Thermoplastic

Thermoplastic

Thermoplastic in Packaging

Thermoplastic is a type of plastic that becomes soft when heated and hard when cooled. This property makes it ideal for packaging. You can mold it into various shapes and sizes.

How Thermoplastic Works

When you heat thermoplastic, it melts. This allows you to shape it. Once it cools, it hardens again. This process is reversible, so you can reheat and reshape it multiple times.

Common Uses in Packaging

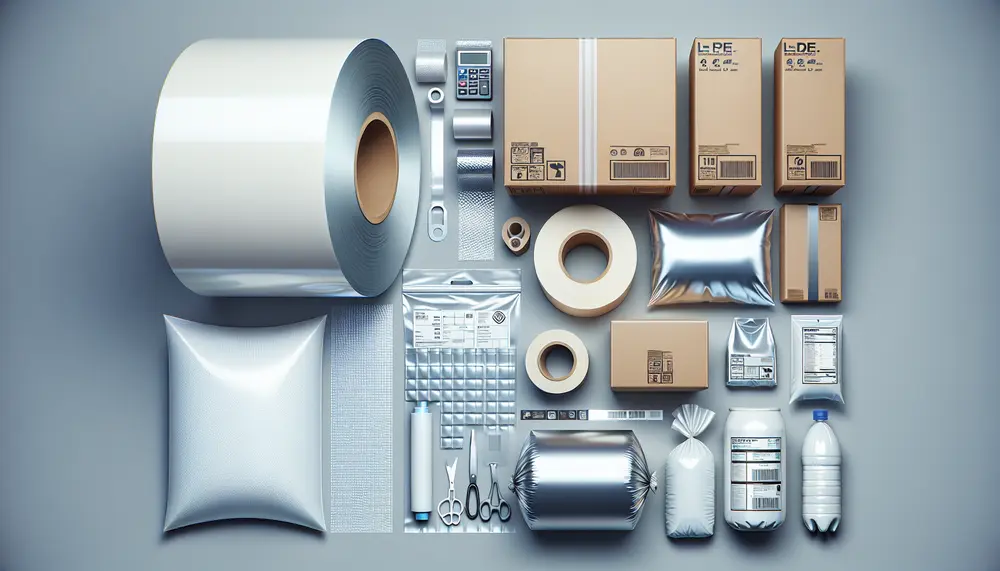

Thermoplastic is used in many packaging applications. For example, it is used to make bottles, containers, and films. Its flexibility and durability make it a popular choice.

Types of Thermoplastic

There are several types of thermoplastic. Some common ones include polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC). Each type has unique properties that suit different packaging needs.

Benefits of Using Thermoplastic

Thermoplastic offers many benefits for packaging. It is lightweight, which reduces shipping costs. It is also recyclable, making it an eco-friendly option. Additionally, it provides a strong barrier against moisture and contaminants.

Conclusion

In summary, thermoplastic is a versatile and practical material for packaging. Its ability to be reshaped and reused makes it a valuable resource in the packaging industry.

Blog Posts with the term: Thermoplastic

LDPE bags are versatile and durable packaging solutions made from Low-Density Polyethylene, suitable for a wide range of applications including food packaging, medical supplies, retail merchandise, industrial parts, and agricultural products. They offer benefits such as cost efficiency, protective qualities...

HDPE packaging is valued for its durability, lightweight nature, and resistance to environmental factors. It's versatile in shape and size customization, cost-effective during transport due to its light weight, and environmentally friendly as it's 100% recyclable. High-density polyethylene (HDPE) is a...

High-Density Polyethylene (HDPE) is a durable, versatile thermoplastic with a high strength-to-density ratio used in packaging, construction, and various other applications due to its resistance to impact and chemicals. HDPE's production involves polymerization of ethylene gas using different methods that...

HDPE bags are known for their strength, flexibility, and eco-friendliness due to their robust molecular structure; they resist impacts, chemicals, moisture, and temperature variations while being recyclable. Their durability allows multiple uses and secure transportation of goods with less environmental...

