Tamper-proof

Tamper-proof

What is Tamper-proof Packaging?

**Tamper-proof** packaging is designed to protect products from unauthorized access or tampering. This type of packaging ensures that the product remains safe and intact until it reaches the consumer.

Why is Tamper-proof Packaging Important?

**Tamper-proof** packaging is crucial for maintaining product integrity and consumer trust. It prevents contamination, theft, and counterfeiting. For example, medicines and food items often use **tamper-proof** seals to ensure safety.

Common Types of Tamper-proof Packaging

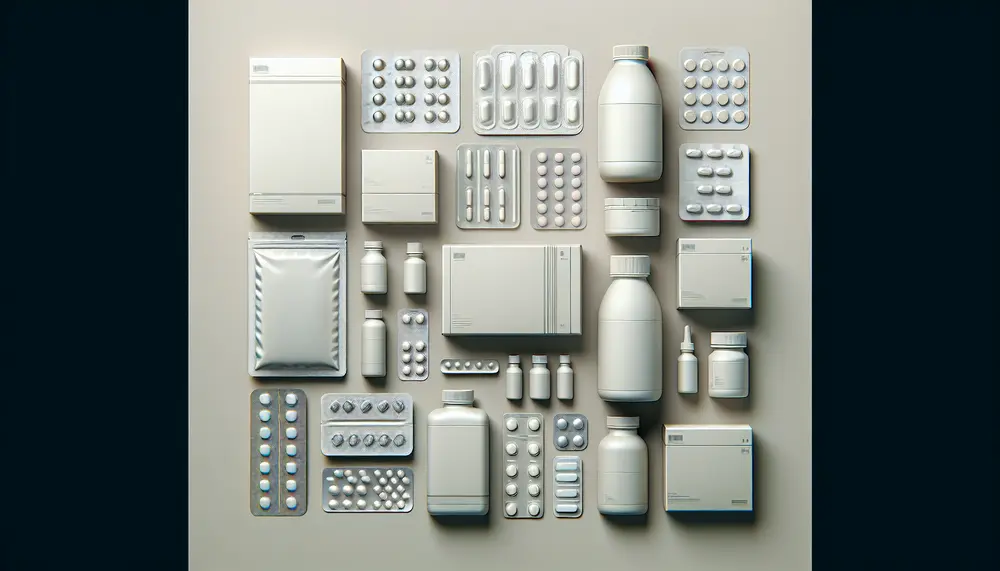

There are several types of **tamper-proof** packaging, including:

- **Seals and Bands**: These are placed around bottle caps or lids to show if the product has been opened.

- **Blister Packs**: Common in pharmaceuticals, these packs make it clear if a pill has been removed.

- **Shrink Wrap**: This film covers the entire product and must be removed before use, indicating tampering if broken.

Benefits of Tamper-proof Packaging

**Tamper-proof** packaging offers several benefits:

- **Safety**: Ensures the product is safe for consumption or use.

- **Trust**: Builds consumer confidence in the brand.

- **Compliance**: Meets regulatory requirements for certain products.

Examples of Tamper-proof Packaging in Everyday Life

You encounter **tamper-proof** packaging daily. Medicine bottles with seals, food jars with pop-up buttons, and electronic gadgets with security stickers are all examples. These measures help ensure that what you buy is safe and untouched.

Blog Posts with the term: Tamper-proof

OPP bags, known for their strength and clarity, are essential in packaging for protection, presentation, and preservation of products. They offer advantages like durability, resealability, cost-effectiveness but have drawbacks such as being non-biodegradable; various types exist to suit different applications. Different...

Tablet packaging materials are essential for protecting medication from contamination and damage, with properties tailored to the pharmaceutical product's needs. Secure tablet packaging is vital in maintaining drug potency, ensuring patient safety through tamper evidence, preventing misuse or accidental ingestion,...

Effective packaging design balances creativity and functionality, enhanced by modern technologies like CAD for precision; sustainability practices focus on eco-friendly materials, while efficient logistics streamline production to meet industry-specific needs, ultimately boosting brand reputation and customer satisfaction....

A packaging hub is a crucial node in distribution networks, centralizing the collection, sorting, and repackaging of products to optimize freight movements and reduce errors. These hubs offer additional services like inventory management and kitting while providing benefits such as...

Sustainable pharmaceutical packaging is under urgent scrutiny due to high CO₂ emissions, regulatory pressure, and the need for safe, recyclable solutions. Cutting-edge recycling technologies—like advanced mechanical sorting, chemical depolymerization, carbon capture polymers, bio-based materials, and digital watermarking—are driving a shift...

The pharmaceutical packaging market is rapidly growing due to regulatory demands, advanced therapies, and patient-centric innovations, with new materials like high-barrier polymers and smart technologies enhancing drug safety but increasing costs and complexity....

Packaging carton boxes are essential in modern industries for their versatility, protection, branding potential, and sustainability. With various types like folding cartons, rigid boxes, corrugated options, and insulated designs, they cater to diverse needs while balancing cost-efficiency and functionality....

Radioactive material packaging ensures safety during transport by containing radiation and preventing contamination. It involves understanding radioactivity levels, using shielding materials like lead or concrete, ensuring containment with robust seals, and adhering to strict regulations for different package types designed...

Pharma-grade packaging is a meticulously designed system that ensures the safety, stability, and usability of medications by protecting them from environmental factors, contamination, and degradation while meeting strict regulatory standards. It incorporates advanced materials, user-friendly features like tamper-evident seals, and...

The role of a pharmaceutical packaging operator is vital in ensuring the safety and efficacy of medications by handling the final stage of drug production, which includes operating specialized machinery to package various forms such as tablets and liquids while...

Pharmaceutical packaging in the EU plays a vital role beyond protection, ensuring safety, compliance, and sustainability while adapting to diverse market needs under strict regulations. Key frameworks like the Falsified Medicines Directive and European Green Deal drive innovation in traceability,...

Food grade production facilities must adhere to strict regulations like those from the FDA and implement systems such as HACCP to manage food safety risks, focusing on using non-toxic materials, maintaining cleanliness, and preventing contamination. These facilities also emphasize rigorous...

Industrial food packaging machines are essential for the efficient, safe, and consistent packaging of products in the food industry, enhancing product longevity and meeting mass production demands with technologies that extend shelf life and ensure regulatory compliance. Advancements in this...

Partnering with reliable packaging providers enhances efficiency, sustainability, and branding through tailored solutions like lightweight materials and optimized designs. These partnerships support eco-friendly practices, cost savings, scalability, and industry-specific needs while fostering long-term growth and environmental responsibility....

Heavy duty shrink packaging machines are transformative tools that enhance efficiency, reduce costs, and ensure product protection while boosting visual appeal and brand recognition. They provide durability, adaptability to demanding environments, optimized material usage, and advanced automation for industries aiming...