Label

Label

Label

A label is a piece of paper, plastic, or other material attached to a product's packaging. It provides important information about the product.

Purpose of a Label

The main purpose of a label is to inform the consumer. It includes details like the product name, ingredients, and expiration date. Labels also often show branding elements like logos and slogans.

Types of Labels

There are various types of labels used in packaging. Some common types include:

- Brand Labels: Display the brand name and logo.

- Informative Labels: Provide product details like ingredients and usage instructions.

- Grade Labels: Indicate the quality or grade of the product.

Importance of Labels in Packaging

Labels play a crucial role in packaging. They help consumers make informed choices. They also ensure compliance with legal requirements. For example, food products must have labels showing nutritional information.

Designing Effective Labels

Designing an effective label involves several factors. The design should be clear and easy to read. It should also be visually appealing to attract consumers. Using high-quality materials ensures the label remains intact during handling and storage.

Conclusion

In summary, a label is a vital part of packaging. It provides essential information and helps in branding. Understanding the different types and purposes of labels can enhance the effectiveness of your packaging.

Blog Posts with the term: Label

Cornstarch is a biodegradable, eco-friendly alternative to traditional packaging materials, offering similar functionalities with less environmental impact. It's used in various industries for products like containers and bags, reduces reliance on fossil fuels, and supports climate change efforts by emitting...

Packaging levels refer to the layers of packaging used from production to consumer, including primary (direct product contact), secondary (grouping and branding), and tertiary (bulk handling). Each level serves distinct purposes in protection, marketing, transportation, and regulatory compliance....

Packaging regulations are crucial for businesses involved in the manufacture, distribution or sale of packaged goods. They protect consumers and support fair competition by governing every aspect of packaging from design to label information. Compliance with these rules is essential...

Packaging design is a process of creating exterior product protection and communication tool that encapsulate a brand's identity, conveys essential information about the product, and influences consumer purchasing decisions. Designers should prioritize clarity and simplicity, emphasize originality, ensure functionality, design...

LDPE bags are versatile and durable packaging solutions made from Low-Density Polyethylene, suitable for a wide range of applications including food packaging, medical supplies, retail merchandise, industrial parts, and agricultural products. They offer benefits such as cost efficiency, protective qualities...

Remote packaging jobs offer flexible, home-based opportunities driven by e-commerce growth, requiring minimal qualifications and catering to diverse skill levels. These roles provide cost savings, autonomy, and steady demand but may involve challenges like repetitive tasks or managing distractions at...

HDPE packaging is valued for its durability, lightweight nature, and resistance to environmental factors. It's versatile in shape and size customization, cost-effective during transport due to its light weight, and environmentally friendly as it's 100% recyclable. High-density polyethylene (HDPE) is a...

The article discusses the significance of yogurt packaging materials in preserving quality, extending shelf life, and marketing. It highlights various types of packaging like glass, plastic, composites, eco-friendly alternatives, and metal containers with their respective properties. Packaging choices for yogurt impact...

This article discusses the evolution and variety of milk packaging materials, highlighting their role in preserving milk's freshness, taste, and nutrition. It covers historical advancements from glass bottles to modern sustainable options, examining each material's benefits and drawbacks for consumers...

Yogurt packaging is essential for maintaining freshness, quality, and safety; it requires an effective barrier against oxygen and light, strength during transportation, regulatory compliance for food contact, and advanced sealing technology. Innovations in the market include smart features like freshness...

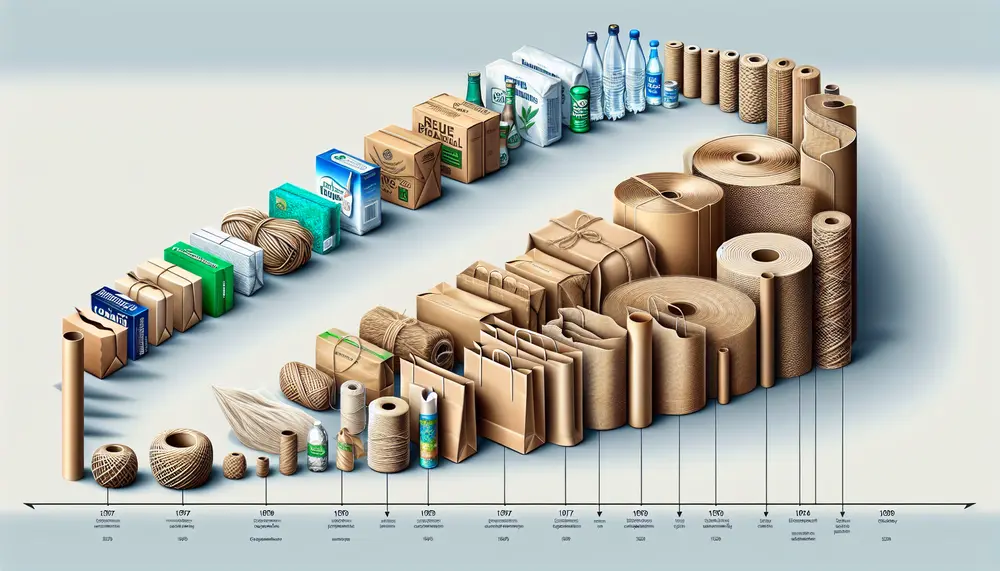

Packaging is a complex, engineered process for product protection, presentation, and preservation with functions including containment and information. It has evolved to incorporate user experience, environmental considerations, and technological advancements. Historically packaging materials have advanced from natural resources to modern lightweight...

A packaging operator oversees the final stages of manufacturing, ensuring products are correctly packed and labeled for shipping. Their responsibilities include managing machinery, preparing materials, monitoring operations, performing maintenance tasks, keeping production records and adhering to safety protocols while maintaining...

Packaging in marketing is a multifaceted tool that influences brand perception and market success, serving not only to protect products but also as a silent salesman through design elements that convey brand values. It enhances visibility, appeal, protection, communication of...

This guide offers step-by-step instructions for creative gift wrapping techniques like zig-zag folds, pocket methods, and origami accents to elevate your presents. It also provides festive packaging ideas using layered textures, custom tags, personalized elements, unique color palettes, and reusable...