Posts on the Topic Material and Technology

Pharmaceutical packaging is essential for product identification, protection, safe usage, marketing, and convenience while utilizing various materials like glass and plastics. Testing ensures that packaging meets safety standards and maintains the integrity of medications throughout their lifecycle....

USP standards are essential in pharmaceutical packaging to ensure drug safety, efficacy, and regulatory compliance while preventing contamination. Plastic packaging systems play a crucial role by protecting medications through various applications like blister packs and vials, enhancing patient experience and...

Cost-effective packaging materials are crucial for businesses to optimize operations, enhance customer satisfaction, and reduce environmental impact while maintaining profitability. Innovative alternatives like paper packing materials and air pillows can replace traditional options like bubble wrap, offering both affordability and...

Packaging tissue paper is a versatile tool that enhances product protection and elevates brand presentation, offering various types and customizable options for unique business needs. Its color, design, and custom printing capabilities transform packaging into memorable customer experiences while reinforcing...

A well-structured Slideshare on packaging materials should use a clear narrative, visual comparisons, and actionable insights to guide viewers in choosing the right material. Each type—glass, metal, plastic, paper/board, composites, or biodegradable options—has unique strengths and weaknesses best matched to...

Selecting heavy duty packing kit components requires careful consideration of load capacity, material quality, compatibility, compliance, adaptability to contents, and supplier reputation. Choosing the right sizes and materials for boxes and protective packaging ensures maximum safety during shipping while specialized...

Quality protective packaging is essential for safeguarding sensitive goods, reducing waste and returns, maintaining product efficacy, and enhancing brand reputation. Protective Packaging Ltd ensures proven durability through advanced materials, rigorous testing, certified quality control, and global compliance—offering superior protection compared...

Heavy duty package scales ensure precise, consistent weighing for bulk shipments, reducing costly shipping errors and improving compliance with carrier requirements. Their use streamlines packaging processes, prevents overcharges or penalties, and boosts customer satisfaction by transforming guesswork into reliable accuracy....

Red alerts in pharmacy packaging are critical safety tools that use high-visibility design elements to prevent medication errors, benefiting both healthcare professionals and patients. By highlighting essential information like dosage limits or warnings against misuse, they enhance clarity, reduce risks...

Pharmaceutical glass vials are essential for ensuring drug safety, stability, and purity due to their chemical inertness, thermal resistance, and contamination prevention. Despite being fragile and costly compared to alternatives like plastics, they remain the gold standard in pharmaceutical packaging...

Packaging carton boxes are essential in modern industries for their versatility, protection, branding potential, and sustainability. With various types like folding cartons, rigid boxes, corrugated options, and insulated designs, they cater to diverse needs while balancing cost-efficiency and functionality....

Heavy duty plastic packaging bags are durable, versatile solutions designed to withstand heavy loads, harsh environments, and diverse industrial needs. Their waterproof, weather-resistant properties and customizable designs make them essential for protecting goods across sectors like agriculture, construction, food storage,...

Pharmaceutical packaging bottles are designed to protect, preserve, and deliver medications effectively while ensuring safety, regulatory compliance, and user convenience. Key considerations include material compatibility, barrier properties, child-resistant features, sterility assurance, sustainability efforts like bio-based plastics or glass alternatives for...

Heavy duty shrink packaging machines are transformative tools that enhance efficiency, reduce costs, and ensure product protection while boosting visual appeal and brand recognition. They provide durability, adaptability to demanding environments, optimized material usage, and advanced automation for industries aiming...

Protective packaging tubes are versatile, durable solutions designed to safeguard and transport items efficiently while offering features like transparency, adjustability, stackability, and chemical resistance. Made from materials such as PP, HDPE, and PVC for long-term use, these eco-friendly tubes cater...

Pharma-grade packaging is a meticulously designed system that ensures the safety, stability, and usability of medications by protecting them from environmental factors, contamination, and degradation while meeting strict regulatory standards. It incorporates advanced materials, user-friendly features like tamper-evident seals, and...

Multiple choice questions (MCQs) are an efficient and versatile tool for testing knowledge in pharmaceutical packaging, covering topics like materials, manufacturing processes, and regulatory standards while offering immediate feedback but may oversimplify complex subjects. They help learners identify areas needing...

Properly sealing moving boxes is crucial to protect belongings from damage and stress during a move, while heavy-duty packing tape offers strength, temperature resistance, versatility, and cost-effectiveness. Choosing the right tape involves considering width, adhesive quality, color for organization, environmental...

Heavy duty reinforced packing tape is a specialized, durable tape with fiberglass reinforcement and strong adhesion, ideal for securing heavy or bulky items during transit. Its advantages include enhanced strength, improved security, durability against environmental factors, cost-effectiveness, and versatility in...

Heavy duty packing foam, made from high-density polyethylene (PE) or polyurethane (PU), provides excellent cushioning and shock absorption for a wide range of items, ensuring damage-free deliveries. Its benefits include superior protection, versatility, durability, cost-effectiveness, lightweight nature, and ease of...

