Table of Contents:

Understanding the Role of Packaging Zips

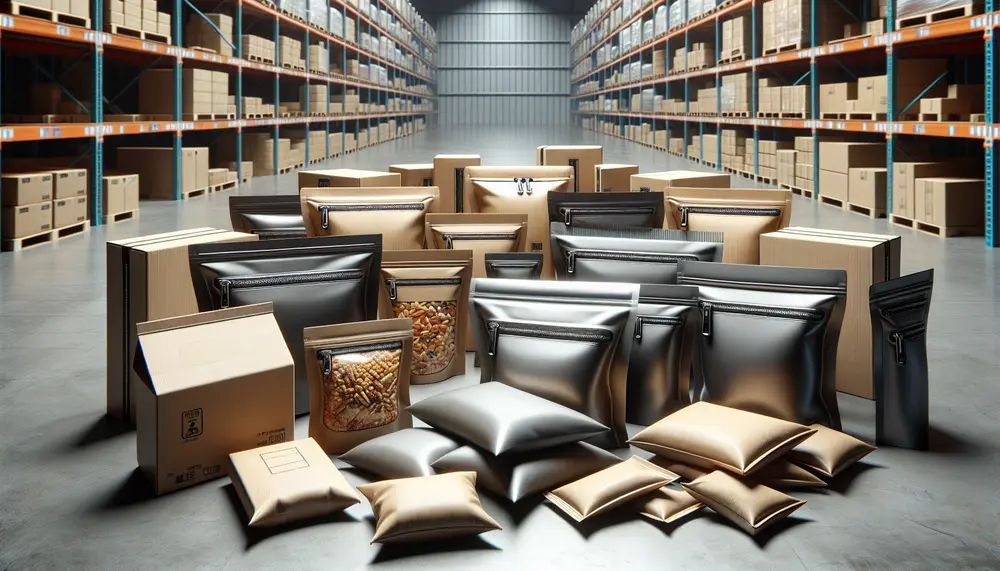

Packaging zips, also commonly known as zip locks or zipper closures, play a pivotal role in the world of packaging. Zips have revolutionized the way we secure products, offering a reliable sealing mechanism that consumers can easily open and close multiple times. This functionality extends the life of a product by guarding against contaminants and preserving freshness.

Zips are especially prominent in the realm of food packaging, where maintaining a hermetic seal can be the difference between a product staying fresh or spoiling prematurely. But their application doesn't stop there; they’re also used in pharmaceuticals, apparel, and electronics, proving their wide-reaching impact across various industries.

The introduction of packaging zip bags has been a game changer in terms of convenience and consumer satisfaction. These handy bags can be made transparent for easy identification of contents, and are often designed to be reusable, ticking the boxes for both practicality and environmental considerations.

Understanding this role is essential for any packaging professional or business looking to enhance their product's accessibility and shelf life through secure and user-friendly packaging solutions.

Exploring the Versatility of Zip Packaging Solutions

Zip packaging solutions offer an array of advantages that cater to diverse packaging requirements across different markets. The ingenuity behind zip technology allows these solutions to be tailored for a variety of sizes, ranging from small pouches ideal for individual snack servings to large bags designed for bulk storage. This scalability demonstrates the flexibility of packaging zips to suit any product dimension.

In addition to size customization, zips cater to a spectrum of material needs as well. Materials used for zip packaging can vary from highly durable plastics that protect electronics from static and moisture, to softer, more pliable varieties used in clothing or linen packaging, showcasing the functionality across various textures and durability requirements.

The ease of use provided by packaging zips is another aspect of their versatility. Whether it's a slider or press-to-close mechanism, users of all ages find zip closures manageable, contributing to a positive user experience.

Furthermore, the versatility of the zip mechanism lends itself to innovative applications. For instance, some packaging zips include a double seal feature for added assurance, while others might feature a tear notch for initial opening, combining convenience with security.

A significant aspect of the versatility of zips lies in their ability to be used multiple times, indicated by the term 're-sealable'. In comparison to one-time adhesives or seals, the re-usability of zips contributes to less waste and more value for the consumer.

