Drop test

Drop test

Drop Test

A drop test is a crucial method used in the packaging industry to ensure that products can withstand impacts during shipping and handling. This test involves dropping a packaged item from a specific height to see if it remains intact and undamaged.

Why is a Drop Test Important?

The main goal of a drop test is to simulate real-world conditions. Packages often get dropped during transit. A drop test helps identify weak points in the packaging. This ensures that the product inside stays safe.

How is a Drop Test Conducted?

To perform a drop test, you need a controlled environment. The package is dropped from a predetermined height. The height varies based on the type of product and packaging. After the drop, the package is inspected for damage.

Types of Drop Tests

There are different types of drop tests. The most common are free-fall, rotational, and edge drop tests. Each type targets different aspects of the packaging's durability.

Standards and Regulations

Several organizations set standards for drop tests. These include ASTM, ISTA, and ISO. Following these standards ensures consistency and reliability in testing.

Benefits of Drop Testing

Conducting a drop test offers many benefits. It helps reduce product returns due to damage. It also improves customer satisfaction by ensuring the product arrives in perfect condition.

Blog Posts with the term: Drop test

Packaging hazards pose risks to product safety during transportation and storage, stemming from physical damage, environmental conditions, and human error; addressing these requires a comprehensive design strategy. Shipping hazards are categorized into shock damage, vibrations, compression forces, and atmospheric conditions;...

Amazon's packaging evolution reflects its commitment to innovation, sustainability, and customer satisfaction through initiatives like Frustration-Free Packaging, which reduces waste and enhances the unboxing experience. By leveraging eco-friendly materials, AI-driven optimization, and scalable solutions across product categories, Amazon has set...

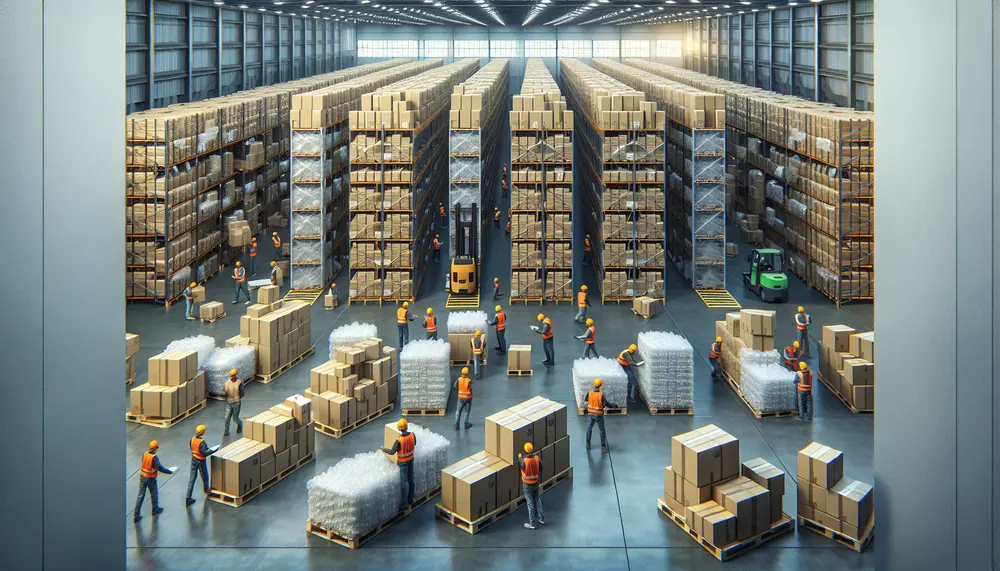

Protective packaging and materials handling are essential in logistics to ensure products reach their destination undamaged, optimizing efficiency and reducing costs. By implementing best practices such as choosing the right materials, using cushioning, securing packaging, clear labeling, testing packaging durability,...

Packaging engineering is a crucial field that combines science, technology, and design to create packaging solutions ensuring product safety, quality, and appeal across various industries. Packaging engineers are responsible for designing practical and attractive packaging, selecting sustainable materials, ensuring compliance...

Package design engineering combines elements of engineering, design, and marketing to create packaging that protects products while enhancing their appeal and functionality. Key skills for package design engineers include technical proficiency, problem-solving abilities, attention to detail, creativity, communication skills, and...

Packaging engineering combines science, technology, and creativity to develop functional and cost-effective packaging solutions that meet regulatory standards while enhancing product appeal; engineers must balance material selection, design innovation, environmental impact, and compliance with industry requirements....

Jelly cases stand out for their blend of flexibility, durability, and style, crafted from materials like TPU or silicone that provide shock absorption and a snug fit. They offer lightweight protection with customizable designs but may attract dust or yellow...