Pharmaceutical packaging innovations, such as temperature-sensitive labels and smart packaging with microprocessors, are enhancing drug safety, efficacy, and user convenience. These advancements help prevent contamination, ensure proper dosage management, and protect medications from environmental factors while improving patient adherence and...

Pharmaceutical packaging professionals ensure the safe and effective delivery of medical products by designing, testing, and managing packaging processes while adhering to regulatory standards. They face challenges such as regulatory compliance, counterfeit prevention, environmental concerns, cost management, technological advancements, and...

Pharmaceutical packaging and design are essential for ensuring medication safety, efficacy, and patient compliance. Effective packaging involves understanding regulatory requirements, material science, and user needs while providing protection, information, identification, convenience, and adherence to treatment plans; it must also comply...

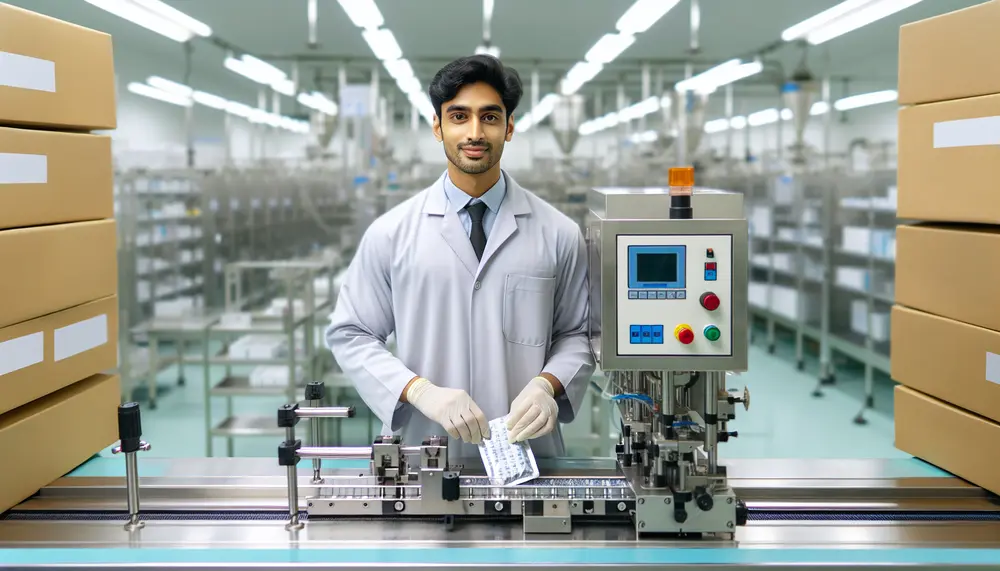

A pharmaceutical packaging technician ensures the safe and accurate packaging of medicines, maintaining product quality until it reaches consumers. This role requires technical proficiency, attention to detail, manual dexterity, problem-solving skills, and effective communication while adhering to industry standards like...

Ensuring compliance in pharmaceutical packaging is essential for product integrity, patient safety, and regulatory approval. This article outlines key guidelines from major regulatory bodies like the FDA, EMA, ICH, WHO, and USP that govern material selection, design standards, labeling requirements,...

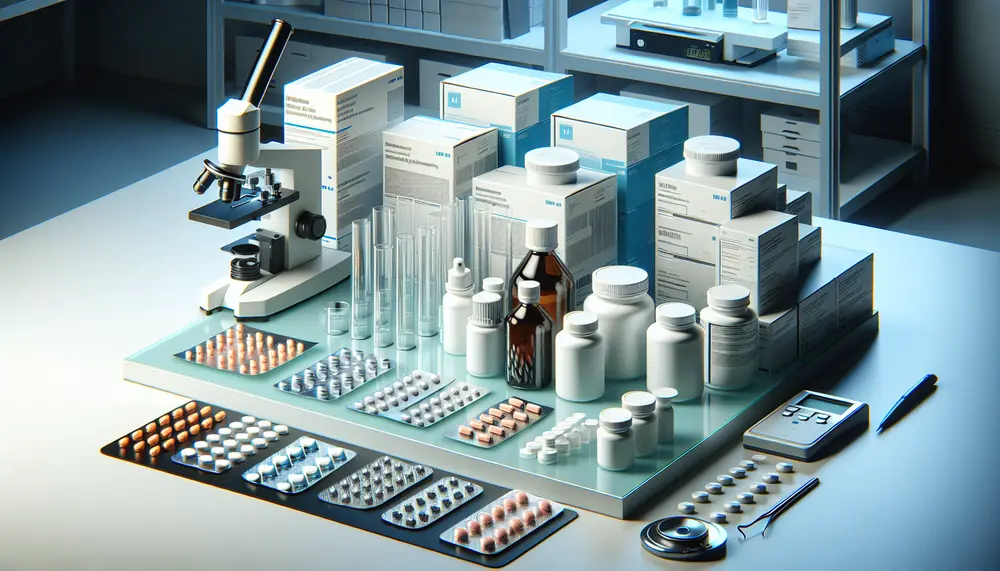

Understanding and selecting the right pharmaceutical packaging materials is essential for maintaining drug safety, efficacy, and integrity. These materials must protect against environmental factors like moisture and light while ensuring compatibility with the drugs they contain; innovations in this field...

