Blister pack

Blister pack

Blister Pack

A blister pack is a type of packaging that consists of a pre-formed plastic cavity or pocket, usually sealed with a cardboard backing or aluminum foil. This packaging is commonly used for small consumer goods, pharmaceuticals, and food items.

Components of a Blister Pack

A typical blister pack has two main parts: the blister and the backing. The blister is the clear plastic part that holds the product. The backing is the material that seals the blister, keeping the product secure and protected.

Types of Blister Packs

There are several types of blister packs, including:

- Face-seal blister packs: The blister is sealed to the front of a cardboard backing.

- Full-face seal blister packs: The blister covers the entire front of the backing.

- Trapped blister packs: The blister is trapped between two layers of cardboard.

Advantages of Blister Packs

Blister packs offer many benefits. They provide excellent protection for products, keeping them safe from moisture, contamination, and damage. They also allow consumers to see the product before purchasing, which can increase sales.

Common Uses of Blister Packs

Blister packs are widely used in various industries. In the pharmaceutical industry, they are used to package pills and capsules. In the consumer goods sector, they are used for items like batteries, toys, and hardware. In the food industry, they are used for products like chewing gum and candies.

Conclusion

Understanding what a blister pack is and its uses can help you make informed decisions about packaging. Whether you are a consumer or a business, knowing the benefits and types of blister packs can be valuable.

Blog Posts with the term: Blister pack

Packaging levels refer to the layers of packaging used from production to consumer, including primary (direct product contact), secondary (grouping and branding), and tertiary (bulk handling). Each level serves distinct purposes in protection, marketing, transportation, and regulatory compliance....

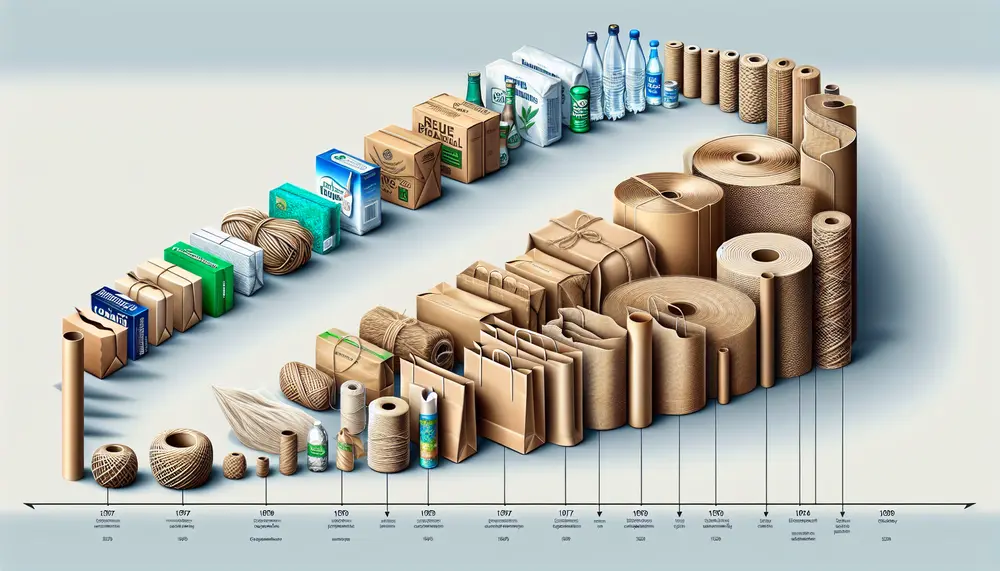

Packaging is a complex, engineered process for product protection, presentation, and preservation with functions including containment and information. It has evolved to incorporate user experience, environmental considerations, and technological advancements. Historically packaging materials have advanced from natural resources to modern lightweight...

