Table of Contents:

Introduction to Protective Cases with Foam

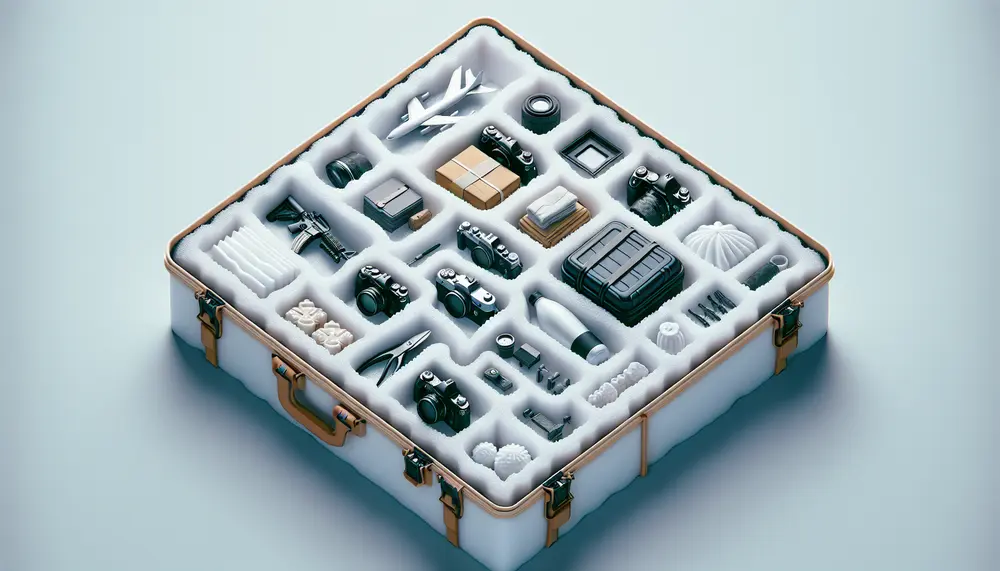

When it comes to safeguarding valuable items, a protective case with foam is an excellent choice. These cases are designed to offer maximum protection against impacts, vibrations, and other potential damages. The foam inside the case plays a crucial role in absorbing shocks and keeping the contents secure.

Protective cases with foam are widely used across various industries, from electronics to military applications. They provide a reliable solution for transporting and storing sensitive equipment. The foam inserts can be customized to fit the specific shape and size of the items, ensuring a snug and secure fit.

In this article, we will explore the benefits of using foam in protective cases, the different types of foam available, and how to choose the right case for your needs. Whether you are a beginner or an experienced professional, understanding the advantages of foam-lined cases can help you make informed decisions for optimal protection.

Why Use Foam in Protective Cases?

Foam is a critical component in protective cases for several reasons. Its primary function is to absorb shocks and cushion the contents of the case. This helps prevent damage from drops, impacts, and vibrations. Here are some key benefits of using foam in protective cases:

- Shock Absorption: Foam materials are excellent at absorbing and dissipating energy from impacts, reducing the risk of damage to the items inside.

- Custom Fit: Foam inserts can be cut and shaped to fit the specific dimensions of your items, ensuring they stay in place and are well-protected.

- Vibration Dampening: Foam helps to minimize the effects of vibrations during transport, which is crucial for sensitive equipment like electronics and instruments.

- Lightweight: Foam is lightweight, adding minimal weight to the case while providing maximum protection.

- Versatility: Different types of foam are available to suit various needs, from soft cushioning to rigid support.

By using foam in protective cases, you can ensure that your valuable items are safeguarded against a wide range of potential hazards. This makes foam-lined cases an ideal choice for transporting and storing delicate and expensive equipment.

Pros and Cons of Protective Cases with Foam

| Pros | Cons |

|---|---|

| Superior Shock Absorption | Can be Expensive |

| Customizable Fit | Foam May Wear Out Over Time |

| Effective Vibration Dampening | Requires Regular Inspection and Maintenance |

| Lightweight Yet Durable | May Not Be Suitable for All Environments |

| Versatile for Various Industries | Customization Can Be Time-Consuming |

Types of Foam Used in Protective Cases

Choosing the right type of foam for your protective case is essential for ensuring optimal protection. Different foams offer varying levels of cushioning, durability, and support. Here are some common types of foam used in protective cases:

- Polyurethane Foam: This foam is soft and flexible, making it ideal for cushioning delicate items. It provides excellent shock absorption and is often used for general-purpose protection.

- Polyethylene Foam: Known for its rigidity and durability, polyethylene foam is perfect for heavy-duty applications. It offers strong support and is resistant to chemicals and moisture.

- Cross-Linked Polyethylene Foam: This type of foam combines the benefits of polyethylene with added durability and a smoother surface. It is often used for high-end, custom cases.

