Table of Contents:

Introduction

The pharmaceutical packaging value chain is a complex and vital part of the healthcare industry. It ensures that medications are safely delivered from manufacturers to patients. Understanding this value chain helps in appreciating the various steps involved in creating effective and safe packaging solutions. This article will guide you through the different components of the pharmaceutical packaging value chain, highlighting their importance and the challenges faced in the industry.

The Importance of Pharmaceutical Packaging

Pharmaceutical packaging plays a crucial role in the healthcare industry. It serves multiple purposes, ensuring that medications are protected, effective, and safe for patient use. Here are some key reasons why pharmaceutical packaging is important:

- Protection: Packaging shields medications from environmental factors such as moisture, light, and temperature fluctuations. This helps maintain the stability and efficacy of the drugs.

- Safety: Proper packaging prevents contamination and tampering, ensuring that the medication remains safe for consumption. Child-resistant packaging also helps prevent accidental ingestion by children.

- Compliance: Packaging includes essential information such as dosage instructions, expiration dates, and warnings. This helps patients use the medication correctly and safely.

- Convenience: User-friendly packaging designs, such as blister packs and pre-filled syringes, make it easier for patients to handle and administer their medications.

- Branding: Packaging serves as a communication tool for pharmaceutical companies, helping to build brand recognition and trust among consumers.

By fulfilling these roles, pharmaceutical packaging ensures that medications are delivered to patients in the best possible condition, ultimately contributing to better health outcomes.

Pros and Cons of the Pharmaceutical Packaging Value Chain

| Aspect | Pros | Cons |

|---|---|---|

| Regulatory Compliance |

|

|

| Cost Management |

|

|

| Technological Advancements |

|

|

| Sustainability |

|

|

| Supply Chain Management |

|

|

| Customization |

|

|

Components of the Pharmaceutical Packaging Value Chain

The pharmaceutical packaging value chain consists of several interconnected components. Each component plays a vital role in ensuring that medications are safely and effectively delivered to patients. Here are the main components of this value chain:

- Design and Development: This initial stage involves creating packaging designs that meet regulatory requirements and protect the medication. It includes considerations for materials, functionality, and user-friendliness.

- Material Selection: Choosing the right materials is crucial for ensuring the packaging's durability and effectiveness. Materials must be compatible with the medication and provide adequate protection against environmental factors.

- Manufacturing Processes: This stage involves the actual production of the packaging. It includes various processes such as molding, printing, and assembly, ensuring that the packaging meets quality standards.

- Quality Control and Assurance: Rigorous testing and inspection are conducted to ensure that the packaging meets all safety and quality standards. This step is essential for preventing defects and ensuring the packaging's reliability.

- Distribution and Logistics: Once the packaging is produced, it must be efficiently distributed to pharmacies, hospitals, and other healthcare providers. This involves managing supply chains and ensuring timely delivery.

- Regulatory Compliance: Pharmaceutical packaging must comply with various regulations and standards set by health authorities. This includes labeling requirements, safety features, and documentation.

- Sustainability: Increasingly, there is a focus on making pharmaceutical packaging more environmentally friendly. This involves using recyclable materials and reducing waste.

Understanding these components helps in appreciating the complexity and importance of the pharmaceutical packaging value chain. Each step is crucial for ensuring that medications are delivered safely and effectively to patients.

Design and Development

The design and development phase is the foundation of the pharmaceutical packaging value chain. It involves creating packaging solutions that meet the specific needs of the medication and the end-user. Here are the key aspects of this phase:

- Understanding Requirements: The first step is to understand the specific requirements of the medication. This includes factors like dosage form, stability, and storage conditions. For example, some medications may need protection from light, while others require moisture barriers.

- Innovative Design: Packaging designers work on creating innovative solutions that enhance usability and safety. This can include features like child-resistant caps, tamper-evident seals, and easy-to-open designs for elderly patients.

