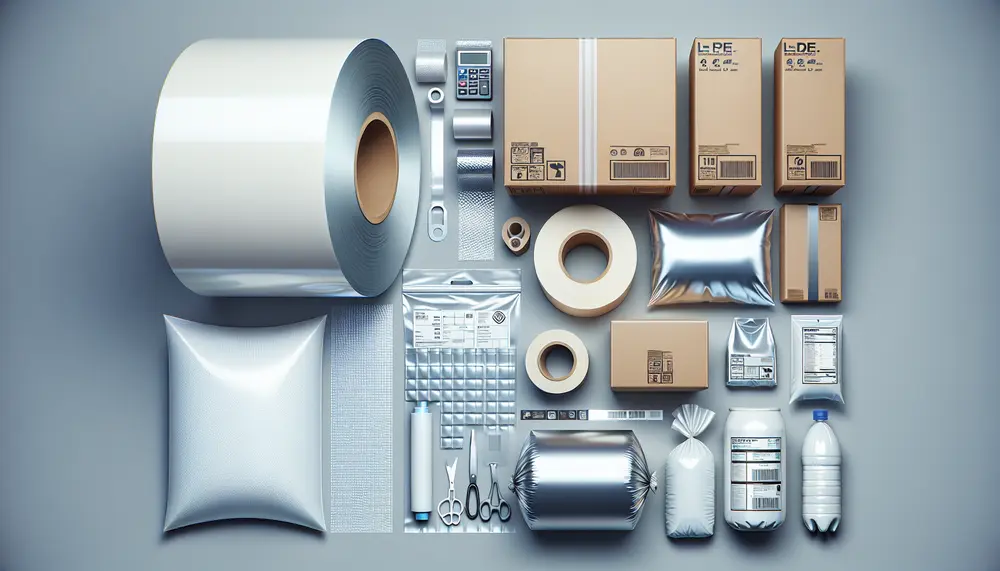

Understanding LDPE Film and Its Role in Packaging

Low Density Polyethylene (LDPE) film is a thermoplastic made from the monomer ethylene. It's a staple in the packaging industry due to its remarkable balance of ease of processing, flexibility, and transparency, which imparts a high level of practicality to various packaging solutions. LDPE film's flexibility allows it to conform to the shape of products, providing protection and stability for transportation while also giving products a neat, polished look on shelves.

One of the standout features of LDPE film is its excellent chemical resistance, which makes it a favorable choice for packaging products that could be compromised by reactive substances. This is particularly important in industries where packaging integrity can affect the safety and longevity of the product, such as in food, pharmaceuticals, and agriculture.

Moreover, LDPE film exhibits strong moisture barrier properties. This is crucial for preserving the freshness and quality of perishable goods, making it a popular option for food applications, including freezer and snack products. The combination of its properties such as its resilience and durability result in a material that is both versatile and reliable as a packaging medium.

In addition to its functional benefits, LDPE film also presents a clear environmental advantage as it is recyclable. Packaging solutions that prioritize sustainability are increasingly sought-after, and the ability to recycle LDPE film can significantly reduce the ecological footprint of packaging processes.

Understanding the characteristics and benefits of LDPE film aids businesses in making informed decisions when selecting packaging materials. It also ensures consumers receive their products in the best possible condition. LDPE film's role in packaging is not only about wrapping or containing a product but also about maintaining its integrity, prolonging its shelf life, and reducing waste through its lifecycle.

Key Properties of LDPE Film That Enhance Packaging

The packaging industry is in a constant search for materials that strike the perfect balance between protection, cost, and sustainability. LDPE film is favored for its key properties that meet these needs. To understand what sets LDPE film apart, let's consider the specific attributes that make it particularly useful in packaging.

LDPE film's high degree of flexibility extends beyond physical bending and twisting. It translates into adaptability in packaging design, allowing for customization in shape, size, and features such as easy-open perforations or resealable closures. This customization potential ensures that products of all types can be securely and practically packaged.

Another significant property is optical clarity. Transparency in packaging is not just aesthetically pleasing, allowing consumers to see the product inside, but it also provides a quick quality check, reducing the need for additional opening or handling, thus preserving hygiene and integrity.

Regarding durability, LDPE film’s toughness protects against tears and punctures during shipping and handling. This robust nature ensures products arrive at their destination in the condition intended without the need for excessive packaging layers.

The ability of LDPE film to be heat-sealed fosters secure packaging. This thermoplastic feature allows for tight and tamper-evident seals, which is essential for food safety and maintaining freshness.