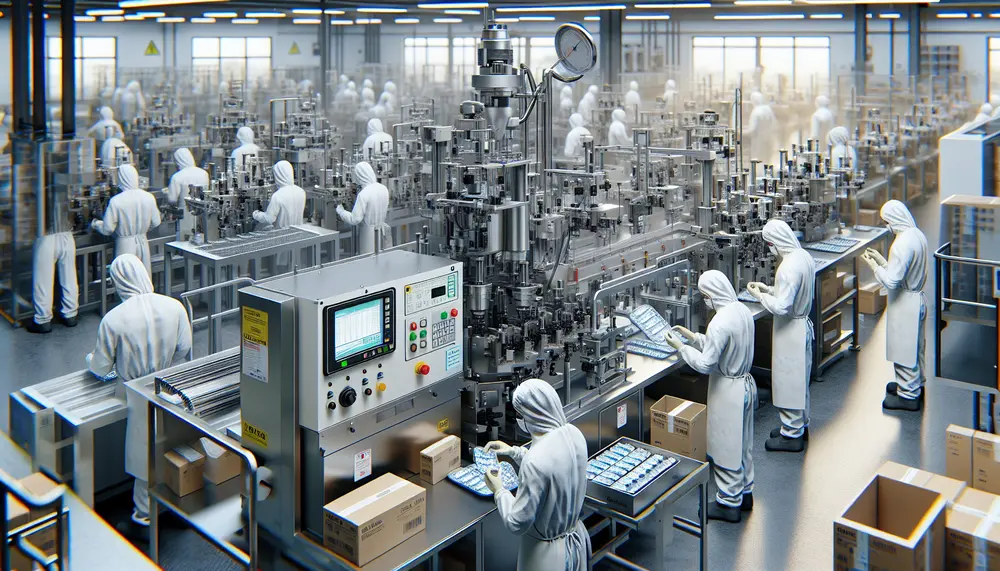

Ensuring compliance in pharmaceutical packaging is essential for product integrity, patient safety, and regulatory approval. This article outlines key guidelines from major regulatory bodies like the FDA, EMA, ICH, WHO, and USP that govern material selection, design standards, labeling requirements,...

Packaging materials range from traditional paper and glass to modern bioplastics, each with unique properties affecting product safety, cost-effectiveness, and environmental impact. Selecting the right packaging is crucial for brand identity, customer satisfaction, and sustainability; factors like protection needs, branding...

Perforation in packaging design is a critical element that enhances product breathability, user access, and maintains integrity during transport. It requires careful consideration of material properties and precise techniques to ensure functionality without compromising quality. The role of perforation extends to...

Effective electronic packaging is essential for protecting devices during transport and storage, impacting customer satisfaction and brand reputation. A guide to materials like plastic cushioning, thermoformed plastics, shielding bags, foams, and desiccants helps in selecting the right protection based on...

Pharmaceutical packaging defects can compromise product integrity, posing health risks and financial losses; common defects include uneven sealing surfaces, raised seams, excess bottom flash, uneven sides, foreign material presence, and incorrect material specifications. Identifying causes such as material quality issues,...

Protective packaging involves materials and methods to safeguard products from damage during shipping, handling, and storage. It is crucial for maintaining product integrity, reducing costs associated with returns and replacements, ensuring compliance with regulations, protecting against environmental factors, enhancing customer...

The pharmaceutical packaging HS code is essential for global trade, ensuring regulatory compliance, accurate tariff calculations, and efficient customs clearance. Understanding and correctly using the HS code helps businesses avoid delays, fines, and ensures smooth international operations by accurately classifying...

Pharmaceutical packaging design combines functionality with creativity, using visualization and stunning imagery to build trust, convey clarity, and reinforce brand identity. While it enhances consumer engagement and eco-friendliness, challenges include potential complexity, higher costs, and balancing aesthetics with practicality....

Pharmaceutical packaging and design are essential for ensuring medication safety, efficacy, and patient compliance. Effective packaging involves understanding regulatory requirements, material science, and user needs while providing protection, information, identification, convenience, and adherence to treatment plans; it must also comply...

Effective packaging layout is essential for visual communication, guiding consumer attention and influencing purchase decisions through a hierarchy of design elements. It's not just about aesthetics but also functionality, including barcode placement and legal requirements. Packaging layout significantly affects consumer perception...

NAICS codes are essential for categorizing industries, particularly in pharmaceutical packaging, with code 325412 covering manufacturing and 561910 focusing on packaging services; understanding these distinctions aids compliance, market analysis, and strategic planning. Key industry players like Johnson & Johnson, Pfizer,...

The pharmaceutical packaging industry is rapidly evolving with trends focusing on sustainability, smart technologies, and personalized solutions to meet consumer demands and regulatory requirements. While these innovations offer benefits like reduced environmental impact and enhanced patient engagement, they also present...

Pharmaceutical packaging is a science focused on ensuring medicines are safe, effective, and user-friendly through primary, secondary, and tertiary types using various materials while adhering to regulatory compliance. Innovations in smart technology and sustainable practices continue to evolve the field...