Drum

Drum

Drum in Packaging

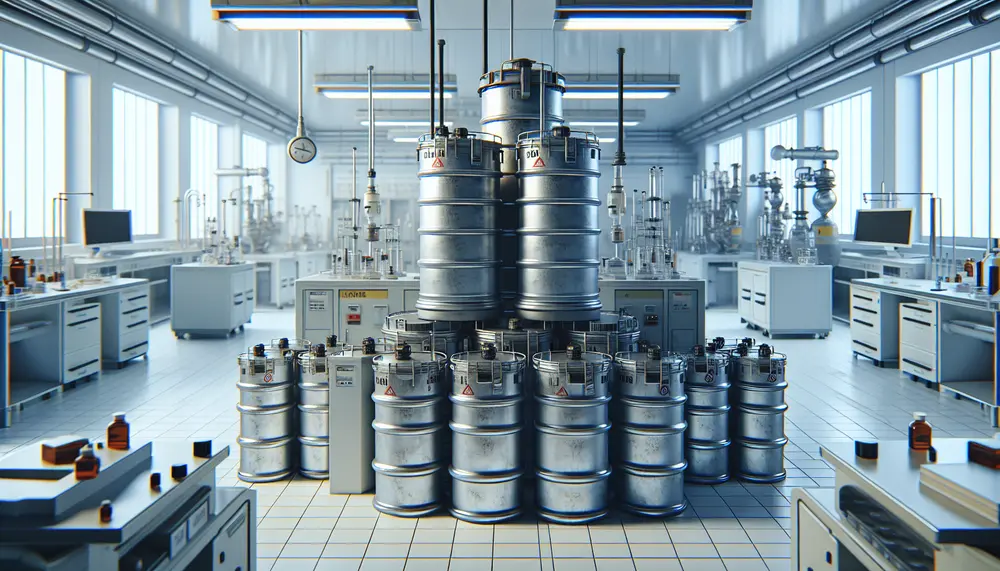

A drum is a cylindrical container used for storing and transporting various materials. Drums are commonly made from metal, plastic, or fiber. They are used in many industries, including chemicals, pharmaceuticals, and food.

Types of Drums

There are several types of drums, each suited for different purposes:

- Steel Drums: Ideal for hazardous materials due to their durability.

- Plastic Drums: Lightweight and resistant to corrosion, perfect for liquids.

- Fiber Drums: Made from dense paperboard, used for dry goods.

Advantages of Using Drums

Drums offer several benefits in packaging:

- Durability: Drums are strong and can withstand rough handling.

- Versatility: Suitable for a wide range of materials, from liquids to solids.

- Reusability: Many drums can be cleaned and reused, making them eco-friendly.

Common Uses of Drums

Drums are used in various applications:

- Chemical Storage: Safely store and transport chemicals.

- Food Ingredients: Store bulk food items like grains and syrups.

- Pharmaceuticals: Transport raw materials and finished products.

Conclusion

In the packaging world, a drum is a versatile and durable container. Whether made from steel, plastic, or fiber, drums are essential for safely storing and transporting a wide range of materials.

Blog Posts with the term: Drum

The packaging HS code is a ten-digit number essential for international trade, determining tariffs and ensuring compliance with regulations. It's part of the Harmonized System used globally by customs to classify products, where the first six digits are universal and...

The Critical Packing Parameter (CPP) is a crucial metric in surfactant science that predicts how molecules arrange themselves based on tail volume, head area, and tail length, aiding applications from detergents to drug delivery. Understanding CPP helps forecast molecular behavior...

High-Density Polyethylene (HDPE) is a durable, versatile thermoplastic with a high strength-to-density ratio used in packaging, construction, and various other applications due to its resistance to impact and chemicals. HDPE's production involves polymerization of ethylene gas using different methods that...

The Harmonized System (HS) code is a universal classification system for goods in international trade, essential for identifying packaging materials and ensuring compliance with regulations. Accurate HS codes facilitate customs processes, determine tariffs, and are crucial to avoid legal issues...

The pharmaceutical packaging HS code is essential for global trade, ensuring regulatory compliance, accurate tariff calculations, and efficient customs clearance. Understanding and correctly using the HS code helps businesses avoid delays, fines, and ensures smooth international operations by accurately classifying...

The environmental footprint of packaging is a complex issue involving the entire lifecycle from raw material extraction to disposal, with plastics contributing significantly to global warming and pollution. Strategies for reduction include resource efficiency, recycling technology advancements, renewable materials usage,...

Bulk packaging is a crucial component of logistics, focusing on efficiency and cost-saving by using large containers like IBCs, drums, and pail buckets to transport substantial quantities of goods safely. It involves selecting the right materials—such as fiberboard boxes or...

Fumigation is essential for packaging materials, especially wood, to prevent pest infestations that threaten ecosystems and economies; it ensures compliance with global phytosanitary standards. It's crucial in the supply chain to maintain product integrity and adhere to international trade regulations...

Pharmaceutical packaging certification is essential for ensuring product safety and efficacy, complying with legal standards, building consumer trust, and encouraging innovation despite potential costs and regulatory challenges....

Reusable packaging promotes sustainability by reducing waste and encouraging a circular economy, with benefits including resource efficiency and reduced environmental impact. Regulatory incentives are fostering this shift towards reusability, which offers economic advantages alongside fulfilling global responsibility. The environmental benefits of...

Hazardous materials (Hazmat) are substances that can endanger health, property, or the environment and require specific handling and packaging to mitigate risks during transport. Regulatory bodies enforce strict guidelines for Hazmat transportation; non-compliance can result in severe consequences. Different types of...

Radioactive material packaging ensures safety during transport by containing radiation and preventing contamination. It involves understanding radioactivity levels, using shielding materials like lead or concrete, ensuring containment with robust seals, and adhering to strict regulations for different package types designed...

Rigid packaging materials like glass, metal, and certain plastics are chosen for their durability and protective qualities against external pressure. They offer advantages such as high strength and barrier properties but also have disadvantages including higher costs and sustainability concerns. Different...

Acids can damage packaging materials, leading to product and environmental harm; understanding their chemical interactions is vital for creating acid-resistant solutions. Acid-resistant packaging ensures safety, maintains quality, and meets regulatory standards by preventing leakage and contamination of acidic products....