The Pharmaceutical Packaging Exhibition showcased innovations in user-friendly and secure packaging, including smart technologies like NFC chips and QR codes for enhanced tracking and patient engagement. Key trends highlighted were sustainability with eco-friendly materials, digital integration using AR, advanced barrier...

Pharmaceutical packaging is essential for maintaining medication safety, stability, and compliance with regulatory standards; it protects from external elements and contamination while ensuring patient adherence through clear labeling and user-friendly designs. When choosing a pharmaceutical packaging manufacturer, consider their certifications,...

Pharmaceutical packaging boxes are crucial for maintaining the safety, efficacy, and integrity of medications by protecting them from external factors like moisture and contamination, while also providing essential information to healthcare providers and patients. The selection process involves considering material...

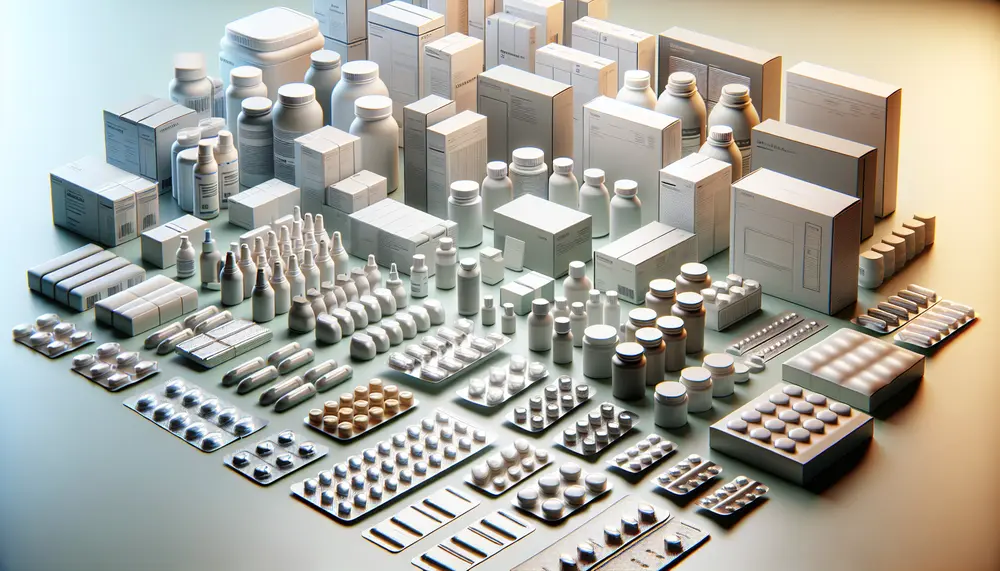

Pharmaceutical packaging is crucial for maintaining the safety, efficacy, and integrity of medications by protecting them from external factors like moisture and light, enhancing patient compliance with user-friendly designs such as dosing calendars, and extending product shelf life. Various types...

Pharmaceutical packaging is essential for maintaining the safety, efficacy, and quality of medications, involving various forms like blisters, bottles, and syringes to protect against damage, moisture, contamination, and tampering. The design of this packaging must consider material suitability, regulatory compliance...

Pharmaceutical packaging lines are essential in the pharmaceutical industry, ensuring drugs are safely and securely packaged to maintain their integrity and comply with stringent regulations. These systems incorporate advanced technologies like robotics, AI, and track-and-trace systems to enhance operational efficiency...

The pharmaceutical packaging industry in India is crucial for global healthcare, focusing on safe drug distribution and innovative solutions like tamper-evident features while adapting to market needs with sustainable practices. The sector is experiencing robust growth, driven by innovations, health...

Pharmaceutical packaging equipment is essential for maintaining the safety, integrity, and efficacy of medications by adhering to strict regulatory standards. This includes a variety of machines like blister pack machines, bottle filling machines, and labeling systems that ensure protective containment...

Pharmaceutical packaging waste significantly contributes to global environmental issues, with plastics being a major component that ends up in landfills and oceans, releasing toxins and increasing carbon emissions. Efforts to address this include exploring sustainable materials like bio-based plastics and...

Pharmaceutical packaging validation is a crucial process ensuring that each unit of pharmaceutical product meets regulatory standards and consumer safety through various assessments like design, installation, operational, and performance qualifications. This systematic approach includes ongoing verification to maintain compliance with...

A pharmaceutical packaging technician is essential in the healthcare industry, responsible for accurately packaging medications while adhering to strict regulations and maintaining safety standards. Their role involves operating machinery, manual tasks, quality control checks, and effective communication within teams to...

Pharmaceutical packaging is essential for protecting medications, ensuring safety and efficacy through materials like glass and plastics, and adhering to strict regulatory standards. Innovations in the field include biodegradable polymers and smart packaging technologies that enhance drug protection and environmental...