Packaging materials are crucial for product protection, branding, and environmental impact; choosing the right type depends on various factors including the product's nature and consumer trends. Paper-based options like corrugated cardboard and SBS paperboard offer sustainable choices with different balances...

Packaging materials are essential for product protection, information dissemination, and marketing; material selection is based on factors like durability and sustainability. Plastic packaging offers versatility but faces environmental concerns, glass provides purity and recyclability, metal ensures strength and long-term preservation...

LDPE film is a flexible, transparent thermoplastic used extensively in packaging for its chemical resistance and moisture barrier properties, which are crucial across industries like food, pharmaceuticals, and agriculture. It stands out due to its recyclability and balance of protection,...

Jelly cases stand out for their blend of flexibility, durability, and style, crafted from materials like TPU or silicone that provide shock absorption and a snug fit. They offer lightweight protection with customizable designs but may attract dust or yellow...

Composite materials are transforming the packaging industry by providing improved performance and durability, with their unique composition allowing for tailored properties to meet specific needs. Innovations in technology like smart composites, nanocomposites, and 3D printing are further advancing these materials'...

Plastic packaging for cleaning agents is designed to be chemically resistant and secure, with specific plastics chosen based on their interaction with the product's chemicals. Child-safe features like CR closures are essential for preventing accidental access by children. Eco-friendly plastic options...

The guide discusses the importance of choosing the right ice cream spoon, detailing various types based on material, design, ergonomics, and functionality. It also weighs pros and cons of different aspects like material durability versus environmental impact and ergonomic comfort...

PP lids for coffee cups are essential for preserving the aroma and heat of the beverage, offering a combination of strength, flexibility, and tight sealing. They are also recyclable and comply with regulations against certain plastics. Polypropylene (PP) is valued in...

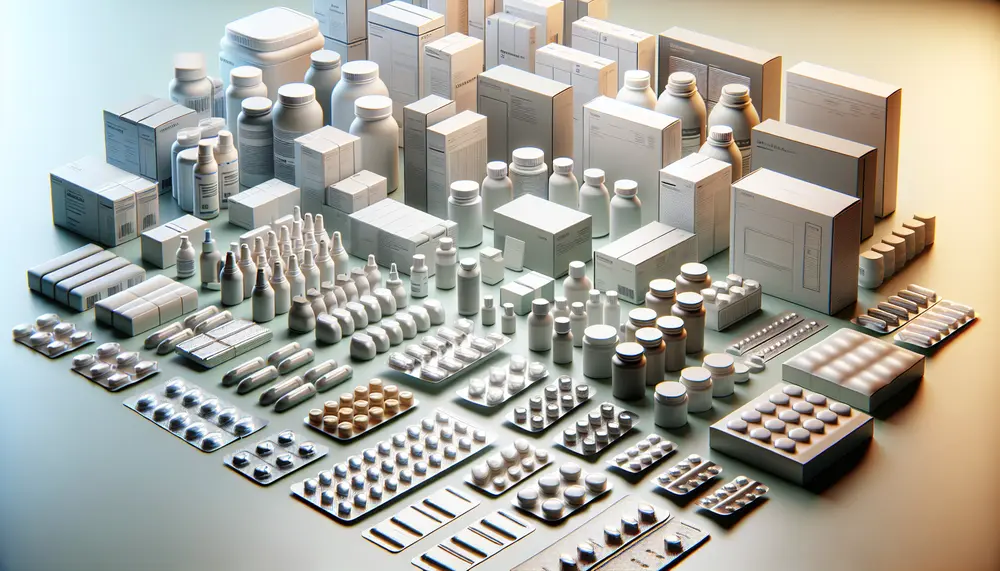

Pharmaceutical packaging is essential for protecting medications, ensuring safety and efficacy through materials like glass and plastics, and adhering to strict regulatory standards. Innovations in the field include biodegradable polymers and smart packaging technologies that enhance drug protection and environmental...

HDPE cutouts, made from High-Density Polyethylene, offer benefits like impact resistance and moisture repellence for packaging and products in various industries due to their strength and versatility. They are customizable, easy to maintain, environmentally friendly through recyclability, thermally stable with...