- Material Compatibility: Selecting materials that are compatible with the medication is crucial. The materials must not react with the drug and should provide the necessary protection. For instance, blister packs are often used for tablets to protect them from moisture and contamination.

- Prototyping and Testing: Before mass production, prototypes of the packaging are created and tested. This helps in identifying any potential issues and making necessary adjustments. Testing can include stress tests, drop tests, and stability tests to ensure the packaging performs well under various conditions.

- Regulatory Considerations: The design must comply with regulatory standards set by health authorities. This includes proper labeling, safety features, and documentation. Designers must stay updated with the latest regulations to ensure compliance.

By focusing on these aspects, the design and development phase ensures that the packaging not only protects the medication but also enhances the overall user experience. This phase sets the stage for the subsequent steps in the pharmaceutical packaging value chain.

Material Selection

Material selection is a critical step in the pharmaceutical packaging value chain. The right materials ensure that the packaging effectively protects the medication and meets regulatory standards. Here are the key considerations in material selection:

- Compatibility: The chosen materials must be compatible with the medication. They should not react with the drug or affect its stability. For example, certain plastics are used for liquid medications because they do not interact with the liquid.

- Barrier Properties: Materials must provide adequate barriers against environmental factors such as moisture, light, and oxygen. For instance, aluminum foil is often used in blister packs because it offers excellent moisture and light protection.

- Durability: The materials must be durable enough to withstand handling, transportation, and storage. This ensures that the packaging remains intact and the medication is protected until it reaches the patient.

- Regulatory Compliance: Materials must meet the regulatory standards set by health authorities. This includes being non-toxic and safe for use in pharmaceutical applications. Compliance with regulations like the FDA in the United States or EMA in Europe is essential.

- Sustainability: Increasingly, there is a focus on using sustainable materials to reduce environmental impact. This includes using recyclable or biodegradable materials. For example, some companies are exploring the use of plant-based plastics.

By carefully selecting materials based on these considerations, pharmaceutical companies can ensure that their packaging provides the necessary protection and complies with all relevant regulations. This step is crucial for maintaining the quality and safety of the medication throughout its shelf life.

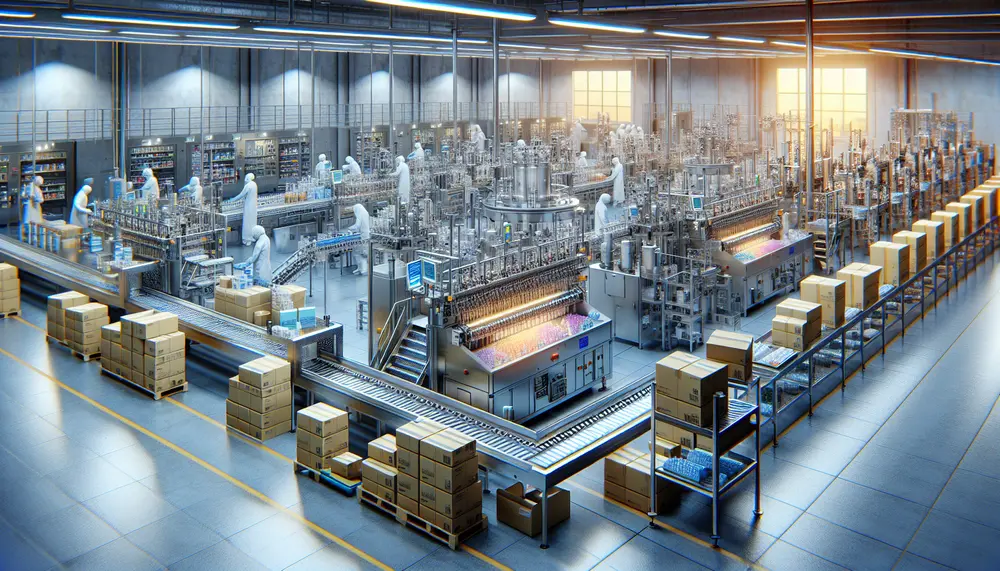

Manufacturing Processes

The manufacturing processes in the pharmaceutical packaging value chain are essential for producing high-quality packaging that meets all safety and regulatory standards. This phase involves several key steps:

- Molding and Forming: This step involves shaping the raw materials into the desired packaging forms. Techniques such as injection molding, blow molding, and thermoforming are commonly used. For example, plastic bottles for liquid medications are often created using blow molding.