"Zips provide an elegant solution to modern packaging needs, merging efficiency with enhanced user engagement." — Packaging Expert

Advantages and Challenges of Zip Packaging

| Pros of Zip Packaging | Cons of Zip Packaging |

|---|---|

| Easy to use and reseal | Higher cost than simple bag closures |

| Enhances product freshness | Potential for zipper to fail if not properly used |

| Convenient for portion control | Might be difficult to recycle depending on materials used |

| Provides a secure seal to protect contents | Added complexity in packaging production |

| Ideal for on-the-go products and consumer convenience | Can be challenging to open for those with limited dexterity |

The Security Benefits of Using Zips in Packaging

The integration of zips into packaging designs brings substantial security benefits that are key in protecting the integrity of the product. Packaging zips act as a barrier against external contaminants such as dust, moisture, and insects, which can compromise the quality and safety of the packaged goods.

Furthermore, packaging zips offer tamper evidence, an essential feature for food safety and pharmaceuticals. Once the seal is broken, it is immediately obvious, thus alerting consumers to potential tampering or unauthorized access.

Packaging zips also contribute to product safety during transit. The secure seal reduces the risk of spillage and ensures that products remain contained and in excellent condition throughout the distribution chain.

For products requiring strict compliance with safety regulations, packaging zips can be engineered to meet industry-specific standards. This includes creating child-resistant zips for products that could harm children if accidentally ingested or making zips that are robust enough to withstand extreme environmental conditions.

Packaging zips are considered a deterrent against product theft as well. A re-sealable zip is often more difficult to open discreetly than other forms of closures, which can be easily pierced or torn open. This helps to maintain product integrity in retail environments where pilferage is a concern.

In summary, the security advantages of utilizing zips in packaging underscore the value they bring in protecting products from production to consumption. By incorporating zips into packaging solutions, manufacturers can ensure greater product safety and consumer trust.

Packaging Zip Bags: Combining Convenience and Durability

Packaging zip bags strike an impressive balance between ease-of-use and long-lasting performance. These bags often consist of resilient materials that stand up to the rigors of frequent handling and usage without compromising their structural integrity. With a typical strength of around 45 micrometers, these bags are robust enough to resist punctures and tears, preserving the contents within.

The convenience factor is echoed in the user-centric design of zipper closures, which enable quick access while maintaining the freshness of goods. Users appreciate the minimal effort required to open and securely reseal the bag, a process so simple yet effective that it substantially enhances the overall consumer experience.

Specifically, POLLAST!C Ziplock Bags demonstrate these qualities effectively. They come in various sizes to accommodate different product volumes, with options like 100 x 85 mm, 200 x 195 mm, and 355 x 255 mm, providing a range of choices for different packaging needs.

Noteworthy as well is the environmental consciousness these bags convey, being composed of at least 70% recycled Ocean Bound Plastic. Their design promotes not only reuse but also encourages responsible disposal under suitable conditions for soft plastics recycling, aligning with eco-friendly practices.

Moreover, the clarity of these zip bags benefits both retailers and consumers. The transparent nature allows for easy identification of contents, minimizing the need for additional labeling and enabling quick stock management and customer selection.

"Packaging zip bags embody a synergy of user convenience and enduring quality, confirming their status as a staple in modern packaging solutions." — Sustainability Advocate

Innovative Uses of Zips in Product Packaging

The world of packaging is constantly evolving, and zips play a key role in driving innovation within the industry. One of the more creative uses of zips in product packaging is their integration into multi-compartment bags. These bags take advantage of zips to separate different ingredients or components, which can be mixed by the consumer just before use, ensuring maximum freshness and potency.

Another groundbreaking application of zips is seen in the medical field, where sterile packaging with zip closures is utilized. This type of packaging maintains the sterility of medical instruments or supplies until the moment they are needed, which is critical in medical procedures.

Moreover, zips have found a place in the smart packaging domain. Packaging with built-in zip closures can include integrated sensors that track temperature or exposure to certain conditions, with the zip acting as an additional layer of protection against environmental factors that might trigger these sensors.

In the apparel sector, reusable zip bags have transformed packaging into a part of the product experience. Not only do they protect the items during shipping, but customers can also use them for storage or travel, adding value beyond the initial purchase.

Zips are also making waves in the realm of child-safe packaging. Certain products require packaging that is difficult for children to open, and zips can be engineered to include safety features that present an extra challenge to young hands, thereby reducing accidental access to potentially harmful products.

