Resin

Resin

Resin in Packaging

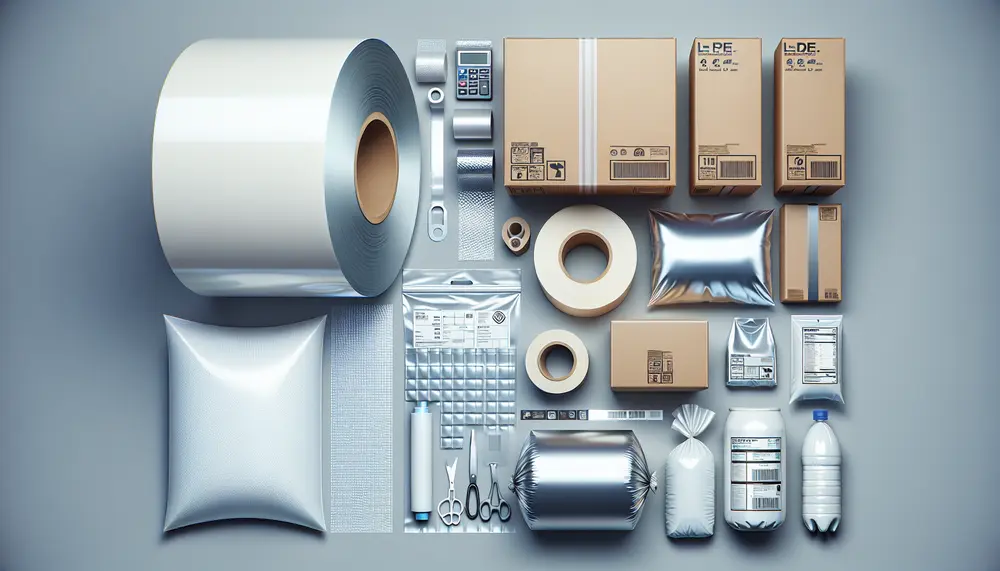

Resin is a key material in the packaging industry. It is a type of synthetic or natural substance that can be molded into different shapes. Resins are used to create a variety of packaging products, from bottles to films.

Types of Resin

There are several types of resin used in packaging. The most common ones include polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET). Each type has unique properties that make it suitable for different packaging needs.

Benefits of Using Resin

Resin offers many benefits in packaging. It is lightweight, which reduces shipping costs. It is also durable, providing good protection for products. Additionally, resin can be transparent, allowing consumers to see the product inside.

Environmental Impact

Resin packaging has both positive and negative environmental impacts. On the positive side, it can be recycled, reducing waste. However, not all resins are biodegradable, which can lead to long-term environmental issues if not properly managed.

Conclusion

Understanding the role of resin in packaging helps in making informed choices. It is a versatile material that offers many benefits but also comes with environmental responsibilities. By choosing the right type of resin and managing its disposal, we can enjoy its advantages while minimizing its drawbacks.

Blog Posts with the term: Resin

HDPE packaging is valued for its durability, lightweight nature, and resistance to environmental factors. It's versatile in shape and size customization, cost-effective during transport due to its light weight, and environmentally friendly as it's 100% recyclable. High-density polyethylene (HDPE) is a...

High-Density Polyethylene (HDPE) is a durable, versatile thermoplastic with a high strength-to-density ratio used in packaging, construction, and various other applications due to its resistance to impact and chemicals. HDPE's production involves polymerization of ethylene gas using different methods that...

Food contact materials (FCMs) must be safe as they can transfer substances into food, with safety ensured through rigorous assessments and migration tests. The FDA regulates FCMs in the U.S., requiring scientific evidence for approval or recognition under GRAS standards....

HDPE bags are known for their strength, flexibility, and eco-friendliness due to their robust molecular structure; they resist impacts, chemicals, moisture, and temperature variations while being recyclable. Their durability allows multiple uses and secure transportation of goods with less environmental...

Sustainable packaging minimizes environmental impact through eco-friendly, efficient, and recyclable materials. It addresses pollution concerns, meets consumer demands for green practices, and provides competitive advantages to companies. The evolution of eco-friendly packaging has progressed from reducing material use to introducing biodegradable...

Pharmaceutical packaging bottles are designed to protect, preserve, and deliver medications effectively while ensuring safety, regulatory compliance, and user convenience. Key considerations include material compatibility, barrier properties, child-resistant features, sterility assurance, sustainability efforts like bio-based plastics or glass alternatives for...

LDPE film is a flexible, transparent thermoplastic used extensively in packaging for its chemical resistance and moisture barrier properties, which are crucial across industries like food, pharmaceuticals, and agriculture. It stands out due to its recyclability and balance of protection,...

Sustainable pharmaceutical packaging is under urgent scrutiny due to high CO₂ emissions, regulatory pressure, and the need for safe, recyclable solutions. Cutting-edge recycling technologies—like advanced mechanical sorting, chemical depolymerization, carbon capture polymers, bio-based materials, and digital watermarking—are driving a shift...

The 2023 packaging and waste regulation emphasizes sustainability, with new directives pushing for circular economy models and improved design for recyclability. Businesses must adapt to these changes, which include Extended Producer Responsibility (EPR), incentivizing eco-friendly packaging innovation. EU packaging waste regulations...

Traditional packaging materials, derived from nature and reflecting past ingenuity and environmental consciousness, symbolize a time of resourcefulness and minimal waste. These biodegradable materials offer sustainability benefits such as lower energy production processes, carbon sequestration, and support for biodiversity. A variety...

Composite materials are transforming the packaging industry by providing improved performance and durability, with their unique composition allowing for tailored properties to meet specific needs. Innovations in technology like smart composites, nanocomposites, and 3D printing are further advancing these materials'...

Plastic packaging for cleaning agents is designed to be chemically resistant and secure, with specific plastics chosen based on their interaction with the product's chemicals. Child-safe features like CR closures are essential for preventing accidental access by children. Eco-friendly plastic options...

Stretch film, a highly elastic plastic wrap used for securing items during transport or storage, comes in various types and has evolved with technology to offer improved durability and efficiency. Innovations include nano-hybrid films, intelligent tracking features, automated application systems,...

Packaging recycling is essential for environmental sustainability, conserving resources and reducing landfill waste. It faces challenges like cost and contamination but offers benefits such as reduced emissions and job creation. The impact of packaging waste includes ocean pollution, greenhouse gas emissions...

When choosing a food grade packaging factory, prioritize end-to-end traceability, rigorous material testing, real-time monitoring, strong hygiene culture, flexibility, and transparent documentation. True compliance means proactive risk management and clear communication—if these are lacking or vague, keep searching for a...