Posts on the Topic Integrity

The Comprehensive Guide to Pharmaceutical Packaging Testing Methods outlines essential testing techniques that ensure packaging integrity, safety, and compliance with regulatory standards. Key methods include accelerated aging tests, real-time aging tests, distribution simulation, cold chain testing, and shelf-life testing to...

Avis Industrial Corporation is a leader in the industrial parts supply sector, known for its innovative and customer-centric approach that emphasizes quality, sustainability, and tailored solutions. Guided by core values of integrity, respect, responsibility, and excellence, Avis fosters strong client...

Packaging damages can arise from various factors, including physical impacts, moisture and temperature fluctuations, contamination, structural flaws, and environmental influences. Understanding these types of damage is crucial for companies to implement effective strategies to minimize risks and ensure product integrity...

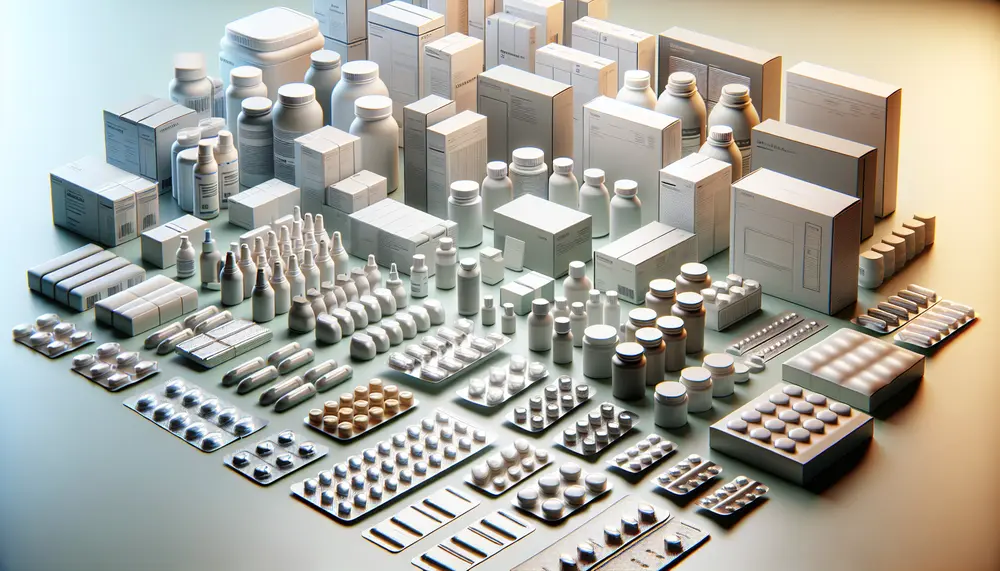

USP standards are essential in pharmaceutical packaging to ensure drug safety, efficacy, and regulatory compliance while preventing contamination. Plastic packaging systems play a crucial role by protecting medications through various applications like blister packs and vials, enhancing patient experience and...

Pharmaceutical packaging operators ensure product integrity and patient safety by managing complex machinery, maintaining strict documentation, troubleshooting issues, and collaborating with quality teams. The role demands adaptability, attention to detail, strong communication skills, compliance focus, and resilience in a fast-paced...

Pharma-grade packaging is a meticulously designed system that ensures the safety, stability, and usability of medications by protecting them from environmental factors, contamination, and degradation while meeting strict regulatory standards. It incorporates advanced materials, user-friendly features like tamper-evident seals, and...

Pharmaceutical packaging training is essential for ensuring medication safety and compliance with evolving regulations, empowering professionals to innovate and manage risks effectively while enhancing career opportunities. These dynamic programs combine theoretical knowledge with practical application through interactive sessions, self-paced modules,...

