Posts on the Topic Pharmaceutical

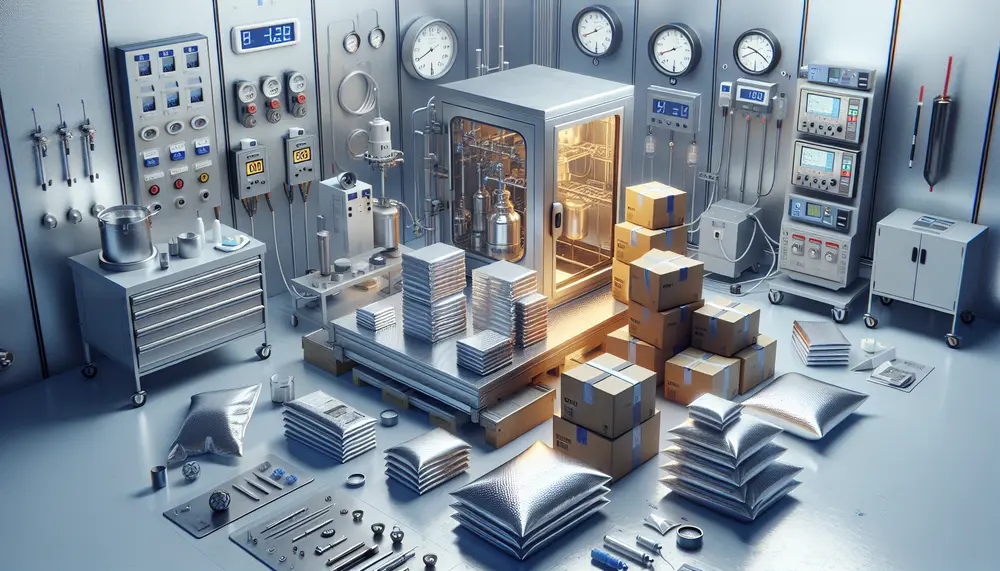

Pharmaceutical packaging is essential for product identification, protection, safe usage, marketing, and convenience while utilizing various materials like glass and plastics. Testing ensures that packaging meets safety standards and maintains the integrity of medications throughout their lifecycle....

The Comprehensive Guide to Pharmaceutical Packaging Testing Methods outlines essential testing techniques that ensure packaging integrity, safety, and compliance with regulatory standards. Key methods include accelerated aging tests, real-time aging tests, distribution simulation, cold chain testing, and shelf-life testing to...

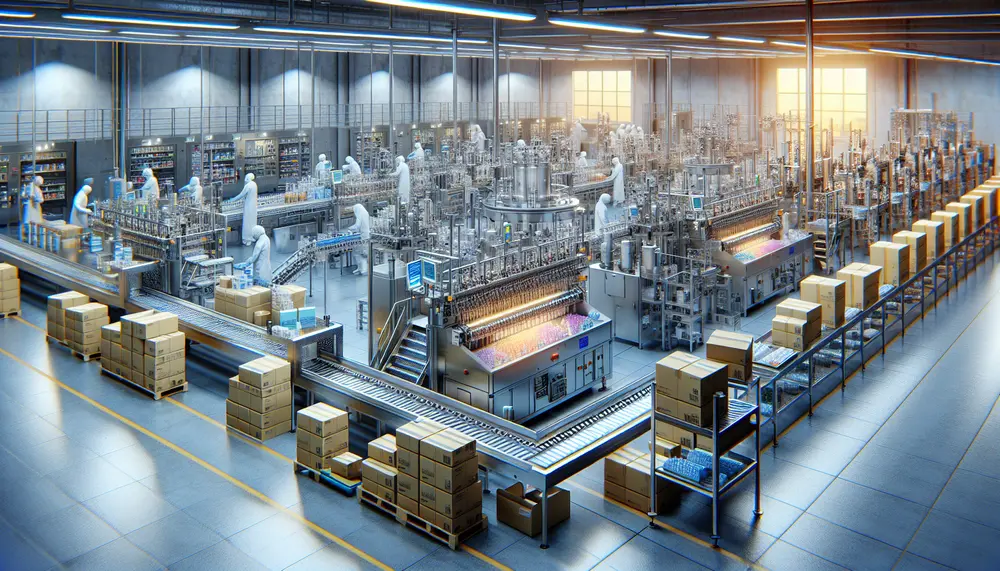

The pharmaceutical packaging equipment market in South Africa is rapidly evolving, driven by demand for high-quality solutions and regulatory compliance, featuring diverse machinery like Form-Fill-Seal and blister packaging machines. Key players such as SA Packaging Machinery and Uhlmann Pac-Systeme are...