"The adoption of zip technology in diverse packaging applications exemplifies the innovative spirit of the industry, fulfilling consumer and manufacturer needs with equal finesse." — Packaging Innovator

The Environmental Impact of Packaging Zips

The conversation around packaging zips and their environmental impact is multi-faceted. On one hand, zips enhance the lifespan and utility of bags, leading to potentially lower consumption rates of single-use packaging. On the other, the materials used in zip production are often derived from plastic, which raises concerns about their end-of-life disposal and contribution to global plastic waste.

Manufacturers address these concerns by investing in eco-friendly materials. For instance, there's a growing trend towards using recycled plastics in the production of zips. In the case of POLLAST!C Ziplock Bags, they incorporate a significant proportion of recycled Ocean Bound Plastic, which not only reduces reliance on virgin plastics but also helps tackle the issue of marine waste.

Moreover, the reusability of zip bags promotes a circular economy, where products are recycled or repurposed rather than discarded. The BSCI certification of production facilities, as seen with POLLAST!C, ensures that manufacturing processes align with social responsibility and environmental protection standards.

Ensuring the recyclability of zip bags at their lifecycle's end must be a key consideration, encouraging consumers to divert them away from landfills. This is addressed by facilitating the recycling of soft plastics, depending on the availability of relevant recycling programs which can vary by region.

Additionally, brands committed to sustainability, like those that are BCorp certified or members of the Carbon Fund, offer packaging solutions that boast both functional and environmental benefits. These certifications represent a company's ongoing commitment to sustainability and carbon footprint reduction.

"By opting for packaging zips made from recycled and recyclable materials, we can minimize the environmental impact without compromising the protective qualities that make them so valuable." — Environmental Advocate

Choosing the Right Packaging Zip for Your Needs

Selecting the appropriate packaging zip is crucial for ensuring that your product receives the optimal level of protection and functionality. The decision-making process involves considering a variety of factors, tailored to the specific requirements of the item being packaged.

The thickness of the zip bag, typically measured in micrometers (µm), is an important consideration. A thicker bag may offer superior protection for heavy or sharp items, while for lightweight items, a thinner bag might suffice.

The dimensions of the packaging zip bag must be adequate for the volume of the product, ensuring a snug fit without being overly tight or excessively roomy, which might compromise the contents or lead to material wastage.

For food products, selecting a packaging zip that is food-grade and free from harmful contaminants is non-negotiable. This safeguard ensures that the food remains safe for consumption throughout its shelf life.

If branding is a key component of your packaging strategy, consider packaging zips that allow for customization. Options may include printing capabilities or unique design features that enhance brand visibility and consumer appeal.

Finally, align your choice with your company's values, particularly concerning sustainability. Reflect on selecting packaging zips that are made from recycled materials, with clear instructions for consumers on how to dispose of or recycle the packaging responsibly post-use.

"The right packaging zip merges practical considerations with a company's ethos, leading to a solution that serves both product integrity and brand philosophy." — Packaging Consultant

Maintaining Product Freshness with Packaging Zips

One of the most significant advantages of utilizing packaging zips is their ability to maintain the freshness of products. Zips provide an airtight closure that helps to prevent the ingress of air and moisture, which are primary causes of spoilage and staleness.

When it comes to sensitive products like food items or pharmaceuticals, the quality of the seal is paramount. Packaging zips are engineered to create an intimate closure that blocks external factors from affecting the product's purity and quality. This often results in an extended shelf life and preserves the product's desirable properties such as crispness, moisture content, or medicinal efficacy.

For perishable goods, it is essential that the protective barrier provided by the packaging zip is both secure and easy to reseal after the initial opening. A high-quality zip ensures that the protective environment of the packaging can be restored quickly and effectively by the consumer, maintaining freshness for a subsequent use.

Moreover, the modular nature of zip packaging allows for portion control, where consumers can take out what they need and easily reseal the bag, ensuring the remaining product's exposure to air and humidity is minimized. This is not only practical but can also reduce food waste at the consumer level.

Additionally, packaging zips can support the precise control of environmental conditions for specialized products, such as those that require a controlled atmosphere. In these cases, zips may be used in tandem with absorbers or emitters that regulate gases like oxygen or carbon dioxide inside the packaging.