Pharmaceutical packaging work involves designing, producing, and evaluating containers for medications to ensure safety and efficiency in delivery while maintaining product integrity through considerations like barrier protection and regulatory compliance. This field faces challenges such as material compatibility, regulatory adherence,...

Pharmaceutical packaging is essential for maintaining the safety, integrity, and effectiveness of medications by protecting them from contamination, degradation, and tampering while ensuring they remain effective throughout their shelf life. It involves using various materials like glass, plastics, metals, and...

The pharmaceutical packaging industry is essential for protecting medications from contamination and degradation, involving a variety of materials and technologies to ensure product safety and regulatory compliance. Recent trends include the adoption of smart packaging with features like QR codes...

Packaging is critical for food safety and freshness, providing a barrier against contaminants and extending shelf life through innovations like modified atmosphere packaging. It also protects from physical damage during distribution, playing an essential role in preventing foodborne illness. Choosing the...

The Packaging Corporation of America (PCA) is a leader in innovative packaging solutions, enhancing brand recognition and sustainability with advanced designs and materials. PCA's custom-engineered options cater to diverse industries, integrating technology for efficiency and quality assurance while focusing on...

Traditional packaging materials, derived from nature and reflecting past ingenuity and environmental consciousness, symbolize a time of resourcefulness and minimal waste. These biodegradable materials offer sustainability benefits such as lower energy production processes, carbon sequestration, and support for biodiversity. A variety...

Packaging materials are crucial for product protection, branding, and environmental impact; choosing the right type depends on various factors including the product's nature and consumer trends. Paper-based options like corrugated cardboard and SBS paperboard offer sustainable choices with different balances...

Understanding the Basics of Packaging Materials in Agriculture: Agricultural packaging is essential for protecting produce during transport and extending shelf life, with material choice balancing product needs, efficiency, marketing appeal, and sustainability. Choosing the Right Packaging for Your Agricultural Products: Selecting...

Packaging film rolls are versatile plastic sheets used for securing and protecting products during transit and storage, with varying sizes and stretchability. They offer advantages like cost savings, protection from damage, adaptability to different product shapes, reduced environmental impact through...

The article discusses the significance of yogurt packaging materials in preserving quality, extending shelf life, and marketing. It highlights various types of packaging like glass, plastic, composites, eco-friendly alternatives, and metal containers with their respective properties. Packaging choices for yogurt impact...

Packaging materials range from traditional paper and glass to modern bioplastics, each with unique properties affecting product safety, cost-effectiveness, and environmental impact. Selecting the right packaging is crucial for brand identity, customer satisfaction, and sustainability; factors like protection needs, branding...

Packaging technicians play a crucial role in product delivery, operating machinery and selecting materials while prioritizing safety and quality. They require skills like basic math, GMP knowledge, analytical thinking, computer proficiency, teamwork, and communication to succeed. The job of a packaging...

Advanced packaging machines enhance efficiency and productivity in modern production lines by automating tasks, ensuring precision, and enabling cost savings. They are crucial for businesses to stay competitive and meet industry standards. High-efficiency packaging machines feature user-friendly interfaces, modular designs, precise...

Choosing the right cutlery set enhances both style and dining experience, with high-quality materials offering long-term value and comfort. Premium cutlery sets reflect personal taste, cultural significance, and can be eco-friendly; material quality is crucial for durability and aesthetics influence...

Monomaterial packaging, made from a single material for improved recyclability and production efficiency, faces challenges in maintaining product protection while research continues to develop suitable materials. The shift towards monomaterials aids the environment by reducing carbon footprints and waste, streamlining...

HDPE cutouts, made from High-Density Polyethylene, offer benefits like impact resistance and moisture repellence for packaging and products in various industries due to their strength and versatility. They are customizable, easy to maintain, environmentally friendly through recyclability, thermally stable with...

Food packaging is essential for protecting food, extending shelf life, and maintaining quality from production to consumption. It must meet safety standards, provide consumer information, facilitate transportation, enhance marketability, and support sustainability efforts. Innovative food packaging solutions address demands for convenience...

The European Union's packaging framework emphasizes environmental responsibility and sets quality and safety benchmarks for market-circulating packaging, requiring a life cycle approach from manufacturing to disposal/recycling. Businesses must understand these evolving standards to ensure compliance with the EU Packaging and...

Duplex paper is a two-layered packaging material known for its printability and structural integrity, widely used across industries due to its visual appeal and sturdiness. It's also eco-friendly, being recyclable and often made from sustainable sources. Advancements in duplex paper manufacturing...

RPET stands for recycled polyethylene terephthalate, a sustainable packaging material made from recycling used PET plastics. It reduces reliance on virgin plastic and conserves resources while maintaining quality through multiple life cycles. The journey of RPET bottles involves collection, sorting, cleaning,...

Packaging materials are essential for product protection, quality preservation, and shelf life extension across industries; they must balance protection with presentation and logistics efficiency. The food industry uses diverse packaging types like plastics, biodegradables, glass, metals, paper-based solutions to meet...