- Printing and Labeling: Accurate and clear labeling is crucial for pharmaceutical packaging. This step involves printing essential information such as dosage instructions, expiration dates, and regulatory compliance details. Advanced printing technologies ensure high-quality and durable labels.

- Assembly: After molding and printing, the packaging components are assembled. This can include attaching caps to bottles, sealing blister packs, or assembling multi-part packaging systems. Automation is often used to ensure precision and efficiency.

- Quality Control: Rigorous quality control measures are implemented throughout the manufacturing process. This includes inspecting the packaging for defects, conducting stress tests, and ensuring that all components meet the required standards. Quality control helps in identifying and rectifying issues before the packaging reaches the market.

- Scalability: The manufacturing processes must be scalable to meet varying production demands. This involves optimizing production lines and using flexible manufacturing systems that can adapt to different packaging requirements.

By focusing on these manufacturing processes, pharmaceutical companies can produce packaging that is both high-quality and compliant with all regulatory standards. This ensures that the medication is protected and safe for patient use, maintaining the integrity of the pharmaceutical packaging value chain.

Quality Control and Assurance

Quality control and assurance are critical components of the pharmaceutical packaging value chain. They ensure that the packaging meets all safety, regulatory, and performance standards. Here are the key aspects of quality control and assurance:

- Inspection: Every batch of packaging undergoes thorough inspection to identify any defects or inconsistencies. This includes visual inspections and automated systems that check for flaws such as cracks, leaks, or misprints.

- Testing: Various tests are conducted to ensure the packaging can withstand different conditions. These tests include stress tests, drop tests, and environmental tests to check the packaging's durability and barrier properties. For example, blister packs may be subjected to moisture tests to ensure they protect the medication effectively.

- Compliance Verification: Packaging must comply with regulatory standards set by health authorities. This involves verifying that all labeling, safety features, and documentation meet the required guidelines. Compliance checks are conducted at multiple stages of the production process.

- Documentation: Detailed records are maintained for every batch of packaging produced. This documentation includes test results, inspection reports, and compliance certificates. Proper documentation ensures traceability and accountability, which are crucial for regulatory audits.

- Continuous Improvement: Quality control is an ongoing process. Feedback from inspections and tests is used to make continuous improvements in the packaging design and manufacturing processes. This helps in maintaining high standards and adapting to new regulatory requirements.

By implementing rigorous quality control and assurance measures, pharmaceutical companies can ensure that their packaging is safe, reliable, and compliant with all relevant standards. This step is essential for maintaining the integrity of the pharmaceutical packaging value chain and ensuring patient safety.

Distribution and Logistics

Distribution and logistics are vital components of the pharmaceutical packaging value chain. They ensure that the packaged medications reach healthcare providers and patients efficiently and safely. Here are the key aspects of distribution and logistics:

- Supply Chain Management: Effective supply chain management ensures that the packaging materials and finished products are available when needed. This involves coordinating with suppliers, manufacturers, and distributors to maintain a steady flow of materials and products.

- Warehousing: Proper storage conditions are crucial for maintaining the integrity of pharmaceutical packaging. Warehouses must be equipped to handle temperature-sensitive products and provide protection against environmental factors such as humidity and light.

- Transportation: The transportation of pharmaceutical products requires careful planning and execution. This includes selecting appropriate transportation methods and routes to ensure timely delivery. For temperature-sensitive medications, refrigerated transport may be necessary to maintain product stability.