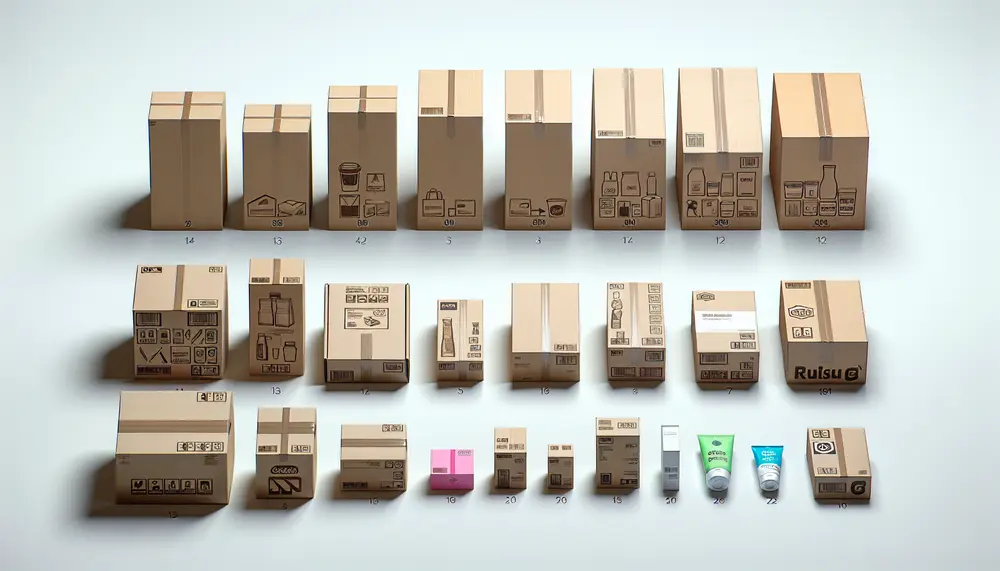

Protective packaging manufacturers design and produce solutions to safeguard products from damage, contamination, and environmental factors during transportation and storage. They work with various industries to create customized packaging using materials like foam, bubble wrap, corrugated cardboard, plastic films, barrier...

Protective packaging products are essential for safeguarding items during transit, storage, and handling by providing a buffer against damage from impacts, vibrations, moisture, and temperature fluctuations. This article explores various types of protective packaging such as bubble wrap, foam packaging,...

Protective packaging in the USA is essential for safeguarding products during storage and transportation, with companies offering advanced materials and custom solutions to protect against damage, moisture, and environmental factors. Key features include durability, moisture resistance, temperature control, customizability, ease...

Protective packaging is crucial for ensuring products reach customers in perfect condition, reducing damage and enhancing satisfaction. By choosing the right materials like bubble wrap, foam, or corrugated cardboard based on product characteristics and shipping conditions, businesses can optimize their...

Pharmaceutical food packaging combines principles from both pharmaceutical and food sectors to ensure product safety, efficacy, and compliance with stringent regulations. Key aspects include material selection, barrier properties, clear labeling, child-resistant features, traceability, quality control measures like GMP adherence, risk...

Glass is the preferred material for pharmaceutical packaging due to its chemical inertness, excellent barrier properties against gases and moisture, non-porous surface, recyclability, aesthetic appeal, temperature resistance, and light protection capabilities. These attributes ensure that medications remain pure, stable, effective...

Ensuring compliance in pharmaceutical packaging is essential for product integrity, patient safety, and regulatory approval. This article outlines key guidelines from major regulatory bodies like the FDA, EMA, ICH, WHO, and USP that govern material selection, design standards, labeling requirements,...

Pharmaceutical packaging is essential for maintaining medication safety, stability, and compliance with regulatory standards; it protects from external elements and contamination while ensuring patient adherence through clear labeling and user-friendly designs. When choosing a pharmaceutical packaging manufacturer, consider their certifications,...

Pharmaceutical packaging boxes are crucial for maintaining the safety, efficacy, and integrity of medications by protecting them from external factors like moisture and contamination, while also providing essential information to healthcare providers and patients. The selection process involves considering material...

Pharmaceutical packaging is crucial for maintaining the safety, efficacy, and integrity of medications by protecting them from external factors like moisture and light, enhancing patient compliance with user-friendly designs such as dosing calendars, and extending product shelf life. Various types...