Pharmaceutical packaging is essential for product identification, protection, safe usage, marketing, and convenience while utilizing various materials like glass and plastics. Testing ensures that packaging meets safety standards and maintains the integrity of medications throughout their lifecycle....

Heavy duty packaging paper is strong, durable, and eco-friendly, making it ideal for secure shipping while enhancing brand image. Its versatility allows for various applications beyond traditional use, offering cost-effectiveness and sustainability benefits....

Choosing the right packing paper is essential for effective packaging, considering factors like item type, size, environmental impact, and cost. Heavy duty options offer enhanced protection and versatility for various applications such as moving, shipping, gift wrapping, and crafts....

Pack X-Ray technology uses X-rays to inspect packaging materials for quality and safety without opening them, enhancing efficiency across various industries like food and pharmaceuticals. Its ability to detect foreign objects and measure fill levels significantly improves product integrity while...

The Kertas packaging industry offers various platforms for inspiration, showcasing innovative designs and sustainable solutions. Current trends emphasize eco-friendly materials, minimalist aesthetics, personalization, interactivity, and vibrant visuals to enhance product appeal....

Heavy duty clear packing tape is a versatile and durable solution for various applications, from shipping and repairs to crafts and organization. Available in different price ranges on Amazon.com, it offers cost-effective options for both individuals and businesses while ensuring...

USP standards are essential in pharmaceutical packaging to ensure drug safety, efficacy, and regulatory compliance while preventing contamination. Plastic packaging systems play a crucial role by protecting medications through various applications like blister packs and vials, enhancing patient experience and...

Cost-effective packaging materials are crucial for businesses to optimize operations, enhance customer satisfaction, and reduce environmental impact while maintaining profitability. Innovative alternatives like paper packing materials and air pillows can replace traditional options like bubble wrap, offering both affordability and...

Packaging tissue paper is a versatile tool that enhances product protection and elevates brand presentation, offering various types and customizable options for unique business needs. Its color, design, and custom printing capabilities transform packaging into memorable customer experiences while reinforcing...

A well-structured Slideshare on packaging materials should use a clear narrative, visual comparisons, and actionable insights to guide viewers in choosing the right material. Each type—glass, metal, plastic, paper/board, composites, or biodegradable options—has unique strengths and weaknesses best matched to...

Selecting heavy duty packing kit components requires careful consideration of load capacity, material quality, compatibility, compliance, adaptability to contents, and supplier reputation. Choosing the right sizes and materials for boxes and protective packaging ensures maximum safety during shipping while specialized...

The Goat Protection Pack offers advanced, stylish sneaker protection with durable materials, ergonomic comfort, and innovative features for modern urban life. It sets new standards in footwear by combining resilience, weather resistance, and practical design without sacrificing style....

Quality protective packaging is essential for safeguarding sensitive goods, reducing waste and returns, maintaining product efficacy, and enhancing brand reputation. Protective Packaging Ltd ensures proven durability through advanced materials, rigorous testing, certified quality control, and global compliance—offering superior protection compared...

Heavy duty package scales ensure precise, consistent weighing for bulk shipments, reducing costly shipping errors and improving compliance with carrier requirements. Their use streamlines packaging processes, prevents overcharges or penalties, and boosts customer satisfaction by transforming guesswork into reliable accuracy....

Heavy duty food packaging trays use reinforced materials, advanced barriers, and smart design to keep food fresh, safe, and intact during storage or transport. Their material selection and innovative features ensure hygiene and durability for catering, takeout, schools, and more....

Red alerts in pharmacy packaging are critical safety tools that use high-visibility design elements to prevent medication errors, benefiting both healthcare professionals and patients. By highlighting essential information like dosage limits or warnings against misuse, they enhance clarity, reduce risks...

Pharmaceutical glass vials are essential for ensuring drug safety, stability, and purity due to their chemical inertness, thermal resistance, and contamination prevention. Despite being fragile and costly compared to alternatives like plastics, they remain the gold standard in pharmaceutical packaging...

Packaging carton boxes are essential in modern industries for their versatility, protection, branding potential, and sustainability. With various types like folding cartons, rigid boxes, corrugated options, and insulated designs, they cater to diverse needs while balancing cost-efficiency and functionality....

Heavy duty plastic packaging bags are durable, versatile solutions designed to withstand heavy loads, harsh environments, and diverse industrial needs. Their waterproof, weather-resistant properties and customizable designs make them essential for protecting goods across sectors like agriculture, construction, food storage,...

Jelly cases stand out for their blend of flexibility, durability, and style, crafted from materials like TPU or silicone that provide shock absorption and a snug fit. They offer lightweight protection with customizable designs but may attract dust or yellow...

Pharmaceutical packaging bottles are designed to protect, preserve, and deliver medications effectively while ensuring safety, regulatory compliance, and user convenience. Key considerations include material compatibility, barrier properties, child-resistant features, sterility assurance, sustainability efforts like bio-based plastics or glass alternatives for...

