Monomaterial

Monomaterial

Monomaterial in Packaging

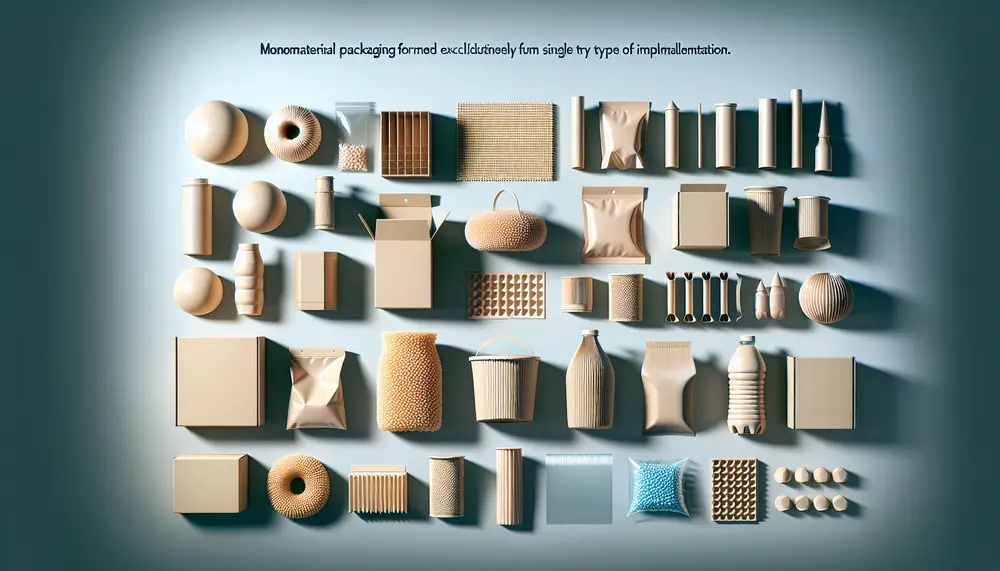

Monomaterial refers to packaging made from a single type of material. This concept is gaining popularity in the packaging industry due to its environmental benefits.

Why Monomaterial Matters

Using monomaterial in packaging makes recycling easier. When a package is made from only one material, it can be processed without separating different components. This reduces waste and supports a circular economy.

Examples of Monomaterial Packaging

Common examples include plastic bottles made entirely of PET or cardboard boxes without plastic coatings. These types of packaging are simpler to recycle and often more cost-effective.

Benefits of Monomaterial

Monomaterial packaging offers several advantages. It simplifies the recycling process, reduces contamination, and can lower production costs. Additionally, it aligns with sustainability goals by minimizing waste.

Challenges of Monomaterial

Despite its benefits, monomaterial packaging can face challenges. For instance, it may not always provide the same level of protection as multi-material packaging. Finding the right balance between functionality and recyclability is key.

Conclusion

Monomaterial is a crucial concept in sustainable packaging. By using a single material, it promotes easier recycling and supports environmental goals. As the industry evolves, monomaterial solutions will likely become more prevalent.

Blog Posts with the term: Monomaterial

Europe leads in sustainable packaging, integrating eco-friendly materials and methods to reduce environmental impact. This shift is driven by consumer awareness, strict regulations, and a collaborative effort among stakeholders to set global examples for balancing ecology with business growth. The rise...

Pharmaceutical packaging bottles are designed to protect, preserve, and deliver medications effectively while ensuring safety, regulatory compliance, and user convenience. Key considerations include material compatibility, barrier properties, child-resistant features, sterility assurance, sustainability efforts like bio-based plastics or glass alternatives for...

Hygiene packaging is crucial for protecting public health by preventing contamination of products like sanitizers and wipes, while also needing to be visually appealing and informative. Effective hygiene packaging features barrier protection, seal integrity, resealable closures, tamper-evidence, ergonomic design, and...

Plastic barriers are essential in packaging for product protection and preservation, involving polymers with specific properties to prevent permeation of gases, moisture, and chemicals. They come in various forms like films or coatings and must be carefully selected based on...

Packaging and labelling play a crucial role in marketing by shaping consumer perception, building trust, differentiating brands, ensuring compliance, and enhancing user experience. Effective packaging and labelling drive purchase decisions through clear information, emotional connection, unique design elements, transparency, and...

Sustainable pharmaceutical packaging is under urgent scrutiny due to high CO₂ emissions, regulatory pressure, and the need for safe, recyclable solutions. Cutting-edge recycling technologies—like advanced mechanical sorting, chemical depolymerization, carbon capture polymers, bio-based materials, and digital watermarking—are driving a shift...

Monomaterial packaging, made from a single material for improved recyclability and production efficiency, faces challenges in maintaining product protection while research continues to develop suitable materials. The shift towards monomaterials aids the environment by reducing carbon footprints and waste, streamlining...