- Tracking and Traceability: Advanced tracking systems are used to monitor the movement of pharmaceutical products throughout the supply chain. This ensures traceability and helps in identifying and addressing any issues that may arise during transportation. Technologies such as RFID and GPS are commonly used for this purpose.

- Regulatory Compliance: The distribution and logistics processes must comply with regulatory requirements. This includes adhering to guidelines for the transportation and storage of pharmaceutical products. Compliance ensures that the products remain safe and effective until they reach the end-user.

By focusing on these aspects, pharmaceutical companies can ensure that their products are distributed efficiently and safely. Effective distribution and logistics are essential for maintaining the integrity of the pharmaceutical packaging value chain and ensuring that patients receive their medications in optimal condition.

Regulatory Compliance

Regulatory compliance is a cornerstone of the pharmaceutical packaging value chain. It ensures that packaging meets all legal and safety standards set by health authorities. Here are the key aspects of regulatory compliance:

- Adherence to Guidelines: Pharmaceutical packaging must adhere to guidelines set by regulatory bodies such as the FDA (Food and Drug Administration) in the United States and the EMA (European Medicines Agency) in Europe. These guidelines cover aspects like labeling, safety features, and material specifications.

- Labeling Requirements: Accurate and clear labeling is essential for regulatory compliance. Labels must include critical information such as dosage instructions, expiration dates, batch numbers, and safety warnings. This ensures that patients and healthcare providers have all the necessary information to use the medication safely.

- Safety Features: Packaging must incorporate safety features to prevent tampering and ensure child resistance. Tamper-evident seals and child-resistant caps are common requirements. These features help in protecting the medication from unauthorized access and accidental ingestion.

- Documentation and Record-Keeping: Comprehensive documentation is required to demonstrate compliance with regulatory standards. This includes maintaining records of quality control tests, inspection reports, and compliance certificates. Proper documentation ensures traceability and accountability.

- Regular Audits and Inspections: Regulatory bodies conduct regular audits and inspections to ensure compliance. Pharmaceutical companies must be prepared for these audits by maintaining high standards and keeping detailed records. Non-compliance can result in penalties and product recalls.

By focusing on regulatory compliance, pharmaceutical companies can ensure that their packaging meets all legal and safety standards. This is essential for maintaining the integrity of the pharmaceutical packaging value chain and ensuring patient safety.

Sustainability in Pharmaceutical Packaging

Sustainability in pharmaceutical packaging is becoming increasingly important as the industry seeks to reduce its environmental impact. Here are the key aspects of sustainability in this context:

- Eco-Friendly Materials: One of the primary ways to enhance sustainability is by using eco-friendly materials. This includes biodegradable plastics, recycled materials, and plant-based alternatives. For example, some companies are exploring the use of bioplastics derived from corn starch.

- Reduction of Waste: Minimizing waste during the packaging process is crucial. This can be achieved by optimizing packaging designs to use fewer materials and by implementing efficient manufacturing processes. Reducing waste not only benefits the environment but also lowers production costs.

- Recyclability: Designing packaging that is easy to recycle is another important aspect of sustainability. Clear labeling on how to recycle the packaging and using materials that are widely accepted by recycling programs can help improve recyclability rates.

- Energy Efficiency: Implementing energy-efficient practices in the manufacturing process can significantly reduce the carbon footprint of pharmaceutical packaging. This includes using renewable energy sources and optimizing machinery to consume less power.

- Regulatory Compliance: Sustainability efforts must also comply with regulatory standards. This includes adhering to guidelines for the use of sustainable materials and ensuring that eco-friendly packaging still meets all safety and quality requirements.

By focusing on these aspects, pharmaceutical companies can make significant strides in reducing their environmental impact. Sustainability in pharmaceutical packaging not only benefits the planet but also meets the growing demand from consumers and regulatory bodies for more eco-friendly solutions.

