Rigid packaging

Rigid packaging

Rigid Packaging

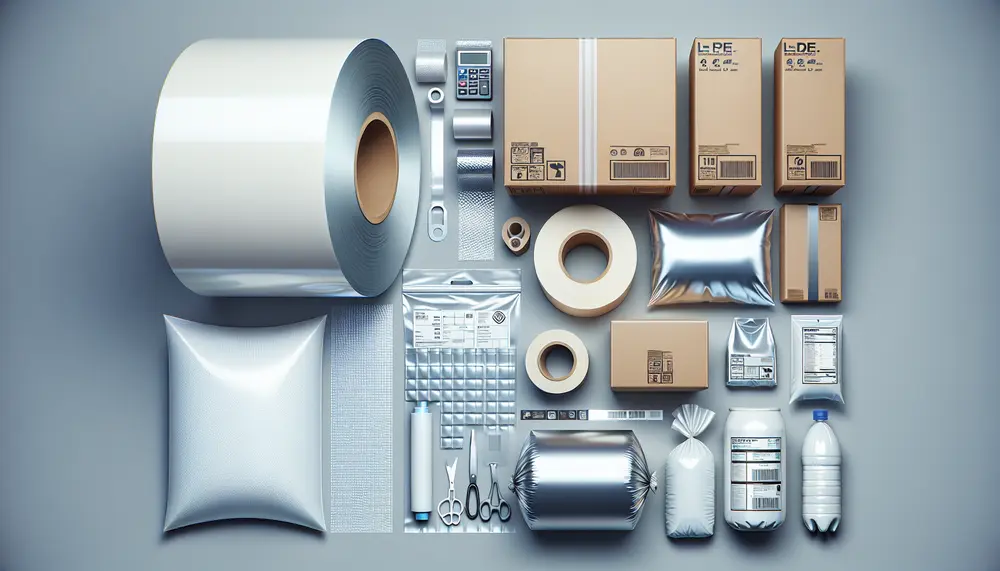

Rigid packaging refers to packaging that maintains its shape and structure when filled or during use. This type of packaging is made from sturdy materials like plastic, glass, metal, or cardboard. Unlike flexible packaging, rigid packaging does not bend or flex easily.

Materials Used in Rigid Packaging

Common materials for rigid packaging include:

- Plastic: Used for bottles, containers, and jars.

- Glass: Ideal for jars, bottles, and vials.

- Metal: Often used for cans and tins.

- Cardboard: Commonly used for boxes and cartons.

Advantages of Rigid Packaging

Rigid packaging offers several benefits:

- Protection: Provides excellent protection for products during transport and storage.

- Durability: Resistant to damage and can withstand rough handling.

- Presentation: Enhances product display and can be designed attractively.

Applications of Rigid Packaging

Rigid packaging is used in various industries, including:

- Food and Beverage: For packaging items like canned goods, bottled drinks, and jars of sauces.

- Pharmaceuticals: Used for pill bottles, syringes, and medical vials.

- Cosmetics: Ideal for creams, lotions, and perfumes.

- Electronics: Protects gadgets and components during shipping.

Conclusion

Rigid packaging is essential for many products that require strong, durable, and protective packaging. Its ability to maintain shape and provide security makes it a popular choice across various industries.

Blog Posts with the term: Rigid packaging

Understanding sustainable packaging is vital for businesses to minimize environmental impact and meet consumer demands, focusing on eco-friendly materials and practices. Key concepts include life cycle assessment, recyclability, and the circular economy, which guide companies in selecting suitable materials while...

Flexible and soft packaging materials are cost-effective, protective solutions that bend to fit contents; they combine substrates like plastics for barrier protection and branding. The industry is shifting towards these lightweight, customizable options due to consumer convenience, sustainability benefits, and...

OPP bags, known for their strength and clarity, are essential in packaging for protection, presentation, and preservation of products. They offer advantages like durability, resealability, cost-effectiveness but have drawbacks such as being non-biodegradable; various types exist to suit different applications. Different...

The resurgence of paper carry bags in retail is driven by their eco-friendliness and consumer demand for sustainability, with advancements in production enhancing durability and design. Despite being less durable than plastic, especially when wet, they offer a stylish, customizable...

LDPE film is a flexible, transparent thermoplastic used extensively in packaging for its chemical resistance and moisture barrier properties, which are crucial across industries like food, pharmaceuticals, and agriculture. It stands out due to its recyclability and balance of protection,...

Pharmaceutical packaging design companies play a crucial role in ensuring medication safety, compliance with regulatory standards, and enhancing user experience while incorporating sustainable practices. Key industry players like Amcor, Gerresheimer, West Pharmaceutical Services, SGD Pharma, and Becton Dickinson drive innovation...

Packaging materials are essential for product protection, quality preservation, and shelf life extension across industries; they must balance protection with presentation and logistics efficiency. The food industry uses diverse packaging types like plastics, biodegradables, glass, metals, paper-based solutions to meet...

Rigid packaging materials like glass, metal, and certain plastics are chosen for their durability and protective qualities against external pressure. They offer advantages such as high strength and barrier properties but also have disadvantages including higher costs and sustainability concerns. Different...

Protective packaging manufacturers design and produce solutions to safeguard products from damage, contamination, and environmental factors during transportation and storage. They work with various industries to create customized packaging using materials like foam, bubble wrap, corrugated cardboard, plastic films, barrier...