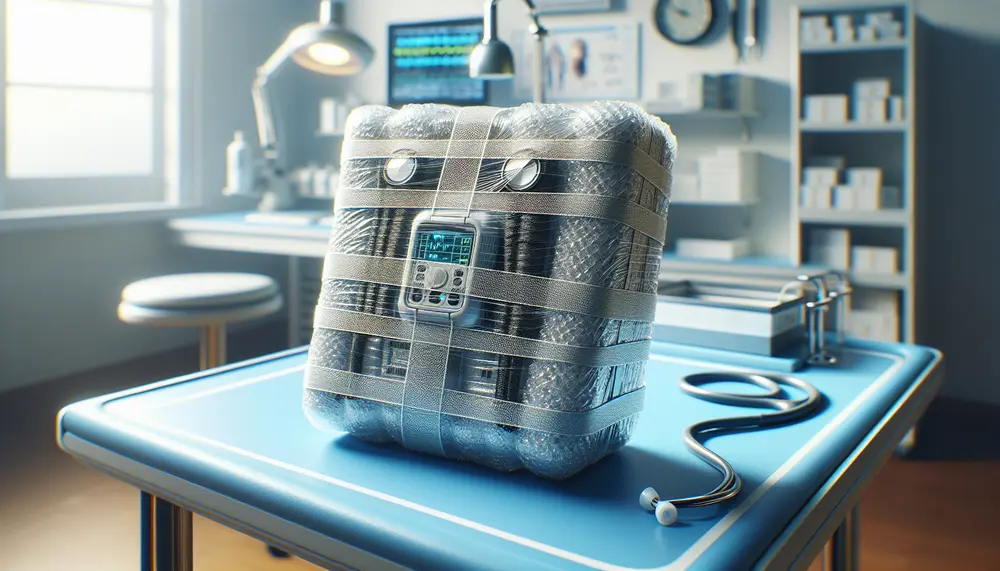

Protective packaging for medical devices is essential to ensure their safety, integrity, and sterility during transportation and storage. It involves selecting appropriate materials that can withstand sterilization processes while providing physical protection and maintaining regulatory compliance....

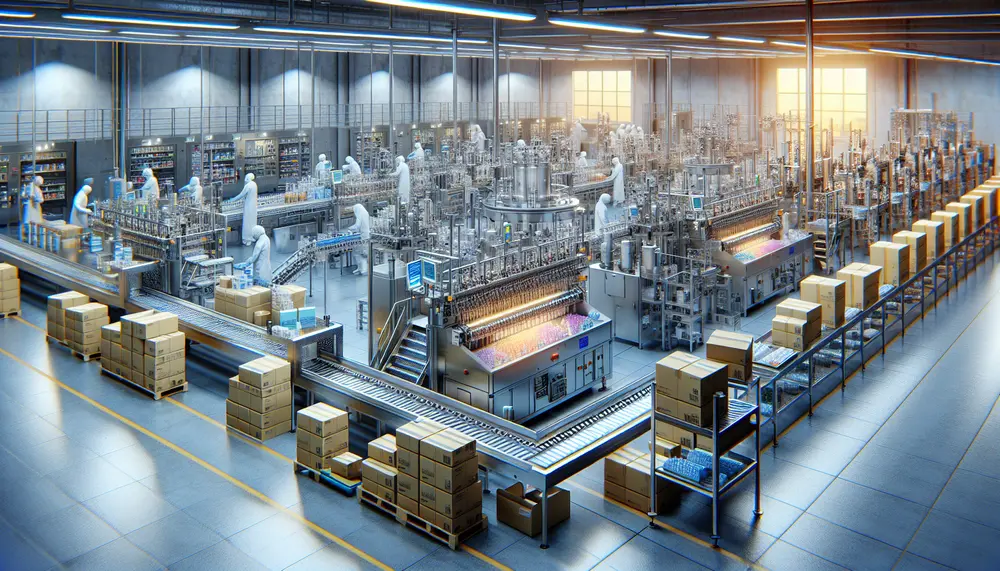

The pharmaceutical packaging value chain is essential for ensuring medications are safely delivered from manufacturers to patients, involving steps like design and development, material selection, manufacturing processes, quality control, distribution logistics, regulatory compliance, and sustainability. Each component plays a crucial...

Radioactive material packaging ensures safety during transport by containing radiation and preventing contamination. It involves understanding radioactivity levels, using shielding materials like lead or concrete, ensuring containment with robust seals, and adhering to strict regulations for different package types designed...

Protective packaging products are essential for safeguarding items during transit, storage, and handling by providing a buffer against damage from impacts, vibrations, moisture, and temperature fluctuations. This article explores various types of protective packaging such as bubble wrap, foam packaging,...

Protecting products during storage and transport is crucial in manufacturing, requiring the right protective packaging materials to save time, money, and prevent damage. This article explores various types of protective packaging such as foam, bubble wrap, corrugated cardboard, air pillows,...

Product packaging is essential for protection, communication, and marketing; it must align with the product's physical needs and brand identity. Effective design balances visual appeal, functionality, user experience, and market demands to differentiate products. Choosing the right materials involves considering protection...

Protective packaging solutions are essential for safeguarding products during transit and storage, preventing damage from physical impacts and environmental factors. Effective protective packaging reduces costs associated with damaged goods, enhances customer satisfaction, improves brand reputation, and ensures compliance with industry...

Protective packaging is crucial for ensuring products reach customers in perfect condition, reducing damage and enhancing satisfaction. By choosing the right materials like bubble wrap, foam, or corrugated cardboard based on product characteristics and shipping conditions, businesses can optimize their...