Pharmaceutical packaging equipment is essential for maintaining the safety, integrity, and efficacy of medications by adhering to strict regulatory standards. This includes a variety of machines like blister pack machines, bottle filling machines, and labeling systems that ensure protective containment...

Pharmaceutical packaging validation is a crucial process ensuring that each unit of pharmaceutical product meets regulatory standards and consumer safety through various assessments like design, installation, operational, and performance qualifications. This systematic approach includes ongoing verification to maintain compliance with...

Pharmaceutical packaging is essential for protecting medications, ensuring safety and efficacy through materials like glass and plastics, and adhering to strict regulatory standards. Innovations in the field include biodegradable polymers and smart packaging technologies that enhance drug protection and environmental...

Pharmaceutical packaging is essential for maintaining the safety, integrity, and effectiveness of medications by protecting them from contamination, degradation, and tampering while ensuring they remain effective throughout their shelf life. It involves using various materials like glass, plastics, metals, and...

Product packaging is essential for protection, marketing, and providing consumer information; it influences brand perception and purchase decisions through design elements like color schemes. The design process involves research, feedback, prototyping, and technical considerations to ensure functionality and appeal. Choosing packaging...

Packaging hazards pose risks to product safety during transportation and storage, stemming from physical damage, environmental conditions, and human error; addressing these requires a comprehensive design strategy. Shipping hazards are categorized into shock damage, vibrations, compression forces, and atmospheric conditions;...

The UAE packaging industry is rapidly evolving, driven by economic growth and sustainability trends, with companies investing in R&D to meet the increasing demand for innovative and eco-friendly solutions. Digital transformation enhances supply chain efficiency through smart technologies as businesses...

Packaging in the USA market is essential for brand strategy, influencing consumer behavior and ensuring product protection. Trends like smart packaging, personalization, sustainability, and minimalist design are shaping the industry's future. Sustainable packaging enhances brand image but may incur higher costs...

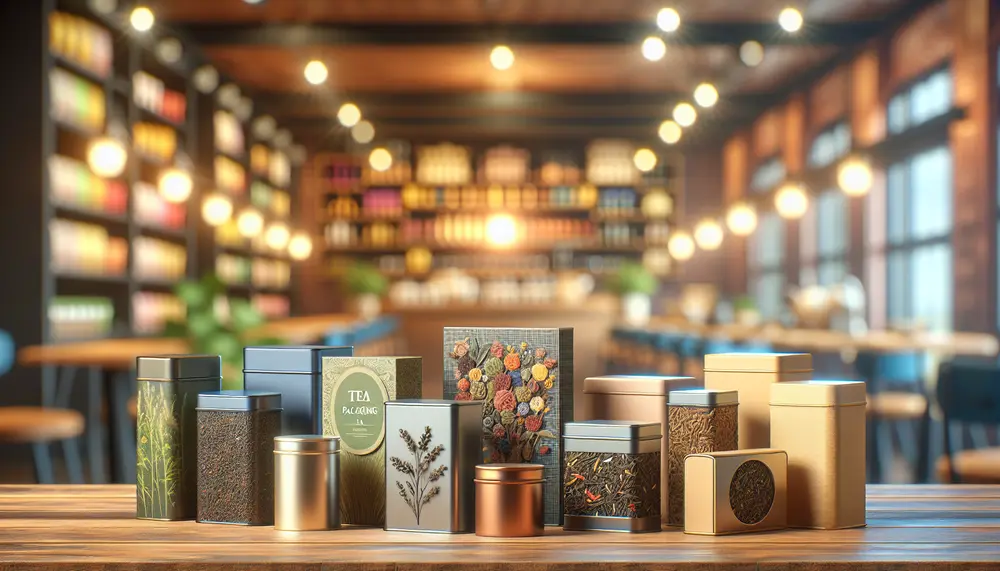

Tea packaging design is crucial for brand representation, customer engagement, and purchase decisions; it must also withstand shipping and reflect environmental responsibility through sustainable materials. Visual appeal in tea packaging influences consumer choice using color psychology, imagery, typography, tactile finishes,...