Choosing the right pharmaceutical packaging trays is crucial for product integrity, regulatory compliance, and logistical efficiency, impacting overall quality and cost-effectiveness. Proper selection ensures protection against external factors while facilitating handling and storage in adherence to strict industry standards....

USP standards are essential in pharmaceutical packaging to ensure drug safety, efficacy, and regulatory compliance while preventing contamination. Plastic packaging systems play a crucial role by protecting medications through various applications like blister packs and vials, enhancing patient experience and...

Pharmaceutical container quality assurance now requires dynamic, risk-based systems with robust documentation and digitalization to meet evolving regulatory demands. Manufacturers must proactively manage risks, continuously improve processes, and ensure detailed audit trails to maintain compliance and product safety....

Visual storytelling on SlideShare revolutionizes pharmaceutical packaging communication by combining engaging visuals with concise content, simplifying complex concepts like material innovation, compliance, and design functionality. This approach fosters global collaboration, enhances understanding through interactive learning tools, and showcases key elements...

New Jersey is a leader in pharmaceutical packaging, offering innovative, sustainable solutions and leveraging its strategic location, skilled workforce, and advanced technologies. The state excels in services like cold-chain management, eco-friendly materials, serialization systems, and custom packaging while addressing challenges...

Pharmaceutical waste includes unused, expired medications that require proper disposal to prevent environmental contamination and health risks; safe disposal involves removing personal information, mixing with unpleasant substances, sealing in a durable container, and disposing of it responsibly....

Multiple choice questions (MCQs) are an efficient and versatile tool for testing knowledge in pharmaceutical packaging, covering topics like materials, manufacturing processes, and regulatory standards while offering immediate feedback but may oversimplify complex subjects. They help learners identify areas needing...

A Pharmaceutical Packaging Engineer is responsible for developing innovative packaging solutions that ensure medication safety and compliance with regulations, requiring a blend of technical expertise, creativity, and collaboration skills. The role offers significant growth opportunities in an environment focused on...

The pharmaceutical packaging validation protocol is crucial for ensuring product integrity and safety, involving material evaluation, process validation, equipment qualification (IQ, OQ, PQ), and adherence to international standards like ISO 11607. These steps help prevent recalls and ensure compliance with...

The pharmaceutical packaging industry is rapidly evolving with trends focusing on sustainability, smart technologies, and personalized solutions to meet consumer demands and regulatory requirements. While these innovations offer benefits like reduced environmental impact and enhanced patient engagement, they also present...

Pharmaceutical packaging is vital for ensuring medication safety and integrity, involving primary components that protect against environmental factors and secondary packaging that aids in branding and protection during transit. Technological advancements like automated inspection systems enhance quality control, while compliance...

Pharmaceutical food packaging combines principles from both pharmaceutical and food sectors to ensure product safety, efficacy, and compliance with stringent regulations. Key aspects include material selection, barrier properties, clear labeling, child-resistant features, traceability, quality control measures like GMP adherence, risk...

The pharmaceutical industry is evolving with innovations in packaging that enhance patient safety, improve drug efficacy, and meet regulatory requirements. Key advancements include smart blister packs for tracking medication adherence, high-barrier materials for protection against environmental factors, tamper-evident bottle features,...

The pharmaceutical packaging value chain is essential for ensuring medications are safely delivered from manufacturers to patients, involving steps like design and development, material selection, manufacturing processes, quality control, distribution logistics, regulatory compliance, and sustainability. Each component plays a crucial...

The pharmaceutical packaging HS code is essential for global trade, ensuring regulatory compliance, accurate tariff calculations, and efficient customs clearance. Understanding and correctly using the HS code helps businesses avoid delays, fines, and ensures smooth international operations by accurately classifying...