Challenges and Opportunities

The pharmaceutical packaging value chain faces several challenges, but these also present opportunities for innovation and improvement. Here are some of the key challenges and opportunities in this field:

- Regulatory Complexity: Navigating the complex regulatory landscape is a significant challenge. Different regions have varying requirements, making compliance a complex task. However, this also presents an opportunity for companies to develop robust compliance systems and gain a competitive edge by ensuring global regulatory adherence.

- Cost Management: The cost of high-quality materials and advanced manufacturing processes can be high. Balancing cost with quality and compliance is a constant challenge. Companies that can innovate to reduce costs without compromising on quality will find significant opportunities for growth.

- Technological Advancements: Rapid advancements in technology, such as smart packaging and digital printing, offer new opportunities but also require significant investment and adaptation. Embracing these technologies can lead to more efficient processes and enhanced product offerings.

- Sustainability Demands: The push for more sustainable packaging solutions is both a challenge and an opportunity. Developing eco-friendly materials and processes can be costly and complex, but it also opens up new markets and meets consumer demand for sustainable products.

- Supply Chain Disruptions: Global supply chain disruptions, such as those caused by the COVID-19 pandemic, pose significant challenges. However, these disruptions also highlight the need for more resilient and flexible supply chains, presenting opportunities for companies to innovate and improve their logistics strategies.

- Customization and Personalization: The growing demand for personalized medicine requires customized packaging solutions. This presents a challenge in terms of scalability and cost but also offers opportunities for companies to differentiate themselves by providing tailored packaging solutions.

By addressing these challenges and leveraging the opportunities they present, pharmaceutical companies can enhance their packaging value chain. This not only improves efficiency and compliance but also meets the evolving needs of the market and contributes to better patient outcomes.

Conclusion

Understanding the pharmaceutical packaging value chain is essential for ensuring the safe and effective delivery of medications. Each component, from design and development to distribution and logistics, plays a crucial role in maintaining the integrity of pharmaceutical products. By focusing on key aspects such as material selection, manufacturing processes, quality control, regulatory compliance, and sustainability, companies can create packaging solutions that meet the highest standards.

While the industry faces several challenges, including regulatory complexity and cost management, these also present opportunities for innovation and improvement. Embracing technological advancements, developing eco-friendly materials, and enhancing supply chain resilience can lead to significant benefits for both companies and patients.

In conclusion, a well-managed pharmaceutical packaging value chain not only ensures compliance and safety but also contributes to better health outcomes. By continuously improving and adapting to new challenges, the industry can meet the evolving needs of the market and provide high-quality, reliable packaging solutions.

FAQ on Pharmaceutical Packaging Value Chain

What is the importance of pharmaceutical packaging?

Pharmaceutical packaging is crucial for protecting medications from environmental factors like moisture and light, ensuring their stability and effectiveness, preventing contamination, providing essential usage information, and enhancing convenience and branding for users.

What are the main components of the pharmaceutical packaging value chain?

The main components of the pharmaceutical packaging value chain include design and development, material selection, manufacturing processes, quality control and assurance, distribution and logistics, regulatory compliance, and sustainability.

How does material selection impact pharmaceutical packaging?

Material selection is critical for ensuring packaging durability, compatibility with medications, regulatory compliance, and environmental impact. The right materials protect against moisture, light, and other environmental factors while ensuring the safety and efficacy of the medication.

What are the challenges and opportunities in the pharmaceutical packaging value chain?

Challenges include regulatory complexity, cost management, and supply chain disruptions. However, opportunities lie in technological advancements, customization, sustainability initiatives, and developing robust compliance systems to gain a competitive edge.

Why is quality control important in pharmaceutical packaging?

Quality control ensures that packaging meets safety, regulatory, and performance standards by conducting rigorous inspections and tests, maintaining documentation, and enabling continuous improvement. This step is essential for patient safety and regulatory compliance.