- Convoluted Foam: Also known as egg-crate foam, this type features a textured surface that provides additional cushioning and air circulation. It is commonly used in lid inserts to keep items in place.

- Anti-Static Foam: Essential for protecting electronic components, anti-static foam prevents static electricity buildup that could damage sensitive equipment.

Each type of foam has its unique properties and is suited for different applications. Understanding these differences can help you select the best foam for your specific needs, ensuring that your items are well-protected during transport and storage.

Key Industries Benefiting from Protective Cases with Foam

Protective cases with foam are invaluable across various industries. Their ability to safeguard sensitive and valuable items makes them a preferred choice for many sectors. Here are some key industries that benefit significantly from using these cases:

- Electronics: The electronics industry relies heavily on protective cases with foam to transport and store delicate devices such as laptops, tablets, and cameras. The foam prevents damage from impacts and vibrations, ensuring the equipment remains functional.

- Military and Defense: In the military, protective cases with foam are used to transport weapons, communication devices, and other critical equipment. The foam provides the necessary shock absorption and durability required in harsh environments.

- Medical: Medical professionals use these cases to protect sensitive instruments and devices. Foam inserts ensure that medical equipment, such as diagnostic tools and surgical instruments, remain sterile and undamaged.

- Aerospace: The aerospace industry uses foam-lined cases to transport delicate components and tools. The foam helps to mitigate the effects of vibrations and impacts during flights.

- Photography and Videography: Photographers and videographers use protective cases with foam to carry cameras, lenses, and other accessories. The foam ensures that their expensive gear remains safe from shocks and drops.

These industries, among others, rely on the superior protection offered by foam-lined cases. The ability to customize the foam inserts to fit specific items makes these cases an essential tool for professionals who need to ensure the safety and integrity of their equipment.

How to Choose the Right Protective Case with Foam

Selecting the right protective case with foam involves considering several factors to ensure your items are well-protected. Here are some key points to keep in mind when making your choice:

- Item Dimensions: Measure the dimensions of the items you need to protect. Ensure the case and foam inserts can accommodate these measurements for a snug fit.

- Type of Foam: Choose the foam type based on the level of protection required. For delicate items, softer foam like polyurethane may be ideal. For heavier or more rugged items, consider polyethylene or cross-linked polyethylene foam.

- Durability: Assess the durability of both the case and the foam. Look for cases made from high-quality materials that can withstand harsh conditions.

- Customizability: Check if the foam inserts can be customized. Custom-cut foam provides a better fit and enhanced protection for your specific items.

- Portability: Consider the weight and design of the case. If you need to transport it frequently, opt for a lightweight case with comfortable handles or wheels.

- Environmental Resistance: Ensure the case offers resistance to water, dust, and chemicals if you will be using it in challenging environments.

- Security Features: Look for additional security features such as lockable latches or tamper-evident seals to protect valuable or sensitive items.

By considering these factors, you can choose a protective case with foam that meets your specific needs. This ensures that your items are not only well-protected but also easy to transport and use in various environments.

Top Brands Offering Protective Cases with Foam

Several top brands specialize in providing high-quality protective cases with foam. These brands are known for their durability, innovation, and reliability. Here are some of the leading names in the industry:

- Pelican: Pelican is renowned for its rugged and durable cases. They offer a wide range of sizes and configurations, with customizable foam inserts to fit various items. Pelican cases are often used in military, medical, and photography sectors.

- SKB: SKB provides a diverse selection of protective cases, including rack cases, shipping cases, and utility cases. Their foam inserts are designed to offer maximum protection for sensitive equipment, making them a popular choice in the music and aerospace industries.

- Gator: Gator cases are known for their versatility and robust construction. They offer solutions for musical instruments, audio equipment, and electronics, with foam inserts that can be tailored to specific needs.

- Nanuk: Nanuk cases are built to withstand extreme conditions. They feature high-impact resistant materials and customizable foam interiors, making them ideal for outdoor and industrial applications.

- Seahorse: Seahorse cases provide watertight and airtight protection. Their foam inserts can be customized to fit a variety of items, making them suitable for medical, military, and photography use.

- Underwater Kinetics: Known for their waterproof and dustproof cases, Underwater Kinetics offers solutions for diving, photography, and industrial applications. Their foam inserts ensure that items remain secure and protected.

These brands offer a range of protective cases with foam that cater to different needs and industries. By choosing a reputable brand, you can ensure that your items receive the best possible protection.

Case Study: Real-World Applications of Protective Cases with Foam

To understand the practical benefits of protective cases with foam, let's look at some real-world applications. These examples highlight how different industries use these cases to safeguard their valuable items.