Lastly, the cost-efficiency of LDPE film should not be understated. Its relatively low material and production costs make it an economical option for businesses without sacrificing quality or functionality in packaging. Businesses can manage expenses while still offering secure, attractive packaging to their customers.

To summarize, the key properties of LDPE film such as flexibility, clarity, toughness, sealability, and cost-efficiency, directly enhance its functionality as a packaging material. These attributes enable LDPE film to address the diverse needs of modern packaging, from consumer appeal to logistical requirements.

Applications of LDPE Film in Various Industries

LDPE film's versatility allows it to serve a multitude of industries, each with its own set of requirements and regulations. The film's adaptable nature ensures that it can be tailored to fit the unique demands of different products and packaging designs. Here’s an overview of how LDPE film is applied across various sectors:

- In the healthcare industry, LDPE film is used to package medical devices and supplies. Its chemical resistance and ability to maintain sterility make it a go-to choice for ensuring medical products remain uncontaminated.

- LDPE film plays a critical role in the food and beverage sector. It is commonly used for packaging items such as meats, fruits, veggies, and bakery products due to its moisture barrier and food safety properties.

- The agricultural industry benefits from LDPE film to safeguard products like fertilizers and seeds, guarding them against moisture and pests while maintaining their quality.

- In the realm of textiles and apparel, garments are often shipped and stored in LDPE bags to protect them from dust, dirt, and moisture, ensuring they stay fresh from production line to closet.

- LDPE film also finds application in industrial and construction settings as it can cover and protect materials during manufacturing or on-site work, defending surfaces from damage and contamination.

These examples are just a snapshot of LDPE film's widespread use. Its basic characteristics can be tweaked, such as its thickness or texture, to suit the particular protective needs of a product, emphasizing the film’s adaptability. Whether it's safeguarding perishable items from spoilage or ensuring robust protection for manufacturing components, LDPE film provides solutions that are both effective and efficient for various industry applications.

Comparing LDPE Film to Other Packaging Materials

When selecting the most suitable packaging material for a particular application, comparing LDPE film to other commonly used materials highlights its distinctive qualities. Other materials might include High Density Polyethylene (HDPE), Polypropylene (PP), and Polyethylene Terephthalate (PET), each with their own set of attributes and uses within the packaging industry.

| Material | Flexibility | Durability | Clarity | Moisture Barrier | Cost-Effectiveness |

|---|---|---|---|---|---|

| LDPE | High | Good | High | Excellent | Very Good |

| HDPE | Lower | Very Good | Lower | Good | Good |

| PP | Good | Very Good | Good | Good | Good |

| PET | Low | Excellent | Excellent | Excellent | Good |

While HDPE is known for its stiffness and strength, it does not match the flexibility of LDPE, which can be essential for packaging that requires a softer touch or greater malleability. PP, on the other hand, offers similar durability but generally lacks the same level of moisture barrier as LDPE, which can be critical for food safety and preservation.

PET is renowned for its clarity and strength, making it an ideal solution for rigid packaging like bottles. However, it doesn't provide the same ease of sealing and flexibility for packaging that may need to conform or bend around products without breaking.

Cost is another important factor, and here, LDPE typically has an advantage due to its simplicity in manufacture and efficiency in production. LDPE film’s balance of properties coupled with its cost-effectiveness make it an attractive option for a broad range of packaging needs.

Ultimately, the choice of packaging material often depends on the specific requirements of the product being packaged. Each material has its place in the market, and LDPE film stands out for applications that require a blend of flexibility, clarity, and superior moisture barrier properties at an efficient cost.

The Manufacturing Process of LDPE Film

The process of manufacturing LDPE film is a meticulous one that involves several stages, each crucial to ensuring the film's quality and characteristics suitable for its wide-ranging applications. The fundamental stages can be broadly summarized into the following:

- Extrusion: The journey of LDPE film starts in the extruder, where the LDPE resin pellets are heated to a molten state and then pushed through a circular die to form a thin, continuous tube of plastic.

- Blowing: The molten tube is then inflated with air, creating a bubble. This bubble is carefully cooled as it is pulled upwards by rollers, causing the plastic to slowly solidify while also expanding to the desired size.

- Cooling: After the film is blown, it goes through a cooling process. Air rings blow cool air onto the film bubble, solidifying the LDPE into a stable film structure.

- Flattening: Once cooled, the film bubble is collapsed into a flat double layer by flattening frames, transforming the tubular shape into lay-flat film.

