Thermoforming

Thermoforming

Thermoforming in Packaging

Thermoforming is a popular method in the packaging industry. It involves heating a plastic sheet until it becomes pliable. Then, the sheet is shaped into a specific form using a mold.

How Thermoforming Works

The process starts by heating a plastic sheet. Once heated, the sheet is stretched over a mold. Vacuum or pressure is applied to ensure the sheet takes the shape of the mold. After cooling, the plastic retains its new shape.

Types of Thermoforming

There are two main types of thermoforming: vacuum forming and pressure forming. Vacuum forming uses a vacuum to pull the plastic sheet against the mold. Pressure forming uses additional air pressure to push the sheet into the mold. Both methods create detailed and precise packaging.

Advantages of Thermoforming

Thermoforming offers several benefits. It is cost-effective and allows for quick production. The process is also versatile, making it suitable for various packaging needs. Additionally, thermoforming can produce lightweight and durable packaging.

Applications in Packaging

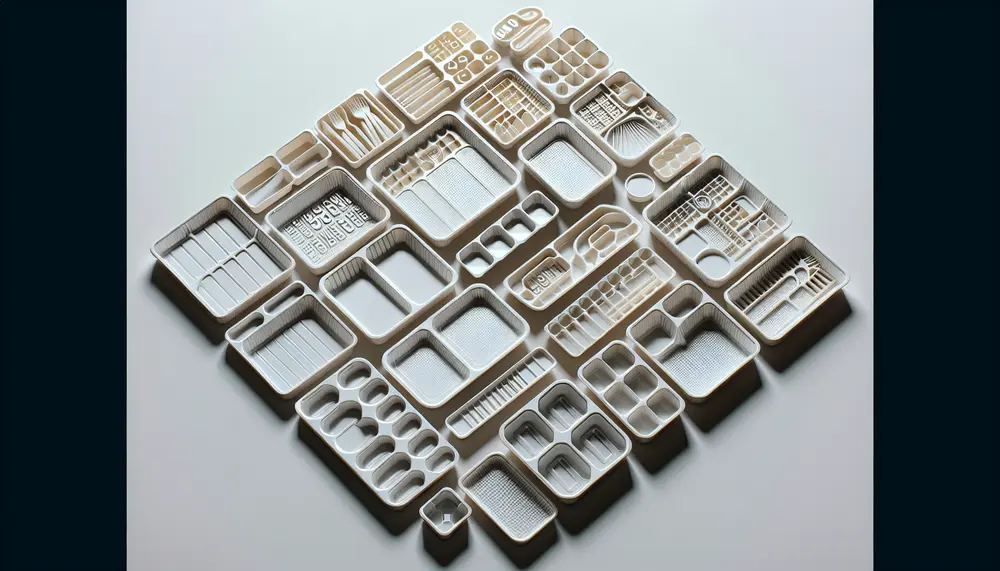

Thermoforming is used in many packaging applications. Common examples include food containers, blister packs, and clamshell packaging. These products protect items and enhance their presentation.

Materials Used in Thermoforming

Various plastics are used in thermoforming. Popular choices include PET, PVC, and polystyrene. Each material has unique properties, making it suitable for different packaging needs.

Conclusion

Thermoforming is a key process in the packaging industry. It offers flexibility, efficiency, and cost savings. Understanding thermoforming can help you appreciate the complexity behind everyday packaging.

Blog Posts with the term: Thermoforming

Cornstarch is a biodegradable, eco-friendly alternative to traditional packaging materials, offering similar functionalities with less environmental impact. It's used in various industries for products like containers and bags, reduces reliance on fossil fuels, and supports climate change efforts by emitting...

Plastic trays are essential in various industries for their customizable size, shape, and material, offering versatility from warehouse organization to sterilized medical packaging. They come in different designs like compartmentalized or vented ones and have evolved with eco-friendly options to...

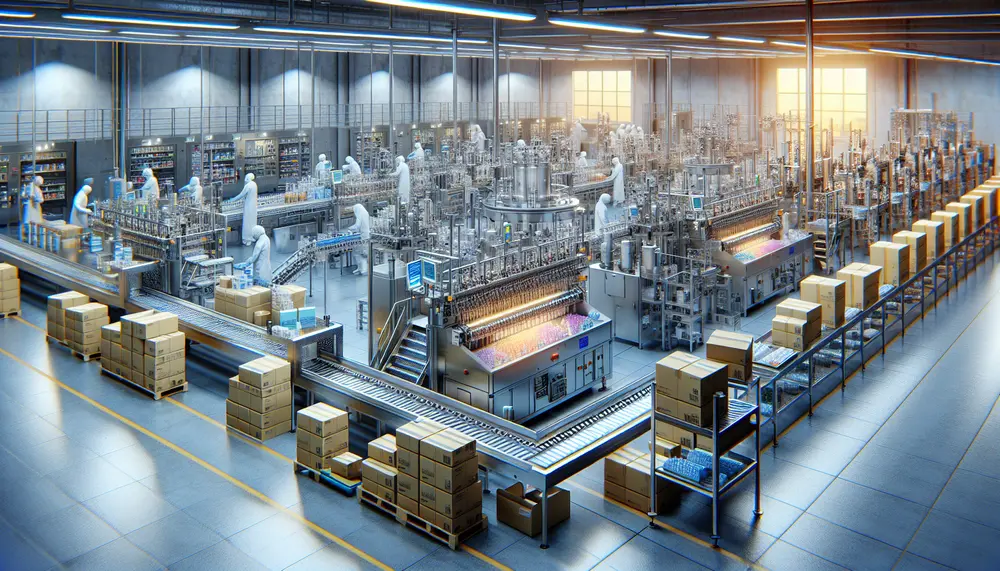

The pharmaceutical packaging value chain is essential for ensuring medications are safely delivered from manufacturers to patients, involving steps like design and development, material selection, manufacturing processes, quality control, distribution logistics, regulatory compliance, and sustainability. Each component plays a crucial...

Universal protective packaging offers a versatile, cost-efficient solution for safeguarding products across various industries during transit and storage. Its adaptable design ensures enhanced product safety, improved customer satisfaction, and eco-friendly options while simplifying the packaging process....