Heavy duty shrink packaging machines are transformative tools that enhance efficiency, reduce costs, and ensure product protection while boosting visual appeal and brand recognition. They provide durability, adaptability to demanding environments, optimized material usage, and advanced automation for industries aiming...

Protective packaging tubes are versatile, durable solutions designed to safeguard and transport items efficiently while offering features like transparency, adjustability, stackability, and chemical resistance. Made from materials such as PP, HDPE, and PVC for long-term use, these eco-friendly tubes cater...

Pharma-grade packaging is a meticulously designed system that ensures the safety, stability, and usability of medications by protecting them from environmental factors, contamination, and degradation while meeting strict regulatory standards. It incorporates advanced materials, user-friendly features like tamper-evident seals, and...

Multiple choice questions (MCQs) are an efficient and versatile tool for testing knowledge in pharmaceutical packaging, covering topics like materials, manufacturing processes, and regulatory standards while offering immediate feedback but may oversimplify complex subjects. They help learners identify areas needing...

Volvo's commitment to safety is reflected in their holistic approach, comprehensive protection packages, and societal goals like Vision 2020; they offer tailored maintenance plans that provide peace of mind by locking in service costs....

Void fill in packaging is crucial for protecting products during transit and enhancing the unboxing experience, with various materials like packing paper, bubble wrap, and air pillows offering different benefits and drawbacks....

Heavy duty packing tape dispensers are essential tools for efficient and secure packaging, offering features like sharp blades, tension control, and ergonomic designs to streamline the sealing process. They come in various types such as handheld, tabletop, and automatic models...

Pharmaceutical packaging in South Africa is a complex blend of science and art focused on ensuring safe delivery of medicines, governed by strict regulations like GMP and overseen by SAHPRA to maintain high safety standards....

Properly sealing moving boxes is crucial to protect belongings from damage and stress during a move, while heavy-duty packing tape offers strength, temperature resistance, versatility, and cost-effectiveness. Choosing the right tape involves considering width, adhesive quality, color for organization, environmental...

Bulk packaging is a crucial component of logistics, focusing on efficiency and cost-saving by using large containers like IBCs, drums, and pail buckets to transport substantial quantities of goods safely. It involves selecting the right materials—such as fiberboard boxes or...

Heavy duty reinforced packing tape is a specialized, durable tape with fiberglass reinforcement and strong adhesion, ideal for securing heavy or bulky items during transit. Its advantages include enhanced strength, improved security, durability against environmental factors, cost-effectiveness, and versatility in...

Heavy duty packing foam, made from high-density polyethylene (PE) or polyurethane (PU), provides excellent cushioning and shock absorption for a wide range of items, ensuring damage-free deliveries. Its benefits include superior protection, versatility, durability, cost-effectiveness, lightweight nature, and ease of...

Heavy duty packaging boxes are essential for protecting items during transit, offering enhanced durability through features like high burst strength, double or triple wall construction, moisture resistance, and reinforced corners. These boxes come in various types such as double wall,...

The heavy duty packaging cord in Black Desert Online (BDO) is essential for securely transporting goods, offering high tensile strength, durability, flexibility, weather resistance, and ease of use. Proper usage involves gathering items, positioning the cord evenly around them, tying...

Heavy duty packaging tape is a specialized adhesive tape designed for securing heavy or bulky items during shipping and storage, offering enhanced strength, durability, and resistance to harsh conditions compared to regular packaging tape. It features high adhesive strength, thick...

Pharmaceutical packaging innovations, such as temperature-sensitive labels and smart packaging with microprocessors, are enhancing drug safety, efficacy, and user convenience. These advancements help prevent contamination, ensure proper dosage management, and protect medications from environmental factors while improving patient adherence and...

Pharmaceutical packaging professionals ensure the safe and effective delivery of medical products by designing, testing, and managing packaging processes while adhering to regulatory standards. They face challenges such as regulatory compliance, counterfeit prevention, environmental concerns, cost management, technological advancements, and...

Pharmaceutical packaging and design are essential for ensuring medication safety, efficacy, and patient compliance. Effective packaging involves understanding regulatory requirements, material science, and user needs while providing protection, information, identification, convenience, and adherence to treatment plans; it must also comply...

A pharmaceutical packaging technician ensures the safe and accurate packaging of medicines, maintaining product quality until it reaches consumers. This role requires technical proficiency, attention to detail, manual dexterity, problem-solving skills, and effective communication while adhering to industry standards like...

Ensuring compliance in pharmaceutical packaging is essential for product integrity, patient safety, and regulatory approval. This article outlines key guidelines from major regulatory bodies like the FDA, EMA, ICH, WHO, and USP that govern material selection, design standards, labeling requirements,...

Understanding and selecting the right pharmaceutical packaging materials is essential for maintaining drug safety, efficacy, and integrity. These materials must protect against environmental factors like moisture and light while ensuring compatibility with the drugs they contain; innovations in this field...

