Blister packaging

Blister packaging

Blister Packaging

Blister packaging is a type of packaging that uses a pre-formed plastic cavity or pocket. This cavity is usually made from a formable web, such as plastic or aluminum. It is often used to protect and display small consumer goods, foods, and pharmaceuticals.

Components of Blister Packaging

Blister packaging consists of two main parts: the blister and the backing. The blister is the clear plastic part that holds the product. The backing is usually made of paperboard, plastic, or aluminum foil. Together, they create a sealed package that keeps the product safe and visible.

Types of Blister Packaging

There are several types of blister packaging. The most common types are face-seal blister, full-face seal blister, and trapped blister. Each type has its own unique features and uses. For example, face-seal blisters are often used for lightweight items, while trapped blisters provide extra security for heavier products.

Advantages of Blister Packaging

Blister packaging offers many benefits. It provides excellent protection against moisture, contamination, and tampering. It also allows consumers to see the product before purchasing. This type of packaging is cost-effective and easy to produce, making it a popular choice for many industries.

Common Uses of Blister Packaging

Blister packaging is widely used in various industries. In the pharmaceutical industry, it is used for packaging tablets and capsules. In the consumer goods sector, it is used for packaging items like batteries, toys, and hardware. The food industry also uses blister packaging for products like cheese and snacks.

Blog Posts with the term: Blister packaging

Pharmaceutical packaging and design are essential for ensuring medication safety, efficacy, and patient compliance. Effective packaging involves understanding regulatory requirements, material science, and user needs while providing protection, information, identification, convenience, and adherence to treatment plans; it must also comply...

NAICS codes are essential for categorizing industries, particularly in pharmaceutical packaging, with code 325412 covering manufacturing and 561910 focusing on packaging services; understanding these distinctions aids compliance, market analysis, and strategic planning. Key industry players like Johnson & Johnson, Pfizer,...

The article discusses the importance of selecting high-quality pharmaceutical packaging equipment manufacturers and profiles several leading companies in this sector. It highlights ACIC Pharmaceuticals, Körber AG, IDEX Corporation, Bosch Group, and Marchesini Group S.p.A., emphasizing their innovative solutions, global reach,...

Tablet packaging materials are essential for protecting medication from contamination and damage, with properties tailored to the pharmaceutical product's needs. Secure tablet packaging is vital in maintaining drug potency, ensuring patient safety through tamper evidence, preventing misuse or accidental ingestion,...

Advanced packaging machines enhance efficiency and productivity in modern production lines by automating tasks, ensuring precision, and enabling cost savings. They are crucial for businesses to stay competitive and meet industry standards. High-efficiency packaging machines feature user-friendly interfaces, modular designs, precise...

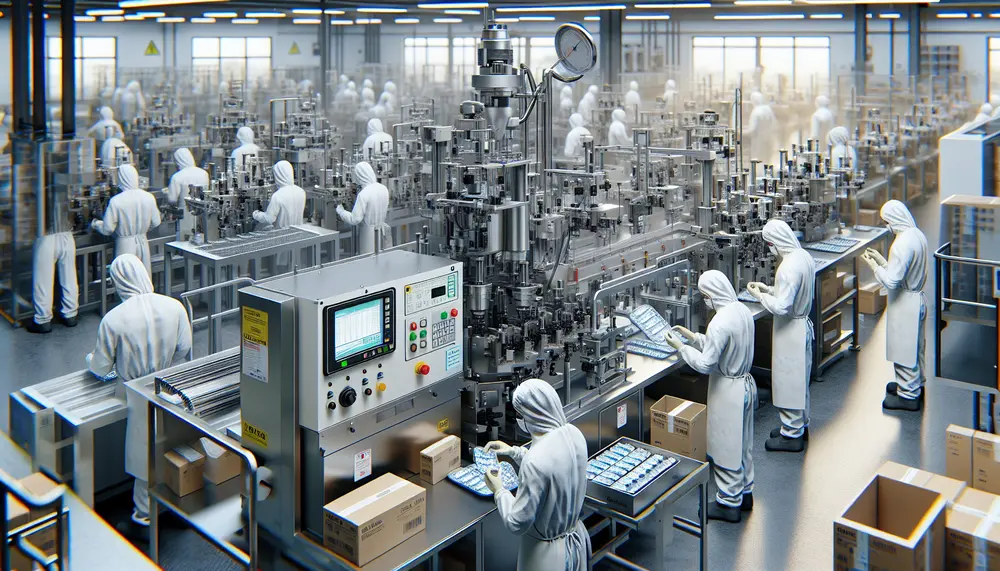

Pharmaceutical packaging equipment is essential for maintaining the safety, integrity, and efficacy of medications by adhering to strict regulatory standards. This includes a variety of machines like blister pack machines, bottle filling machines, and labeling systems that ensure protective containment...