- Winding: The flat film is then wound onto large rolls. These rolls can be further processed depending on the intended use, such as cutting them to size or treating them to alter surface characteristics.

- Finishing: Finally, the film may undergo finishing processes such as printing, lamination, or the addition of adhesives or coatings to confer additional properties such as improved printability or sealability.

This manufacturing process can be highly customized with adjustments made to the extrusion conditions, cooling rates, and finishing processes to achieve films with specific thicknesses, strengths, shrink properties, and other attributes. The adaptability of this process allows manufacturers to cater to the varied needs of different industries and packaging requirements.

By understanding the manufacturing steps for LDPE film, one can appreciate the engineering behind a material that is so common yet critical in our everyday lives. This also highlights the potential for innovation within the production process to create films with targeted properties for new and evolving uses.

Product Advantages of Using LDPE Film in Packaging

Choosing LDPE film for packaging encompasses a variety of advantages that benefit both the manufacturer and the end user. These product advantages are critical in a market that values both performance and cost-effectiveness.

The customization aspect of LDPE film is a significant advantage, as producers can specify the thickness range—from as thin as 3 mil to up to 30 mil. This allows for precise control over the protective qualities required for different products. The availability of various colors like green, natural, black, and clear adds to the aesthetic and functional customization, enabling greater product visibility or ultraviolet light protection when necessary.

LDPE film's ease of processing is another upside. It is readily weldable using heat sealing techniques, making it a convenient option for manufacturers to create airtight and moisture-proof packages efficiently. Additionally, the film can be easily printed on, allowing for brand customization and necessary labeling, which are vital for consumer engagement and regulatory compliance.

Strength and toughness are also paramount when discussing the advantages of LDPE film. These characteristics provide a safeguard against punctures and tears that might occur during transportation or handling, ensuring the products within remain intact and contamination-free.

Lastly, the recyclable nature of LDPE film underscores its environmental appeal. The ability to recycle the material aligns with growing consumer expectations for sustainable practices. It's also in harmony with businesses aiming to minimize their environmental impact while still providing high-quality packaging solutions.

The balance of these advantages—coupled with cost efficiency—makes LDPE film an attractive option in the packaging industry. Its role is instrumental in maintaining product integrity, brand identity, and environmental sustainability, all while facilitating smooth manufacturing processes.

Customization and Availability of LDPE Film Options

Customization is at the heart of LDPE film's viability as a packaging solution, meeting a broad spectrum of functional and branding requirements. Clients can tap into a range of customization options that LDPE film manufacturers like Primex Plastics and Bostik provide. This versatility is what allows businesses to differentiate themselves in crowded marketplaces and tailor their packaging to the specific needs of their products.

One of the most significant customization options is the selection of film thickness. LDPE film can be produced in variations from 3 mil to 30 mil, allowing for targeted strength and flexibility. Thicker films offer more protection and are ideal for heavier or more rugged items, while thinner films might be chosen for their pliability and lighter weight.

Color customization plays a crucial role in product presentation and utility of the LDPE film. The spectrum of available colors includes green, natural, black, and transparent options, providing opportunities for companies to align their packaging with brand aesthetics or making the product itself more visible to the consumer when clear film is used.

The suitability of LDPE film for various printing techniques is another customization advantage. Businesses can print logos, instructions, branding elements, or regulatory information directly onto the film, which enhances brand visibility and meets labeling requirements.

To cater to specialized applications, there are LDPE film types with additional properties like UV resistance, anti-static, and slip agents. This degree of customization ensures that whether a business needs packaging for sensitive electronics or perishable goods, there's an LDPE film fit for the purpose.

In terms of availability, LDPE film manufacturers often provide options like 'Request a Sample' and 'Request a Quote'. These services assure clients can evaluate the film quality and work with suppliers to discuss customization specifics before making larger investment decisions.

Through the blend of customizable features and diverse material options, LDPE film presents itself as a highly adaptable packaging material designed to meet the needs of an extensive array of products and industries.

LDPE Film Processing Techniques for Optimal Use

Maximizing the efficacy of LDPE film in packaging relies on implementing the right processing techniques. These methods are tailored to enhance the film's inherent properties, ensuring optimal performance for its intended use. Let's delve into some of the principal processing techniques that bring out the best in LDPE film.

Heat welding or heat sealing is a critical processing step for LDPE film, allowing the creation of air-tight and moisture-resistant closures. This technique is essential for packaging that requires a high degree of protection against external contaminants, especially for food and medical products.

