Thermoformed tray

Thermoformed tray

Thermoformed Tray

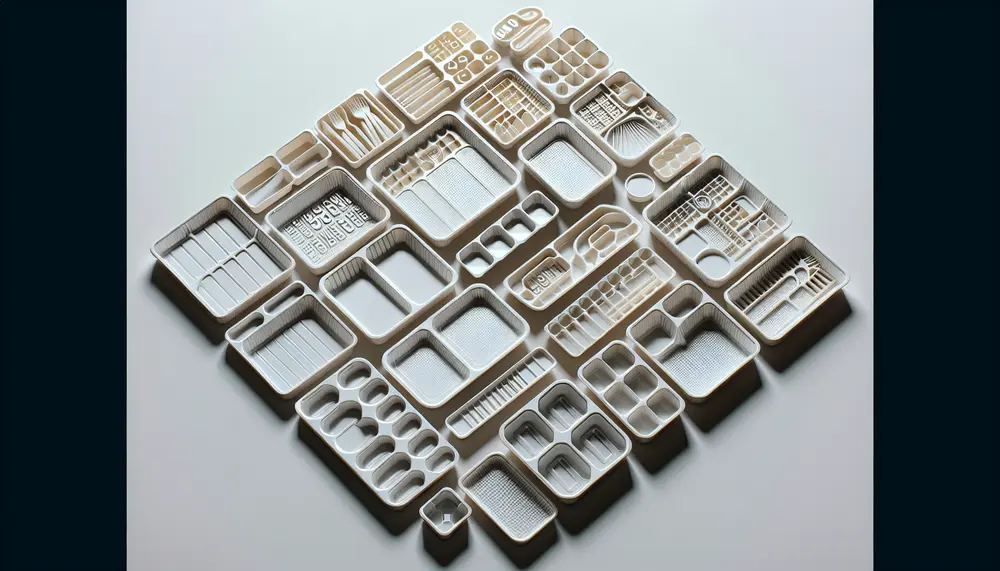

A thermoformed tray is a type of packaging made by heating a plastic sheet until it becomes pliable. The heated sheet is then shaped into a specific form using a mold. This process is called thermoforming.

How Thermoformed Trays Are Made

First, a plastic sheet is heated. Once it reaches the right temperature, it is placed over a mold. Air pressure or vacuum is used to shape the plastic into the mold. After cooling, the tray is trimmed to its final shape.

Uses of Thermoformed Trays

Thermoformed trays are common in various industries. They are used for packaging food, electronics, and medical devices. These trays protect products and keep them organized.

Benefits of Thermoformed Trays

One major benefit is customization. Thermoformed trays can be designed to fit specific products. They are also lightweight, which reduces shipping costs. Additionally, they are often recyclable, making them an eco-friendly option.

Conclusion

In summary, a thermoformed tray is a versatile and practical packaging solution. It offers protection, organization, and customization for various products. Understanding how they are made and their benefits can help you choose the right packaging for your needs.