Tamper-evident seal

Tamper-evident seal

What is a Tamper-evident Seal?

A tamper-evident seal is a packaging feature that shows if someone has opened or tampered with a product. It helps ensure the product's safety and integrity.

Why Use a Tamper-evident Seal?

Using a tamper-evident seal protects consumers. It gives them confidence that the product is safe and untouched. This is crucial for food, medicine, and other sensitive items.

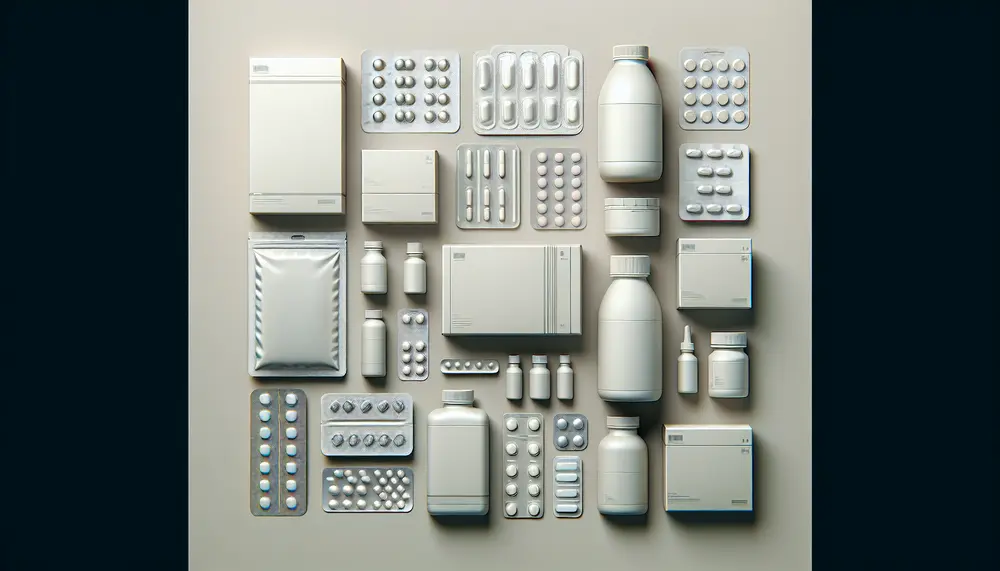

Types of Tamper-evident Seals

There are various types of tamper-evident seals. Common examples include shrink bands, breakable caps, and adhesive labels. Each type serves the same purpose but works in different ways.

How Do Tamper-evident Seals Work?

A tamper-evident seal works by showing clear signs of tampering. For instance, a broken seal or a missing band indicates that the product may have been opened. This visual cue alerts consumers to potential issues.

Benefits of Tamper-evident Seals

The main benefit of a tamper-evident seal is consumer safety. It also helps build trust in the brand. Companies that use these seals show they care about product integrity and customer well-being.

Examples in Everyday Life

You can find tamper-evident seals on many products. Examples include bottled drinks, medicine containers, and food packages. These seals are a common sight in supermarkets and pharmacies.

Blog Posts with the term: Tamper-evident seal

Ensuring compliance in pharmaceutical packaging is essential for product integrity, patient safety, and regulatory approval. This article outlines key guidelines from major regulatory bodies like the FDA, EMA, ICH, WHO, and USP that govern material selection, design standards, labeling requirements,...

Pharmaceutical packaging for export requires strict adherence to international regulations set by global regulatory bodies like WHO, ICH, EMA, FDA, and PMDA to ensure safety and quality. Key regulations include Good Manufacturing Practice (GMP), ISO standards, serialization systems, labeling requirements,...

Protective packaging involves materials and methods to safeguard products from damage during shipping, handling, and storage. It is crucial for maintaining product integrity, reducing costs associated with returns and replacements, ensuring compliance with regulations, protecting against environmental factors, enhancing customer...

Pharmaceutical packaging and design are essential for ensuring medication safety, efficacy, and patient compliance. Effective packaging involves understanding regulatory requirements, material science, and user needs while providing protection, information, identification, convenience, and adherence to treatment plans; it must also comply...

Pharmaceutical packaging is essential for maintaining medication safety, stability, and compliance with regulatory standards; it protects from external elements and contamination while ensuring patient adherence through clear labeling and user-friendly designs. When choosing a pharmaceutical packaging manufacturer, consider their certifications,...

Pharmaceutical packaging is essential for protecting medications from contamination and degradation, providing critical information through labeling, ensuring regulatory compliance, and enhancing user experience with features like child-resistant caps. While it offers benefits such as safe transportation and storage, challenges include...

Ziplock packaging bags offer a versatile and sustainable solution for storage, organization, and transportation needs across various industries. They are reusable, come in different sizes with additional features, and advancements include recycled material options to reduce environmental impact. Recycled ziplock packaging...

The FDA ensures drug packaging safety and efficacy through stringent guidelines on material quality, labeling accuracy, child-resistant features, tamper-evident seals, and environmental considerations. Compliance with these standards protects public health by preventing contamination and ensuring clear information is provided to...

Tablet packaging materials are essential for protecting medication from contamination and damage, with properties tailored to the pharmaceutical product's needs. Secure tablet packaging is vital in maintaining drug potency, ensuring patient safety through tamper evidence, preventing misuse or accidental ingestion,...

LDPE film is a flexible, transparent thermoplastic used extensively in packaging for its chemical resistance and moisture barrier properties, which are crucial across industries like food, pharmaceuticals, and agriculture. It stands out due to its recyclability and balance of protection,...

Pharmaceutical packaging is essential for ensuring medication safety, efficacy, and providing critical information. Innovations like tamper-evident seals, child-resistant mechanisms, smart technology integration, and sustainable materials are enhancing patient safety, compliance, and environmental responsibility in the industry....

Pharmaceutical packaging is vital for ensuring medication safety and integrity, involving primary components that protect against environmental factors and secondary packaging that aids in branding and protection during transit. Technological advancements like automated inspection systems enhance quality control, while compliance...

Understanding packaging box materials is crucial for product presentation, protection, and environmental impact. Material choice affects cost, durability, and sustainability; factors like strength and recyclability must be considered. Paper-based boxes are versatile and range from cardboard to corrugated options with varying...

Understanding the basics of packaging is essential for product protection, presentation, and meeting legal standards. It involves considering physical characteristics, user experience, and regulatory compliance to create effective solutions. Different types of packaging materials serve various functions and have distinct environmental...

Understanding and selecting the right pharmaceutical packaging materials is essential for maintaining drug safety, efficacy, and integrity. These materials must protect against environmental factors like moisture and light while ensuring compatibility with the drugs they contain; innovations in this field...