Printing on LDPE film involves specific methods suited to its texture and properties to ensure that inks adhere correctly and maintain durability. Whether for brand identification, instructional content, or legal compliance, printing must be executed with precision to remain legible and resist wear throughout the product's lifecycle.

Coating and lamination applications are sometimes employed to lend additional features to the LDPE film, such as enhancing its barrier qualities or adding a matte or glossy finish. These processes can also further augment the film's resistance to punctures or tears.

In the context of recycling and sustainability, LDPE film may undergo specialized treatments to facilitate compatibility with other polymers during the recycling process, or to improve its biodegradability without compromising functionality during use.

Advancements in material science and manufacturing technology continue to introduce new processing techniques that expand the uses and capabilities of LDPE film. Each technique is an opportunity to optimize the film for specialized requirements, making it an even more integral part of the packaging industry.

By utilizing these processing techniques, manufacturers are able to enhance LDPE film’s natural qualities, making it an even more attractive option for businesses looking for versatile and reliable packaging solutions.

Recycling and Environmental Aspects of LDPE Film

The conversation around the environmental impact of packaging materials is becoming increasingly relevant. LDPE film is no exception and is often scrutinized for its recyclability and overall ecological footprint. However, LDPE film does bring to the table several positive recycling and environmental aspects that are important to acknowledge.

Recycling is a key element in reducing the environmental impact of packaging materials. LDPE film is fully recyclable, which means it can be reprocessed and used in the production of new materials. This reduces the need for virgin materials, conserving resources, and lowering the carbon footprint associated with the production of new plastics.

Many regions have infrastructure in place to collect and process LDPE film, allowing it to be diverted from the waste stream. When recycled, LDPE can find new life in products such as trash can liners, landscape timber, and even new packaging materials, demonstrating a closed-loop potential.

Manufacturers are continuously working to improve the environmental profile of LDPE film. Efforts include reducing the thickness of the film without compromising its strength to minimize material usage and exploring the addition of biodegradable additives to enhance the film's breakdown process after its useful life.

It's also worth noting that the lightweight nature of LDPE film can lead to lower transportation emissions, as more product can be moved with less packaging weight, contributing to a reduction in overall environmental impact.

Addressing environmental concerns often involves broader industry cooperation and consumer awareness. Manufacturers encourage consumers to actively participate in recycling programs and provide clear labeling to facilitate proper disposal and recycling of LDPE film.

The path towards sustainability is a shared responsibility, and while LDPE film does pose challenges, the material's recyclability and capacity for innovation present a positive outlook for its role in an environmentally conscious future.

How to Choose the Right LDPE Film for Your Packaging Needs

Selecting the appropriate LDPE film for packaging requires careful consideration of various factors. The decision-making process is critical to ensure that the film not only meets the functional requirements of the product but also aligns with the company's branding and sustainability goals.

- Determine the primary use of the packaging. Is it to protect food items, bundle industrial components, or to wrap consumer goods? The use case will dictate the required properties of the LDPE film, such as barrier qualities, strength, or clarity.

- Assess the required film thickness. Thicker films offer more protection for heavier items, but if flexibility or cost is a concern, a thinner film may be more appropriate. Consider the balance between protection and material usage.

- Consider the intended packaging process. Will the film be used on automatic packaging lines that require a specific film strength or sealability? The film should be compatible with the machinery and processes of the packaging facility.

- Take into account the visual and branding requirements. If product visibility is essential or if the packaging needs to be printed with high-quality graphics, opt for a film with high clarity and good printability.

- Examine the availability of custom options such as color, UV protection, and biodegradable additives. These can enhance the product's marketability and meet consumer demands for environmentally friendly packaging.

- Ensure that the LDPE film meets all regulatory standards for safety and environmental compliance, especially when packaging food, pharmaceuticals, or other sensitive products.

It's also advisable to work closely with suppliers who can provide detailed information about their LDPE films. Engaging with experts who offer services like 'Request a Sample' or 'Request a Quote' can be beneficial. Such experts can guide you to make an informed choice that aligns with your specific packaging requirements.

Making the right LDPE film choice is a nuanced process that should be approached methodically, ensuring that the final selection provides the ideal convergence of functionality, aesthetics, cost-efficiency, and environmental consideration.

Innovations and Future Trends in LDPE Film Packaging

Innovation in packaging is continuous, and the future of LDPE film packaging looks to balance performance with sustainability. With a focus on environmental consciousness, innovations aim to make LDPE film more eco-friendly while enhancing its functional attributes.

