Heat seal

Heat seal

Heat Seal

A heat seal is a method used in packaging to join two materials together using heat and pressure. This technique is common in creating airtight and watertight seals for various products.

How Does Heat Sealing Work?

During the heat sealing process, two surfaces are pressed together and heated. The heat melts the surfaces, allowing them to bond. Once cooled, the materials form a strong seal.

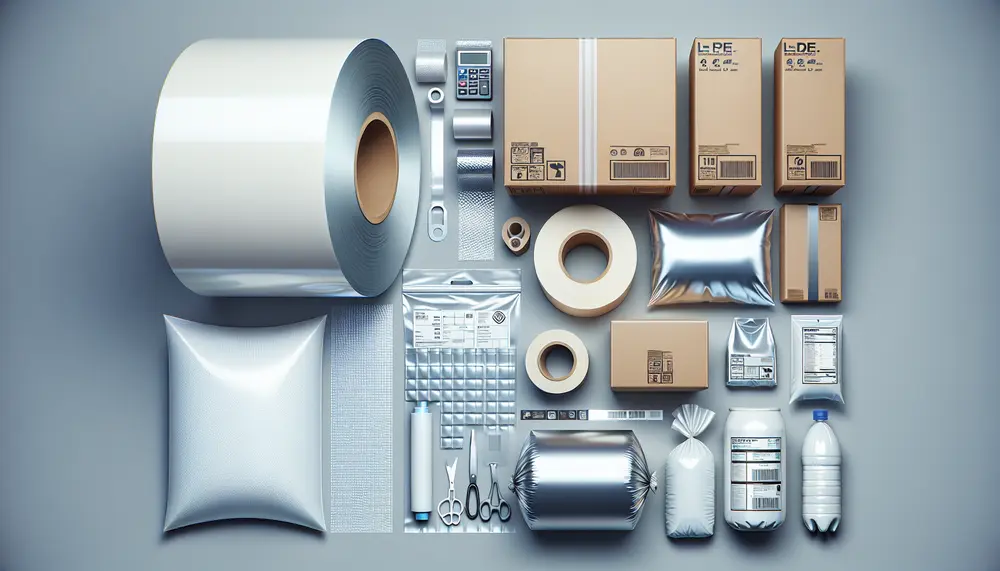

Materials Used in Heat Sealing

Common materials for heat sealing include plastics like polyethylene and polypropylene. These materials melt and bond well under heat and pressure.

Applications of Heat Sealing

Heat seals are used in various industries. Food packaging often uses heat seals to keep products fresh. Medical packaging also relies on heat seals to maintain sterility.

Advantages of Heat Sealing

The main benefits of heat sealing include creating secure, airtight, and watertight seals. This method is efficient and cost-effective for mass production.

Conclusion

In summary, a heat seal is a vital technique in packaging. It ensures products remain safe and secure, making it a preferred choice in many industries.

Blog Posts with the term: Heat seal

Yogurt packaging is essential for maintaining freshness, quality, and safety; it requires an effective barrier against oxygen and light, strength during transportation, regulatory compliance for food contact, and advanced sealing technology. Innovations in the market include smart features like freshness...

OPP bags, known for their strength and clarity, are essential in packaging for protection, presentation, and preservation of products. They offer advantages like durability, resealability, cost-effectiveness but have drawbacks such as being non-biodegradable; various types exist to suit different applications. Different...

Flexible and soft packaging materials are cost-effective, protective solutions that bend to fit contents; they combine substrates like plastics for barrier protection and branding. The industry is shifting towards these lightweight, customizable options due to consumer convenience, sustainability benefits, and...

Vacuum packaging extends food shelf life by removing air to prevent microbial growth, oxidation, and moisture changes. It's versatile for various products and involves specialized machinery that creates a low-oxygen environment to protect against spoilage....

EO sterilization is a vital low-temperature method for medical devices, requiring packaging that allows gas penetration and maintains sterility. Packaging materials like PE, PP, polystyrene, nylon, PET, and multilayer laminates are compatible with EO but must be designed to ensure...

LDPE film is a flexible, transparent thermoplastic used extensively in packaging for its chemical resistance and moisture barrier properties, which are crucial across industries like food, pharmaceuticals, and agriculture. It stands out due to its recyclability and balance of protection,...

Roll bags, made from HDPE for strength and moisture resistance, are versatile and convenient for storage and packaging in various settings due to their easy dispensing design. They're portable, clear for labeling, resilient against leaks, fitting into roll bag dispensers...

Packaging nylon bags are valued for their strength, durability, and versatility in protecting products from damage and contamination across various industries. However, they pose environmental concerns due to non-biodegradability and potential release of harmful chemicals if improperly disposed of....

Vacuum sealers extend food shelf life, prevent freezer burn, maintain quality and flavor, aid in portion control and meal planning, reduce waste, and save storage space. However, they come with initial costs for the machine and bags which can be...

Protective packaging for medical devices is essential to ensure their safety, integrity, and sterility during transportation and storage. It involves selecting appropriate materials that can withstand sterilization processes while providing physical protection and maintaining regulatory compliance....

Packaging rolls are essential for product protection, efficiency, and cost reduction across various industries. They offer customizability to meet specific needs such as material strength and transparency. Different types of packaging rolls cater to unique industry requirements with materials like biodegradable...

Packaging automation refers to the use of automated machinery and robotics for packaging products, increasing efficiency, reducing costs, and minimizing human error. The evolution of this technology has been driven by rising labor costs, increased demand for goods and services,...

Protective packaging in the USA is essential for safeguarding products during storage and transportation, with companies offering advanced materials and custom solutions to protect against damage, moisture, and environmental factors. Key features include durability, moisture resistance, temperature control, customizability, ease...

Protective Packaging Corporation, established in 1987 and based in Carrollton, TX, offers innovative packaging solutions to protect products from damage, moisture, and corrosion. Their services include on-site packaging, barrier bags, corrosion prevention consulting, and custom packaging options tailored to meet...

Maintaining mushroom freshness during packaging is complex, requiring careful control of respiration, moisture, microbial risks, and environmental gases. Success depends on precise harvest timing, gentle handling, optimal humidity and temperature conditions, strict hygiene practices, and selecting tailored packaging materials to...