Machine

Machine

Machine in Packaging

A machine in the context of packaging refers to any equipment used to automate the process of packing products. These machines can handle various tasks such as filling, sealing, labeling, and wrapping. They are essential for improving efficiency and consistency in packaging operations.

Types of Packaging Machines

There are several types of packaging machines, each designed for specific tasks. Some common types include:

- Filling Machines: These machines are used to fill containers with products, such as liquids, powders, or granules.

- Sealing Machines: These machines seal packages to keep the contents secure and fresh.

- Labeling Machines: These machines apply labels to packages, providing important information like product details and barcodes.

- Wrapping Machines: These machines wrap products in materials like plastic or paper for protection and presentation.

Benefits of Using Machines in Packaging

Using machines in packaging offers several benefits:

- Efficiency: Machines can perform tasks faster than humans, increasing production speed.

- Consistency: Machines ensure that each package is identical, improving product quality.

- Cost Savings: Automating packaging processes can reduce labor costs and minimize waste.

Choosing the Right Machine

Selecting the right machine for your packaging needs depends on several factors:

- Product Type: Different products require different types of machines. For example, liquids need filling machines, while boxes may need sealing machines.

- Production Volume: High-volume production lines benefit from more advanced and faster machines.

- Budget: Consider the cost of the machine and the potential return on investment.

In conclusion, a machine in packaging is a crucial component for any business looking to improve its packaging process. By understanding the different types of machines and their benefits, you can make informed decisions to enhance your packaging operations.

Blog Posts with the term: Machine

Leaf-based packaging materials are ancient practices re-emerging for modern sustainability, utilizing plant leaves as biodegradable and renewable solutions with minimal environmental impact. They reduce carbon emissions compared to plastic production, decompose rapidly without toxic residues, and align with circular economy...

Cornstarch is a biodegradable, eco-friendly alternative to traditional packaging materials, offering similar functionalities with less environmental impact. It's used in various industries for products like containers and bags, reduces reliance on fossil fuels, and supports climate change efforts by emitting...

The Kenyan packaging market is valued at around $585 million, driven by sectors like agriculture and manufacturing which contribute to the GDP; growth in consumer demand has led to innovations such as small affordable packages and a shift towards sustainable...

The article discusses the significance of yogurt packaging materials in preserving quality, extending shelf life, and marketing. It highlights various types of packaging like glass, plastic, composites, eco-friendly alternatives, and metal containers with their respective properties. Packaging choices for yogurt impact...

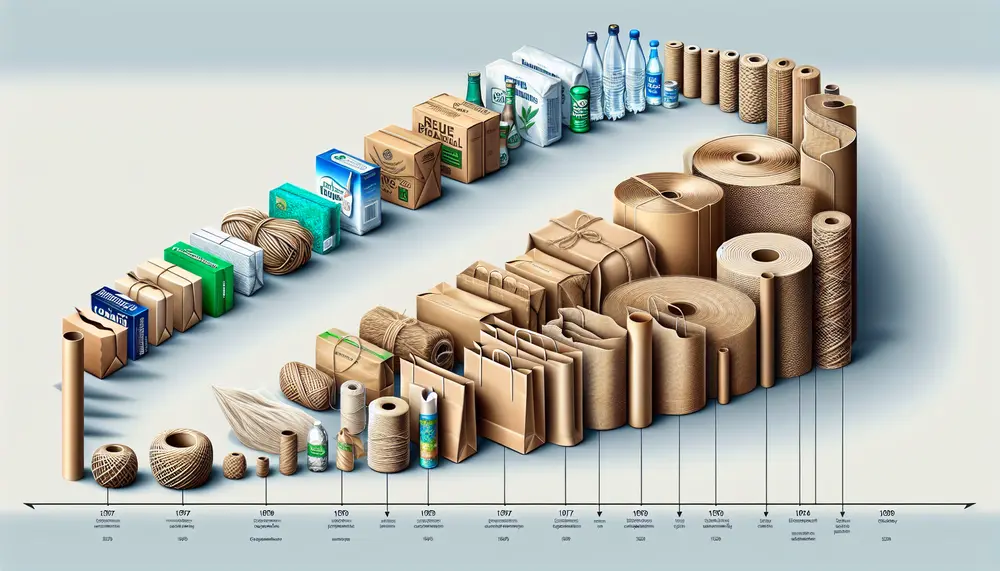

Packaging is a complex, engineered process for product protection, presentation, and preservation with functions including containment and information. It has evolved to incorporate user experience, environmental considerations, and technological advancements. Historically packaging materials have advanced from natural resources to modern lightweight...

A packaging operator oversees the final stages of manufacturing, ensuring products are correctly packed and labeled for shipping. Their responsibilities include managing machinery, preparing materials, monitoring operations, performing maintenance tasks, keeping production records and adhering to safety protocols while maintaining...

Glass packaging is valued for its durability, inertness, and transparency, ideal for storing various products while being 100% recyclable. Different types of glass like borosilicate and soda-lime are used in packaging due to their unique properties such as thermal resistance...

Understanding sustainable packaging is vital for businesses to minimize environmental impact and meet consumer demands, focusing on eco-friendly materials and practices. Key concepts include life cycle assessment, recyclability, and the circular economy, which guide companies in selecting suitable materials while...

Ensuring compliance in pharmaceutical packaging is essential for product integrity, patient safety, and regulatory approval. This article outlines key guidelines from major regulatory bodies like the FDA, EMA, ICH, WHO, and USP that govern material selection, design standards, labeling requirements,...

The packaging industry's value chain encompasses material procurement, design and development, manufacturing, distribution, marketing, sales, and after-sales service. Challenges such as environmental regulations, consumer demands for sustainability, cost volatility, technological advances, globalization issues, and supply chain complexity necessitate strategic planning...

The guide explains the significance of MOSH (Mineral Oil Saturated Hydrocarbons) and MOAH (Mineral Oil Aromatic Hydrocarbons) in food packaging, highlighting their potential health risks due to migration into food. It emphasizes the need for ongoing research, industry regulation, and...

The Critical Packing Parameter (CPP) is a crucial metric in surfactant science that predicts how molecules arrange themselves based on tail volume, head area, and tail length, aiding applications from detergents to drug delivery. Understanding CPP helps forecast molecular behavior...

The packaging and technology revolution is transforming product protection, preservation, and presentation through intelligent systems, AR/VR experiences, digital printing for customization, with a focus on data security in smart packaging solutions. This intersection of fields offers innovation opportunities across industries. Technology's...

The conical shape is a versatile design element with applications ranging from structural strength to aesthetic appeal, and its dimensions are critical for accurate execution. Its evolution in modern aesthetics spans various disciplines, symbolizing progress and innovation while offering practical...

Duplex paper is a two-layered packaging material known for its printability and structural integrity, widely used across industries due to its visual appeal and sturdiness. It's also eco-friendly, being recyclable and often made from sustainable sources. Advancements in duplex paper manufacturing...