Pharmaceutical packaging in South Africa is a complex blend of science and art focused on ensuring safe delivery of medicines, governed by strict regulations like GMP and overseen by SAHPRA to maintain high safety standards....

The pharmaceutical packaging industry in India is crucial for global healthcare, focusing on safe drug distribution and innovative solutions like tamper-evident features while adapting to market needs with sustainable practices. The sector is experiencing robust growth, driven by innovations, health...

Pharmaceutical packaging waste significantly contributes to global environmental issues, with plastics being a major component that ends up in landfills and oceans, releasing toxins and increasing carbon emissions. Efforts to address this include exploring sustainable materials like bio-based plastics and...

Red alerts in pharmacy packaging are critical safety tools that use high-visibility design elements to prevent medication errors, benefiting both healthcare professionals and patients. By highlighting essential information like dosage limits or warnings against misuse, they enhance clarity, reduce risks...

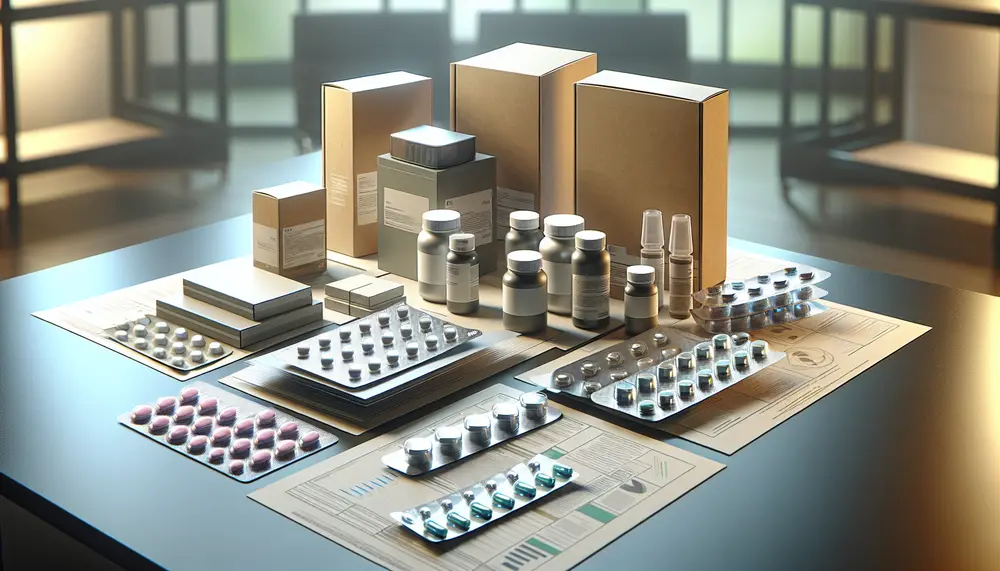

Pharmaceutical packaging solutions are essential for ensuring the safety, efficacy, and stability of medications by protecting them from environmental factors, contamination, and physical damage. The industry is evolving with advanced materials like blister packs and smart technologies such as RFID...

The role of a pharmaceutical packaging operator is vital in ensuring the safety and efficacy of medications by handling the final stage of drug production, which includes operating specialized machinery to package various forms such as tablets and liquids while...

The pharmaceutical industry is evolving with innovations in packaging that enhance patient safety, improve drug efficacy, and meet regulatory requirements. Key advancements include smart blister packs for tracking medication adherence, high-barrier materials for protection against environmental factors, tamper-evident bottle features,...

Pharmaceutical packaging is essential for protecting medications, ensuring safety and efficacy through materials like glass and plastics, and adhering to strict regulatory standards. Innovations in the field include biodegradable polymers and smart packaging technologies that enhance drug protection and environmental...

Pharmaceutical packaging is essential for maintaining the safety, efficacy, and quality of medications, involving various forms like blisters, bottles, and syringes to protect against damage, moisture, contamination, and tampering. The design of this packaging must consider material suitability, regulatory compliance...