Starting a pharmaceutical packaging business involves understanding market demands, regulatory requirements, and sustainability trends. A comprehensive business plan covering executive summary, company description, market analysis, organizational structure, products/services offered, marketing strategy, financial projections, and risk mitigation is essential for securing...

The Pharmaceutical Packaging Exhibition showcased innovations in user-friendly and secure packaging, including smart technologies like NFC chips and QR codes for enhanced tracking and patient engagement. Key trends highlighted were sustainability with eco-friendly materials, digital integration using AR, advanced barrier...

Pharmaceutical packaging is essential for maintaining medication safety, stability, and compliance with regulatory standards; it protects from external elements and contamination while ensuring patient adherence through clear labeling and user-friendly designs. When choosing a pharmaceutical packaging manufacturer, consider their certifications,...

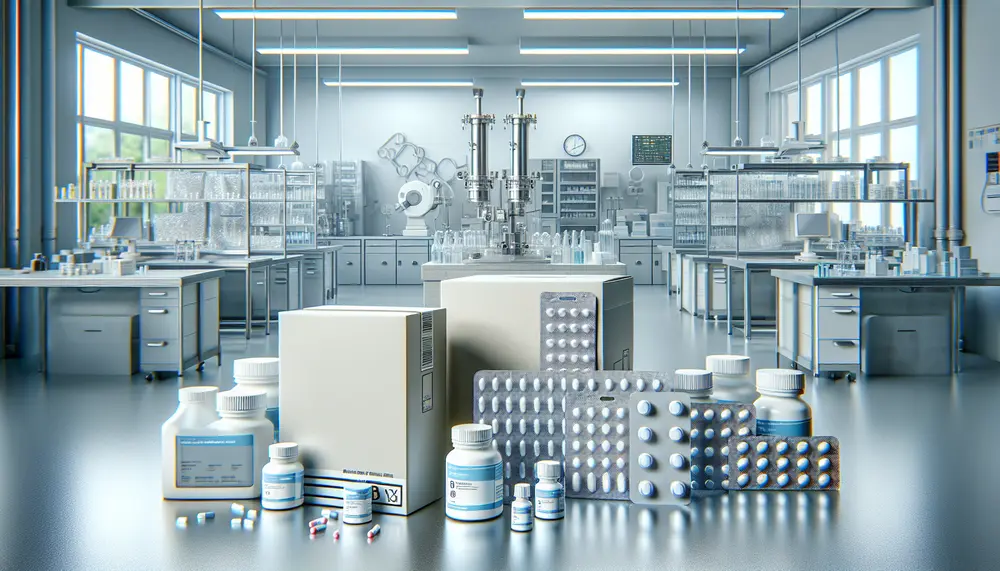

Pharmaceutical packaging is crucial for maintaining the safety, efficacy, and integrity of medications by protecting them from external factors like moisture and light, enhancing patient compliance with user-friendly designs such as dosing calendars, and extending product shelf life. Various types...

Pharmaceutical packaging is essential for maintaining the safety, efficacy, and quality of medications, involving various forms like blisters, bottles, and syringes to protect against damage, moisture, contamination, and tampering. The design of this packaging must consider material suitability, regulatory compliance...

Pharmaceutical packaging validation is a crucial process ensuring that each unit of pharmaceutical product meets regulatory standards and consumer safety through various assessments like design, installation, operational, and performance qualifications. This systematic approach includes ongoing verification to maintain compliance with...

Pharmaceutical packaging work involves designing, producing, and evaluating containers for medications to ensure safety and efficiency in delivery while maintaining product integrity through considerations like barrier protection and regulatory compliance. This field faces challenges such as material compatibility, regulatory adherence,...

Heat resistant packaging materials are designed to protect contents from high temperatures during transportation or storage, with various forms for different applications and levels of protection. Innovations aim to enhance heat resilience while considering cost-effectiveness and environmental impact. Thermal stability...

Pharmaceutical packaging is crucial for drug integrity and safety, balancing protection with patient convenience and regulatory compliance. Various materials like glass, plastics, aluminum foil, and biodegradable options are used to meet diverse needs in preserving quality while ensuring sustainability....