Extrusion

Extrusion

Extrusion in Packaging

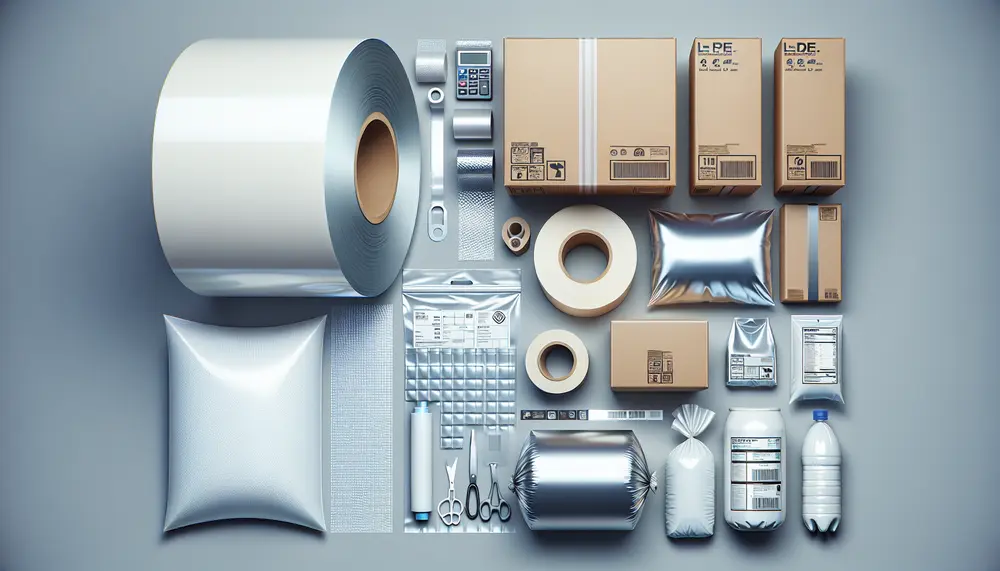

Extrusion is a key process in the packaging industry. It involves pushing material through a shaped opening to create long, continuous shapes. These shapes can be used to make various packaging products.

How Extrusion Works

The extrusion process starts with raw material, often plastic or metal. This material is heated until it becomes soft. Then, it is forced through a die, which gives it a specific shape. As the material cools, it hardens into the desired form.

Types of Extrusion

There are several types of extrusion used in packaging. Blown film extrusion creates thin plastic films for bags and wraps. Sheet extrusion produces thicker sheets for items like trays and lids. Profile extrusion makes custom shapes for products like tubes and pipes.

Benefits of Extrusion

Extrusion offers many benefits for packaging. It allows for the creation of complex shapes with high precision. The process is also efficient, producing large quantities quickly. Additionally, extrusion can use recycled materials, making it an eco-friendly option.

Applications in Packaging

Extrusion is used in many packaging applications. It produces films for food packaging, sheets for containers, and profiles for protective packaging. The versatility of extrusion makes it a valuable process in the packaging industry.

Blog Posts with the term: Extrusion

LDPE bags are versatile and durable packaging solutions made from Low-Density Polyethylene, suitable for a wide range of applications including food packaging, medical supplies, retail merchandise, industrial parts, and agricultural products. They offer benefits such as cost efficiency, protective qualities...

HDPE packaging is valued for its durability, lightweight nature, and resistance to environmental factors. It's versatile in shape and size customization, cost-effective during transport due to its light weight, and environmentally friendly as it's 100% recyclable. High-density polyethylene (HDPE) is a...

HDPE bags are known for their strength, flexibility, and eco-friendliness due to their robust molecular structure; they resist impacts, chemicals, moisture, and temperature variations while being recyclable. Their durability allows multiple uses and secure transportation of goods with less environmental...

The article discusses the significant role of packaging giants in driving innovation and efficiency within the industry, focusing on their strategic importance, market dominance across various materials, and efforts to meet changing demands with sustainable solutions. It highlights how these...

LDPE film is a flexible, transparent thermoplastic used extensively in packaging for its chemical resistance and moisture barrier properties, which are crucial across industries like food, pharmaceuticals, and agriculture. It stands out due to its recyclability and balance of protection,...

RPET packaging, made from recycled Polyethylene Terephthalate (PET), is a sustainable alternative to virgin plastic that reduces waste and greenhouse gas emissions. Europe leads in its use, driven by consumer demand for eco-friendly products and legislation promoting recycling and the...

Packaging rolls are essential for product protection, efficiency, and cost reduction across various industries. They offer customizability to meet specific needs such as material strength and transparency. Different types of packaging rolls cater to unique industry requirements with materials like biodegradable...

Plastic packaging for cleaning agents is designed to be chemically resistant and secure, with specific plastics chosen based on their interaction with the product's chemicals. Child-safe features like CR closures are essential for preventing accidental access by children. Eco-friendly plastic options...

Edible packaging is an eco-friendly innovation designed to be eaten with the product, reducing waste and using sustainable resources. It offers benefits for both manufacturers and consumers, aligning with demands for environmentally friendly products amid climate change challenges. The edible packaging...