Tamper-evident

Tamper-evident

What is Tamper-evident Packaging?

Tamper-evident packaging is a type of packaging designed to show if it has been opened or altered. This feature helps protect the product inside from tampering and ensures its safety for consumers.

Why is Tamper-evident Packaging Important?

Tamper-evident packaging is crucial for several reasons. It helps maintain the integrity of the product, ensuring that it has not been contaminated. It also builds trust with consumers, as they can see that the product is safe and secure.

Common Types of Tamper-evident Packaging

There are various types of tamper-evident packaging. Some common examples include:

- Sealed caps on bottles that make a popping sound when opened.

- Shrink bands around the neck of a container.

- Breakable seals that must be broken to open the package.

- Blister packs that show clear signs if tampered with.

Benefits of Tamper-evident Packaging

Tamper-evident packaging offers many benefits. It helps prevent product tampering, reduces the risk of contamination, and increases consumer confidence. This type of packaging is especially important for food, pharmaceuticals, and other sensitive products.

Conclusion

In summary, tamper-evident packaging is essential for product safety and consumer trust. By using tamper-evident features, companies can ensure their products remain secure and intact until they reach the end user.

Blog Posts with the term: Tamper-evident

Yogurt packaging is essential for maintaining freshness, quality, and safety; it requires an effective barrier against oxygen and light, strength during transportation, regulatory compliance for food contact, and advanced sealing technology. Innovations in the market include smart features like freshness...

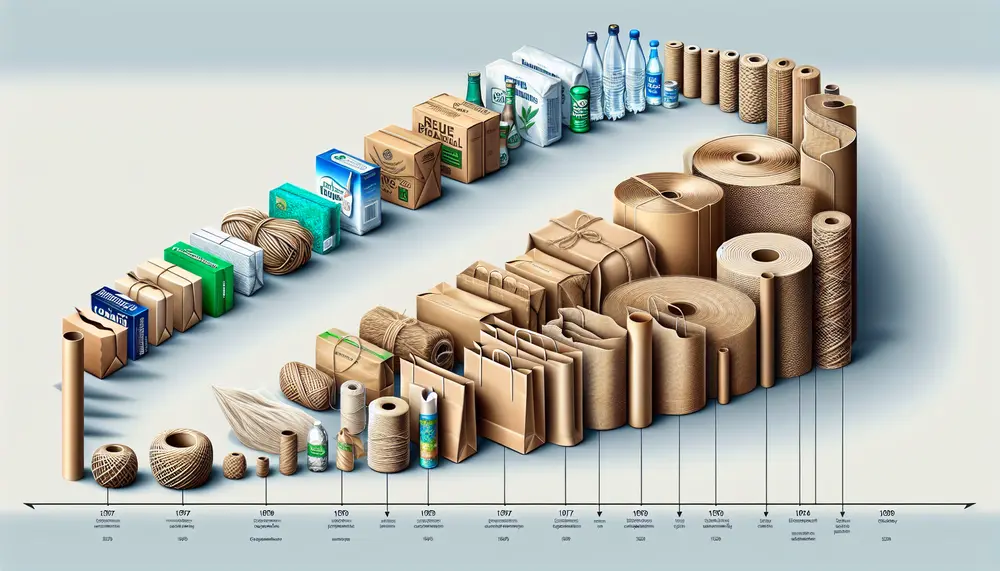

Packaging is a complex, engineered process for product protection, presentation, and preservation with functions including containment and information. It has evolved to incorporate user experience, environmental considerations, and technological advancements. Historically packaging materials have advanced from natural resources to modern lightweight...

Ensuring compliance in pharmaceutical packaging is essential for product integrity, patient safety, and regulatory approval. This article outlines key guidelines from major regulatory bodies like the FDA, EMA, ICH, WHO, and USP that govern material selection, design standards, labeling requirements,...

OPP bags, known for their strength and clarity, are essential in packaging for protection, presentation, and preservation of products. They offer advantages like durability, resealability, cost-effectiveness but have drawbacks such as being non-biodegradable; various types exist to suit different applications. Different...

Selecting the right packaging for desserts is crucial as it affects freshness, safety, customer experience, and environmental impact. The three main materials—plastic, paper (cardboard), and aluminum—each have their benefits and drawbacks concerning durability, visibility, branding potential, sustainability concerns, and protection...

The packaging and technology revolution is transforming product protection, preservation, and presentation through intelligent systems, AR/VR experiences, digital printing for customization, with a focus on data security in smart packaging solutions. This intersection of fields offers innovation opportunities across industries. Technology's...

Pharmaceutical packaging for export requires strict adherence to international regulations set by global regulatory bodies like WHO, ICH, EMA, FDA, and PMDA to ensure safety and quality. Key regulations include Good Manufacturing Practice (GMP), ISO standards, serialization systems, labeling requirements,...

Packaging R&D is essential for innovation in the industry, focusing on functionality, efficiency, sustainability and improving user experience while minimizing environmental impact. Innovation drives packaging solutions forward with smart technologies and eco-friendly materials to meet market needs and reduce environmental...

Packaging design has evolved from mere protection to a complex brand storytelling and consumer engagement tool, incorporating aesthetics, functionality, sustainability, and technology. It enhances user experience through convenience, visual appeal, emotional connection, and by reflecting the product's quality....

Protective packaging involves materials and methods to safeguard products from damage during shipping, handling, and storage. It is crucial for maintaining product integrity, reducing costs associated with returns and replacements, ensuring compliance with regulations, protecting against environmental factors, enhancing customer...

The packaging industry is governed by a complex legal framework aimed at ensuring safety, health, and environmental protection. Key regulations include material restrictions like RoHS and REACH, compostability standards such as BPI certification, and heavy metal limitations under CONEG legislation. Regulatory...

Pharmaceutical packaging and design are essential for ensuring medication safety, efficacy, and patient compliance. Effective packaging involves understanding regulatory requirements, material science, and user needs while providing protection, information, identification, convenience, and adherence to treatment plans; it must also comply...

Ziplock packaging bags offer a versatile and sustainable solution for storage, organization, and transportation needs across various industries. They are reusable, come in different sizes with additional features, and advancements include recycled material options to reduce environmental impact. Recycled ziplock packaging...

Pharmaceutical packaging is essential for maintaining medication safety, stability, and compliance with regulatory standards; it protects from external elements and contamination while ensuring patient adherence through clear labeling and user-friendly designs. When choosing a pharmaceutical packaging manufacturer, consider their certifications,...

Pharmaceutical packaging is essential for protecting medications from contamination and degradation, providing critical information through labeling, ensuring regulatory compliance, and enhancing user experience with features like child-resistant caps. While it offers benefits such as safe transportation and storage, challenges include...