The Pharmaceutical Packaging Exhibition showcased innovations in user-friendly and secure packaging, including smart technologies like NFC chips and QR codes for enhanced tracking and patient engagement. Key trends highlighted were sustainability with eco-friendly materials, digital integration using AR, advanced barrier...

Pharmaceutical packaging is essential for maintaining medication safety, stability, and compliance with regulatory standards; it protects from external elements and contamination while ensuring patient adherence through clear labeling and user-friendly designs. When choosing a pharmaceutical packaging manufacturer, consider their certifications,...

Pharmaceutical packaging boxes are crucial for maintaining the safety, efficacy, and integrity of medications by protecting them from external factors like moisture and contamination, while also providing essential information to healthcare providers and patients. The selection process involves considering material...

Pharmaceutical packaging is crucial for maintaining the safety, efficacy, and integrity of medications by protecting them from external factors like moisture and light, enhancing patient compliance with user-friendly designs such as dosing calendars, and extending product shelf life. Various types...

Pharmaceutical packaging is essential for maintaining the safety, efficacy, and quality of medications, involving various forms like blisters, bottles, and syringes to protect against damage, moisture, contamination, and tampering. The design of this packaging must consider material suitability, regulatory compliance...

The role of a pharmaceutical packaging operator is vital in ensuring the safety and efficacy of medications by handling the final stage of drug production, which includes operating specialized machinery to package various forms such as tablets and liquids while...

Pharmaceutical packaging lines are essential in the pharmaceutical industry, ensuring drugs are safely and securely packaged to maintain their integrity and comply with stringent regulations. These systems incorporate advanced technologies like robotics, AI, and track-and-trace systems to enhance operational efficiency...

The pharmaceutical packaging industry in India is crucial for global healthcare, focusing on safe drug distribution and innovative solutions like tamper-evident features while adapting to market needs with sustainable practices. The sector is experiencing robust growth, driven by innovations, health...

Pharmaceutical packaging equipment is essential for maintaining the safety, integrity, and efficacy of medications by adhering to strict regulatory standards. This includes a variety of machines like blister pack machines, bottle filling machines, and labeling systems that ensure protective containment...

Pharmaceutical packaging waste significantly contributes to global environmental issues, with plastics being a major component that ends up in landfills and oceans, releasing toxins and increasing carbon emissions. Efforts to address this include exploring sustainable materials like bio-based plastics and...

Pharmaceutical packaging validation is a crucial process ensuring that each unit of pharmaceutical product meets regulatory standards and consumer safety through various assessments like design, installation, operational, and performance qualifications. This systematic approach includes ongoing verification to maintain compliance with...

A pharmaceutical packaging technician is essential in the healthcare industry, responsible for accurately packaging medications while adhering to strict regulations and maintaining safety standards. Their role involves operating machinery, manual tasks, quality control checks, and effective communication within teams to...

Pharmaceutical packaging is essential for protecting medications, ensuring safety and efficacy through materials like glass and plastics, and adhering to strict regulatory standards. Innovations in the field include biodegradable polymers and smart packaging technologies that enhance drug protection and environmental...

Pharmaceutical packaging work involves designing, producing, and evaluating containers for medications to ensure safety and efficiency in delivery while maintaining product integrity through considerations like barrier protection and regulatory compliance. This field faces challenges such as material compatibility, regulatory adherence,...

Pharmaceutical packaging is essential for maintaining the safety, integrity, and effectiveness of medications by protecting them from contamination, degradation, and tampering while ensuring they remain effective throughout their shelf life. It involves using various materials like glass, plastics, metals, and...

The pharmaceutical packaging industry is essential for protecting medications from contamination and degradation, involving a variety of materials and technologies to ensure product safety and regulatory compliance. Recent trends include the adoption of smart packaging with features like QR codes...

Packaging is critical for food safety and freshness, providing a barrier against contaminants and extending shelf life through innovations like modified atmosphere packaging. It also protects from physical damage during distribution, playing an essential role in preventing foodborne illness. Choosing the...

The Packaging Corporation of America (PCA) is a leader in innovative packaging solutions, enhancing brand recognition and sustainability with advanced designs and materials. PCA's custom-engineered options cater to diverse industries, integrating technology for efficiency and quality assurance while focusing on...

EO sterilization is a vital low-temperature method for medical devices, requiring packaging that allows gas penetration and maintains sterility. Packaging materials like PE, PP, polystyrene, nylon, PET, and multilayer laminates are compatible with EO but must be designed to ensure...

Traditional packaging materials, derived from nature and reflecting past ingenuity and environmental consciousness, symbolize a time of resourcefulness and minimal waste. These biodegradable materials offer sustainability benefits such as lower energy production processes, carbon sequestration, and support for biodiversity. A variety...

Packaging materials are crucial for product protection, branding, and environmental impact; choosing the right type depends on various factors including the product's nature and consumer trends. Paper-based options like corrugated cardboard and SBS paperboard offer sustainable choices with different balances...

Packaging in dressmaking serves as both protection for garments and a marketing tool, enhancing brand image and customer experience. It includes various materials like plastic poly bags, paper products, cardboard boxes, fabric bags, bubble wrap/foam inserts; each chosen based on...