One of the significant areas of development is in the use of advanced materials. Manufacturers are exploring the incorporation of new polymers and additives to LDPE films, which can increase their strength, barrier properties, or make them easier to recycle. These material changes are designed to maintain the usability and durability of LDPE while minimizing environmental impact.

Technological advancements in the manufacturing process are also evolving. Innovations include improving energy efficiency during production and reducing waste. For example, better precision in extrusion and cutting processes leads to less material usage and a lower volume of offcuts.

The use of biodegradable and compostable additives represents a promising trend. These compounds are designed to break down more quickly in certain environments, helping to alleviate the issue of long-term plastic waste. However, these innovations are carefully balanced to ensure that the film still provides adequate protection during the product's shelf life.

Another exciting trend is the integration of smart technologies. There is ongoing research into embedding sensors or RFID tags within LDPE film, providing benefits like real-time tracking, freshness indicators for food packaging, or aiding in the recycling process.

Finally, industry collaboration and consumer engagement reflect significant future movements. Establishing clearer recycling streams and educating consumers on proper disposal are critical steps in improving the life cycle management of LDPE film packaging.

These innovations are indicative of an industry that is constantly redefining the possibilities of packaging. LDPE film is poised to adapt and thrive, offering practical solutions that respect environmental concerns and deliver on evolving consumer expectations.

Contacting Manufacturers for LDPE Film Samples and Quotes

When it comes to sourcing LDPE film for your packaging needs, establishing a line of communication with manufacturers is a crucial step. Having direct contact with suppliers can provide a wealth of information regarding product options, customization, and pricing. Here is a guide on how to reach out to manufacturers for sample requests and quotations:

- Identify potential suppliers: Research manufacturers like Primex Plastics and Bostik who offer a range of LDPE film options. Look for those with a strong reputation for quality and customer service.

- Request samples: Before making a bulk purchase, it's wise to see and test the film. Manufacturers typically offer a 'Request a Sample' service. Use this to evaluate the film's quality and suitability for your product.

- Gather your specifications: Have a clear idea of your requirements, including film thickness, color, and any special properties needed. This information will be critical for obtaining an accurate quote.

- Ask for a quote: Use the manufacturer's 'Request a Quote' service to get detailed pricing information. Provide your specifications and inquire about volume discounts or any other cost-saving options they might offer.

- Discuss customization options: If you require customized features for your LDPE film, discuss these with the manufacturer to understand how they can accommodate your needs and any associated costs.

- Consider sustainability: If environmental impact is a concern for your company, inquire about the manufacturer's sustainable practices and any eco-friendly LDPE film options they may have.

- Clarify lead times and logistics: Understanding how long it will take to receive your order and the logistics involved is vital for seamless integration into your production process.

Manufacturers like Brentwood Plastics Inc, located at 6035 Lindell Blvd, St. Louis, MO 63112, offer additional contact methods, ensuring personalized service. You can reach out to specific contacts such as Sam Longstreth via email or call at 800.466.1135 for custom price inquiries. Additional contact methods include calling 314 – 968 – 1135 for direct assistance.

By taking these steps and utilizing the tools and services offered by LDPE film manufacturers, you can ensure that the product you choose aligns with your business’s specific packaging needs and quality standards.

FAQ on LDPE Film Applications in Packaging

What are the key advantages of using LDPE film for packaging?

LDPE film offers flexibility, optical clarity, toughness, heat-sealability, and cost-efficiency, making it a versatile material for packaging that's able to adapt to various shapes and contents and provide a strong moisture barrier while being economically feasible.

How does LDPE film contribute to sustainability in packaging?

LDPE film is fully recyclable, which means it can be reprocessed into new material and reduce the demand for virgin resources. Its ability to be recycled aligns with growing consumer expectations and efforts to minimize the environmental impact of packaging materials.

In which industries are LDPE films commonly used?

LDPE films are prevalent in several industries, including healthcare for medical supplies, food and beverage for perishable goods, agriculture for product protection, and even in textile and apparel for garments, thanks to their adaptability, durability, and food safety properties.

Can LDPE film be custom-tailored for specific packaging needs?

Yes, LDPE film can be produced in a range of thicknesses from 3 mil to 30 mil and is available in colors like green, natural, black, and clear. Additionally, the film can undergo various finishing processes such as printing and heat sealing for customized packaging solutions.

What processing techniques enhance the use of LDPE film in packaging?

Key processing techniques include heat welding or sealing for secure closures, printing for branding and regulatory info, as well as coating and lamination to provide additional film properties like enhanced barrier quality or finishes. These methods are tailored to optimize the film for its intended applications.