"Packaging zips are a key ally in the battle against product degradation, providing a simple yet sophisticated means of ensuring freshness from the shelf to the consumer's home." — Food Safety Specialist

Customizing Packaging Zips for Brand Enhancement

Customized packaging zips offer an outstanding opportunity for brand enhancement. By tailoring the design of zip closures, brands can create a distinctive visual and functional identity that resonates with customers and stands out in the marketplace.

Brand customization of packaging zips can include the integration of logos, brand colors, and patterns. This not only increases the aesthetic appeal but also reinforces brand recognition each time a customer interacts with the product.

Innovative brands might opt for custom-shaped zips that align with the company's image or the nature of the product. Such bespoke elements can transform the packaging zip into a unique touchpoint, enhancing the unboxing experience and deepening the brand's connection with its audience.

Another level of customization involves the functionality of the zip itself. Brands can work with manufacturers to develop specialized zip features, such as ergonomic designs for ease of opening or extra-secure locks for child safety, adding a practical edge to the brand's identity.

The potential for interactive elements should not be overlooked. Packaging zips that incorporate QR codes or NFC tags can act as gateways to digital content, further engaging customers and providing an avenue for additional marketing activities.

Lastly, customization extends to the commitment to sustainability. By choosing packaging zips made from eco-conscious materials and showcasing this choice through clear messaging on the packaging, brands can enhance their image as responsible and forward-thinking.

"Customizing packaging zips is a strategic move that imbues a product with distinctive character, catering to both the visual and functional preferences of today's discerning consumers." — Branding Expert

The Future of Packaging: Trends in Zip Technology

As we look ahead, the future of packaging continues to evolve with emerging trends in zip technology. Innovations are driven by both consumer demand and the need for sustainability, resulting in advancements that are shaping the packaging industry.

One such trend is the development of smart zips, which incorporate intelligent features like freshness indicators or time-temperature sensors. These technologies are poised to enhance the functionality of packaging, providing consumers with real-time information about the condition of their products.

Another notable trend is the exploration of biodegradable and compostable zip materials. As the packaging sector grapples with plastic waste, the demand for zips that break down in an eco-friendly manner is gaining traction. This shift aligns with a broader movement towards materials that offer a reduced environmental footprint.

Further advancements are being made in recycling-friendly zips. Efforts are underway to design zips that are easily separable from their packaging, allowing for more efficient material recovery and recycling processes.

The use of minimalist zips is also emerging as a trend, where the design focuses on reducing excess material without compromising on performance. These leaner designs support sustainability goals by lowering material use and, consequently, the carbon emissions associated with packaging production.

Moreover, the rise of e-commerce has fueled the demand for reinforced zip closures that can withstand the rigors of shipping and handling, ensuring products arrive at consumers' doors in pristine condition.

"The advancement of zip technology is a critical element in the ongoing quest for more efficient, user-friendly, and sustainable packaging solutions." — Packaging Technologist

FAQ: The Impact of Zip Technology on Secure and Versatile Packaging

What makes packaging zips so important for product security?

Packaging zips provide a barrier against contaminants, enhance product safety during transit, and offer tamper evidence. They ensure that products remain secure and in excellent condition from production to consumption.

Can packaging zip bags be customized for brand enhancement?

Yes, packaging zip bags can be customized with logos, brand colors, patterns, and even special functional features to enhance brand visibility and consumer appeal. This customization serves both visual and practical purposes, reinforcing brand identity.

How do packaging zips contribute to sustainability?

Packaging zips contribute to sustainability by promoting the reuse of bags, reducing waste, and supporting a circular economy. Manufacturers are increasingly using recycled materials like Ocean Bound Plastic to produce packaging zips, further minimizing environmental impact.

Are there different types of zip closures for various packaging needs?

Yes, there are various types of zip closures available, such as slider zips, press-to-close mechanisms, double-seal zips, and even child-resistant zips. These cater to a wide range of packaging requirements and ensure versatility across industries.

What is the role of packaging zips in maintaining product freshness?

Packaging zips play a crucial role in maintaining the freshness of perishable goods by providing an airtight seal. This prevents air and moisture from spoiling the product, thereby extending its shelf life and preserving its quality.