Understanding the Basics of Packaging Materials in Agriculture: Agricultural packaging is essential for protecting produce during transport and extending shelf life, with material choice balancing product needs, efficiency, marketing appeal, and sustainability. Choosing the Right Packaging for Your Agricultural Products: Selecting...

Packaging film rolls are versatile plastic sheets used for securing and protecting products during transit and storage, with varying sizes and stretchability. They offer advantages like cost savings, protection from damage, adaptability to different product shapes, reduced environmental impact through...

The article discusses the significance of yogurt packaging materials in preserving quality, extending shelf life, and marketing. It highlights various types of packaging like glass, plastic, composites, eco-friendly alternatives, and metal containers with their respective properties. Packaging choices for yogurt impact...

Packaging materials range from traditional paper and glass to modern bioplastics, each with unique properties affecting product safety, cost-effectiveness, and environmental impact. Selecting the right packaging is crucial for brand identity, customer satisfaction, and sustainability; factors like protection needs, branding...

Packaging technicians play a crucial role in product delivery, operating machinery and selecting materials while prioritizing safety and quality. They require skills like basic math, GMP knowledge, analytical thinking, computer proficiency, teamwork, and communication to succeed. The job of a packaging...

Advanced packaging machines enhance efficiency and productivity in modern production lines by automating tasks, ensuring precision, and enabling cost savings. They are crucial for businesses to stay competitive and meet industry standards. High-efficiency packaging machines feature user-friendly interfaces, modular designs, precise...

Plastic trays are essential in various industries for their customizable size, shape, and material, offering versatility from warehouse organization to sterilized medical packaging. They come in different designs like compartmentalized or vented ones and have evolved with eco-friendly options to...

Vacuum sealers extend food shelf life, prevent freezer burn, maintain quality and flavor, aid in portion control and meal planning, reduce waste, and save storage space. However, they come with initial costs for the machine and bags which can be...

Choosing the right cutlery set enhances both style and dining experience, with high-quality materials offering long-term value and comfort. Premium cutlery sets reflect personal taste, cultural significance, and can be eco-friendly; material quality is crucial for durability and aesthetics influence...

Monomaterial packaging, made from a single material for improved recyclability and production efficiency, faces challenges in maintaining product protection while research continues to develop suitable materials. The shift towards monomaterials aids the environment by reducing carbon footprints and waste, streamlining...

HDPE cutouts, made from High-Density Polyethylene, offer benefits like impact resistance and moisture repellence for packaging and products in various industries due to their strength and versatility. They are customizable, easy to maintain, environmentally friendly through recyclability, thermally stable with...

Food packaging is essential for protecting food, extending shelf life, and maintaining quality from production to consumption. It must meet safety standards, provide consumer information, facilitate transportation, enhance marketability, and support sustainability efforts. Innovative food packaging solutions address demands for convenience...

The European Union's packaging framework emphasizes environmental responsibility and sets quality and safety benchmarks for market-circulating packaging, requiring a life cycle approach from manufacturing to disposal/recycling. Businesses must understand these evolving standards to ensure compliance with the EU Packaging and...

Duplex paper is a two-layered packaging material known for its printability and structural integrity, widely used across industries due to its visual appeal and sturdiness. It's also eco-friendly, being recyclable and often made from sustainable sources. Advancements in duplex paper manufacturing...

RPET stands for recycled polyethylene terephthalate, a sustainable packaging material made from recycling used PET plastics. It reduces reliance on virgin plastic and conserves resources while maintaining quality through multiple life cycles. The journey of RPET bottles involves collection, sorting, cleaning,...

Packaging materials are essential for product protection, quality preservation, and shelf life extension across industries; they must balance protection with presentation and logistics efficiency. The food industry uses diverse packaging types like plastics, biodegradables, glass, metals, paper-based solutions to meet...

Top 10 posts in the category

Unsere Beiträge zum Thema Material and Technology

Explore the cutting-edge intersection of Material and Technology in the packaging industry. Our comprehensive collection of articles delivers an in-depth look into the innovations and advancements shaping the future of packaging materials and processes. By diving into our expert content, you'll gain a wealth of knowledge that can help you make informed decisions, reduce costs, and improve sustainability in your packaging solutions.

Unlock the potential of new Material and Technology developments with insights on the latest trends, from biodegradable materials to smart packaging technologies. Stay ahead of the curve with exclusive updates on research breakthroughs and application case studies that demonstrate the practical benefits of these innovations in real-world scenarios.

Enhance your competitive edge by understanding how Material and Technology contribute to product safety, brand perception, and customer experience. Our articles not only delve into the technical aspects but also examine the impact on consumer engagement and the role these elements play in creating packaging that stands out on the shelves.

Whether you're looking to optimize the functionality of your packaging or explore environmentally friendly options, our 'Material and Technology' category offers the insights you need. Let our expertly curated content guide your strategy and inspire your next packaging project, ensuring you are equipped with the knowledge to leverage the most innovative materials and technologies in the field.