Customization

Customization

Customization in Packaging

Customization in packaging refers to the process of tailoring packaging solutions to meet specific needs or preferences. This can involve altering the design, size, shape, or materials used in the packaging to better suit the product or brand.

Why Customization Matters

Customization is crucial because it helps brands stand out in a crowded market. Unique packaging can attract more customers and enhance the overall brand experience. For example, a company might use eco-friendly materials to appeal to environmentally conscious consumers.

Types of Customization

There are several types of customization in packaging:

- Design Customization: Adjusting colors, logos, and graphics to align with brand identity.

- Structural Customization: Modifying the shape or size of the packaging to fit the product better.

- Material Customization: Choosing specific materials like recycled paper or biodegradable plastics.

Benefits of Customization

Customization offers numerous benefits. It can improve product protection, enhance customer satisfaction, and even reduce waste. For instance, using the right-sized packaging minimizes the need for extra filler materials.

Challenges of Customization

While customization has many advantages, it also presents challenges. It can be more costly and time-consuming than using standard packaging. However, the long-term benefits often outweigh these initial drawbacks.

Conclusion

In summary, customization in packaging is a powerful tool for brands. It allows for unique, tailored solutions that can significantly impact customer perception and satisfaction. By investing in customized packaging, companies can better meet their customers' needs and stand out in the marketplace.

Blog Posts with the term: Customization

Cornstarch is a biodegradable, eco-friendly alternative to traditional packaging materials, offering similar functionalities with less environmental impact. It's used in various industries for products like containers and bags, reduces reliance on fossil fuels, and supports climate change efforts by emitting...

Unique packaging designs enhance gift boxes by creating memorable unboxing experiences and reflecting the giver's care. Personal touches, eco-friendly materials, and innovative design elements can elevate both personal gifts and brand identity. Creative packaging for gifts makes a strong first impression,...

The Kenyan packaging market is valued at around $585 million, driven by sectors like agriculture and manufacturing which contribute to the GDP; growth in consumer demand has led to innovations such as small affordable packages and a shift towards sustainable...

LDPE bags are versatile and durable packaging solutions made from Low-Density Polyethylene, suitable for a wide range of applications including food packaging, medical supplies, retail merchandise, industrial parts, and agricultural products. They offer benefits such as cost efficiency, protective qualities...

The article discusses the significance of yogurt packaging materials in preserving quality, extending shelf life, and marketing. It highlights various types of packaging like glass, plastic, composites, eco-friendly alternatives, and metal containers with their respective properties. Packaging choices for yogurt impact...

Yogurt packaging is essential for maintaining freshness, quality, and safety; it requires an effective barrier against oxygen and light, strength during transportation, regulatory compliance for food contact, and advanced sealing technology. Innovations in the market include smart features like freshness...

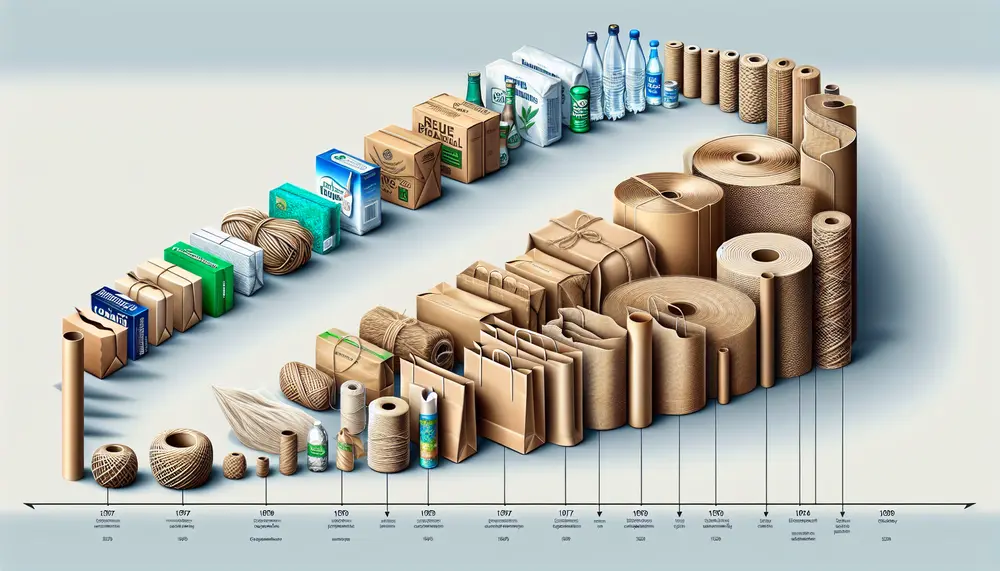

Packaging is a complex, engineered process for product protection, presentation, and preservation with functions including containment and information. It has evolved to incorporate user experience, environmental considerations, and technological advancements. Historically packaging materials have advanced from natural resources to modern lightweight...

Packaging in marketing is a multifaceted tool that influences brand perception and market success, serving not only to protect products but also as a silent salesman through design elements that convey brand values. It enhances visibility, appeal, protection, communication of...

Glass packaging is valued for its durability, inertness, and transparency, ideal for storing various products while being 100% recyclable. Different types of glass like borosilicate and soda-lime are used in packaging due to their unique properties such as thermal resistance...

Understanding sustainable packaging is vital for businesses to minimize environmental impact and meet consumer demands, focusing on eco-friendly materials and practices. Key concepts include life cycle assessment, recyclability, and the circular economy, which guide companies in selecting suitable materials while...

Flexible and soft packaging materials are cost-effective, protective solutions that bend to fit contents; they combine substrates like plastics for barrier protection and branding. The industry is shifting towards these lightweight, customizable options due to consumer convenience, sustainability benefits, and...

OPP bags, known for their strength and clarity, are essential in packaging for protection, presentation, and preservation of products. They offer advantages like durability, resealability, cost-effectiveness but have drawbacks such as being non-biodegradable; various types exist to suit different applications. Different...

The packaging industry's value chain encompasses material procurement, design and development, manufacturing, distribution, marketing, sales, and after-sales service. Challenges such as environmental regulations, consumer demands for sustainability, cost volatility, technological advances, globalization issues, and supply chain complexity necessitate strategic planning...

Packaging nets are crucial for protecting and transporting various products, offering benefits like airflow for perishables, visibility without opening the package, lightweight nature to reduce shipping costs, and environmental friendliness. They come in different types—extruded, knitted, woven, elastic—with specific characteristics...

Effective electronic packaging is essential for protecting devices during transport and storage, impacting customer satisfaction and brand reputation. A guide to materials like plastic cushioning, thermoformed plastics, shielding bags, foams, and desiccants helps in selecting the right protection based on...