Packaging Industry

Packaging Industry

Packaging Industry

The Packaging Industry involves the design, production, and distribution of packaging materials. These materials include boxes, bottles, bags, and other containers used to protect and transport products.

Key Components

The Packaging Industry has several key components. These include raw material suppliers, packaging manufacturers, and end-users. Raw material suppliers provide the basic materials like paper, plastic, and glass. Packaging manufacturers then create the packaging products. End-users are the companies that use these products to package their goods.

Importance of the Packaging Industry

The Packaging Industry plays a crucial role in modern commerce. It ensures that products reach consumers in good condition. Packaging also helps in branding and marketing. A well-designed package can attract customers and boost sales.

Trends in the Packaging Industry

The Packaging Industry is constantly evolving. Sustainable packaging is a major trend. Companies are looking for eco-friendly materials to reduce their environmental impact. Another trend is smart packaging, which uses technology to improve the user experience.

Challenges in the Packaging Industry

The Packaging Industry faces several challenges. These include rising material costs and strict environmental regulations. Companies must innovate to stay competitive. They need to find new ways to reduce costs and meet regulatory requirements.

Blog Posts with the term: Packaging Industry

Leaf-based packaging materials are ancient practices re-emerging for modern sustainability, utilizing plant leaves as biodegradable and renewable solutions with minimal environmental impact. They reduce carbon emissions compared to plastic production, decompose rapidly without toxic residues, and align with circular economy...

Cornstarch is a biodegradable, eco-friendly alternative to traditional packaging materials, offering similar functionalities with less environmental impact. It's used in various industries for products like containers and bags, reduces reliance on fossil fuels, and supports climate change efforts by emitting...

Packaging regulations are crucial for businesses involved in the manufacture, distribution or sale of packaged goods. They protect consumers and support fair competition by governing every aspect of packaging from design to label information. Compliance with these rules is essential...

The Kenyan packaging market is valued at around $585 million, driven by sectors like agriculture and manufacturing which contribute to the GDP; growth in consumer demand has led to innovations such as small affordable packages and a shift towards sustainable...

LDPE bags are versatile and durable packaging solutions made from Low-Density Polyethylene, suitable for a wide range of applications including food packaging, medical supplies, retail merchandise, industrial parts, and agricultural products. They offer benefits such as cost efficiency, protective qualities...

HDPE packaging is valued for its durability, lightweight nature, and resistance to environmental factors. It's versatile in shape and size customization, cost-effective during transport due to its light weight, and environmentally friendly as it's 100% recyclable. High-density polyethylene (HDPE) is a...

Remote packaging jobs offer flexible, home-based opportunities driven by e-commerce growth, requiring minimal qualifications and catering to diverse skill levels. These roles provide cost savings, autonomy, and steady demand but may involve challenges like repetitive tasks or managing distractions at...

The article discusses the significance of yogurt packaging materials in preserving quality, extending shelf life, and marketing. It highlights various types of packaging like glass, plastic, composites, eco-friendly alternatives, and metal containers with their respective properties. Packaging choices for yogurt impact...

This article discusses the evolution and variety of milk packaging materials, highlighting their role in preserving milk's freshness, taste, and nutrition. It covers historical advancements from glass bottles to modern sustainable options, examining each material's benefits and drawbacks for consumers...

Yogurt packaging is essential for maintaining freshness, quality, and safety; it requires an effective barrier against oxygen and light, strength during transportation, regulatory compliance for food contact, and advanced sealing technology. Innovations in the market include smart features like freshness...

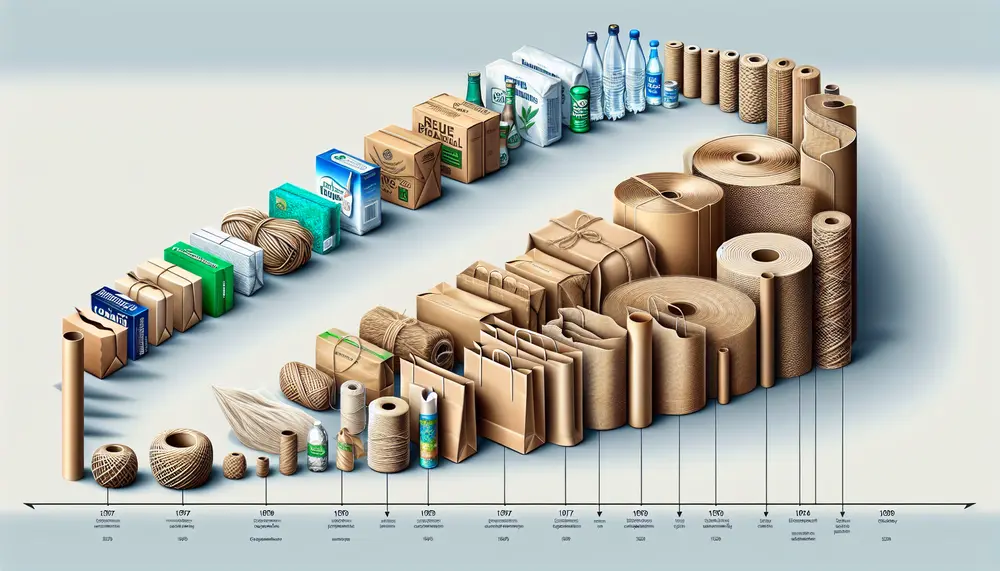

Packaging is a complex, engineered process for product protection, presentation, and preservation with functions including containment and information. It has evolved to incorporate user experience, environmental considerations, and technological advancements. Historically packaging materials have advanced from natural resources to modern lightweight...

A packaging operator oversees the final stages of manufacturing, ensuring products are correctly packed and labeled for shipping. Their responsibilities include managing machinery, preparing materials, monitoring operations, performing maintenance tasks, keeping production records and adhering to safety protocols while maintaining...

Packaging in marketing is a multifaceted tool that influences brand perception and market success, serving not only to protect products but also as a silent salesman through design elements that convey brand values. It enhances visibility, appeal, protection, communication of...

Glass packaging is valued for its durability, inertness, and transparency, ideal for storing various products while being 100% recyclable. Different types of glass like borosilicate and soda-lime are used in packaging due to their unique properties such as thermal resistance...

Flexible and soft packaging materials are cost-effective, protective solutions that bend to fit contents; they combine substrates like plastics for barrier protection and branding. The industry is shifting towards these lightweight, customizable options due to consumer convenience, sustainability benefits, and...