Military Equipment Transport

The military often needs to transport sensitive equipment such as communication devices, weapons, and navigation tools. In one instance, a military unit used Pelican cases with custom-cut foam inserts to transport night vision goggles. The foam provided a snug fit, preventing movement and absorbing shocks during transit. This ensured the goggles arrived at their destination fully functional and undamaged.

Medical Device Protection

A medical equipment manufacturer needed to ship delicate diagnostic tools to hospitals worldwide. They chose SKB cases with anti-static foam to protect the electronic components from static discharge. The foam inserts were customized to fit each tool precisely, ensuring they remained secure and sterile during transport. This approach reduced damage rates and improved customer satisfaction.

Photography Gear Transport

A professional photographer frequently traveled for assignments and needed a reliable way to transport expensive cameras and lenses. They opted for Nanuk cases with convoluted foam in the lid and custom-cut foam in the base. The foam provided excellent cushioning and kept the gear organized. As a result, the photographer's equipment remained safe from impacts and vibrations, even during rough travels.

Aerospace Component Shipping

An aerospace company needed to ship sensitive components to various locations. They used Gator cases with cross-linked polyethylene foam for added durability. The foam inserts were designed to cradle each component, minimizing movement and protecting against shocks. This ensured the components arrived intact and ready for assembly.

These case studies demonstrate the versatility and effectiveness of protective cases with foam in various industries. By customizing the foam inserts to fit specific items, companies can ensure their valuable equipment remains safe and functional during transport and storage.

Maintenance Tips for Foam in Protective Cases

Proper maintenance of the foam in your protective case is essential to ensure long-lasting protection for your items. Here are some tips to help you keep the foam in top condition:

- Regular Inspection: Periodically check the foam for signs of wear and tear. Look for any cracks, tears, or compression that could compromise its protective qualities.

- Cleaning: Keep the foam clean by removing dust and debris. Use a vacuum cleaner with a soft brush attachment to gently clean the surface. Avoid using water or harsh chemicals, as they can damage the foam.

- Avoid Overloading: Do not overload the case with items that exceed its capacity. Overloading can compress the foam and reduce its ability to absorb shocks.

- Proper Storage: Store the case in a cool, dry place when not in use. Avoid exposing the foam to direct sunlight or extreme temperatures, as this can cause it to degrade over time.

- Replace When Necessary: If the foam shows significant signs of wear or damage, consider replacing it. Custom-cut foam inserts can be ordered to fit your specific case and items.

- Use Desiccants: To prevent moisture buildup, place desiccant packets inside the case. This is especially important for cases stored in humid environments.

By following these maintenance tips, you can extend the life of the foam in your protective case and ensure that it continues to provide optimal protection for your valuable items.

Conclusion: The Ultimate Protection Solution

Protective cases with foam offer an unparalleled level of security for a wide range of items. From delicate electronics to rugged military equipment, these cases provide the necessary cushioning and support to prevent damage during transport and storage.

The key benefits of using foam in protective cases include:

- Superior shock absorption

- Customizable fit for various items

- Effective vibration dampening

- Lightweight yet durable protection

By choosing the right type of foam and maintaining it properly, you can ensure that your valuable items remain safe and secure. Leading brands like Pelican, SKB, and Nanuk offer a variety of options to meet different needs, making it easier to find the perfect case for your specific requirements.

In summary, a protective case with foam is an investment in the safety and longevity of your equipment. Whether you are in the military, medical, photography, or any other industry, these cases provide the ultimate protection solution, giving you peace of mind that your items are well-protected.

Frequently Asked Questions About Protective Cases with Foam

What are the main benefits of using foam in protective cases?

Foam provides superior shock absorption, a customizable fit, effective vibration dampening, and lightweight yet durable protection. Different foam types cater to various needs, ensuring that your items are well-protected during transport and storage.

Which industries benefit most from protective cases with foam?

Industries such as electronics, military and defense, medical, aerospace, and photography and videography benefit the most from protective cases with foam. These cases ensure sensitive and valuable items remain safe from damage.

How do I choose the right type of foam for my protective case?

Consider the dimensions of your items, the type of foam (e.g., polyurethane, polyethylene), the durability of both the case and foam, the ability to customize the foam inserts, portability, environmental resistance, and additional security features.

What are some top brands offering protective cases with foam?

Prominent brands include Pelican, SKB, Gator, Nanuk, Seahorse, and Underwater Kinetics. These brands are known for their durable, high-quality cases that offer various sizes and configurations with customizable foam inserts.

How can I maintain the foam in my protective case?

Regularly inspect the foam for wear, clean it with a vacuum, avoid overloading the case, store it in a cool, dry place, replace worn-out foam, and use desiccants to prevent moisture buildup. Proper maintenance ensures long-lasting protection.