Barrier film

Barrier film

Barrier Film

A barrier film is a type of packaging material designed to protect products from external elements. It acts as a shield against moisture, oxygen, light, and other environmental factors that can affect the quality and shelf life of the product.

How Does Barrier Film Work?

Barrier films work by creating a physical barrier that prevents unwanted substances from penetrating the packaging. This is achieved through the use of multiple layers of different materials, each with specific properties. For example, one layer might block oxygen, while another layer prevents moisture from getting in.

Types of Barrier Films

There are several types of barrier films, each designed for specific applications. Common types include:

- Metalized Films: These films have a thin layer of metal, usually aluminum, which provides excellent barrier properties.

- Plastic Films: These are made from polymers like polyethylene or polypropylene and offer good moisture and oxygen barriers.

- Coated Films: These films have a special coating that enhances their barrier properties.

Applications of Barrier Films

Barrier films are used in various industries to package products that need protection from external elements. Common applications include:

- Food Packaging: Keeps food fresh by preventing spoilage from moisture and oxygen.

- Pharmaceutical Packaging: Protects medicines from light, moisture, and contamination.

- Electronics Packaging: Shields electronic components from moisture and static electricity.

Benefits of Using Barrier Films

Using barrier films in packaging offers several benefits:

- Extended Shelf Life: Products stay fresh and usable for longer periods.

- Enhanced Protection: Products are safeguarded against environmental factors.

- Versatility: Suitable for a wide range of products and industries.

Blog Posts with the term: Barrier film

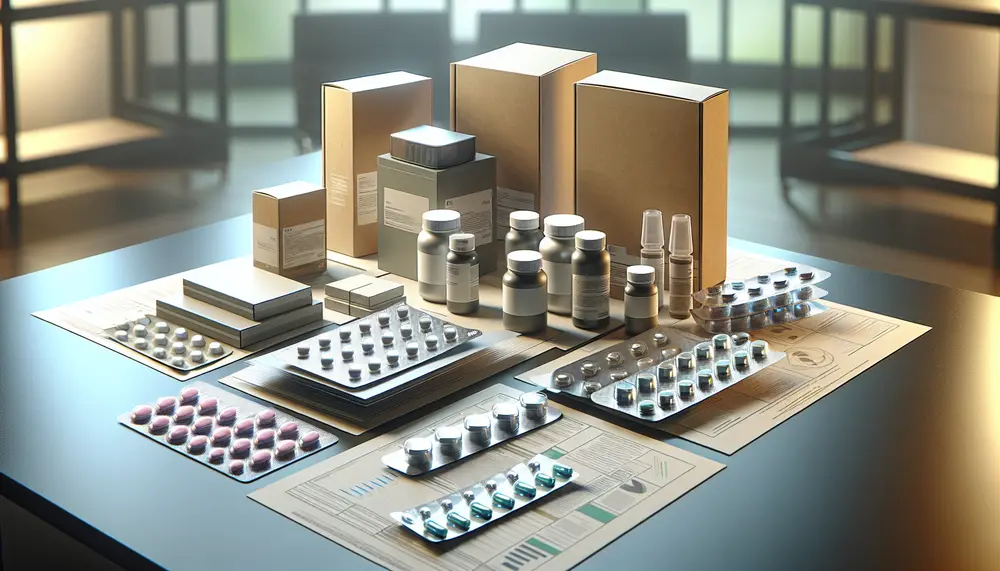

Pharmaceutical packaging is essential for maintaining medication safety, stability, and compliance with regulatory standards; it protects from external elements and contamination while ensuring patient adherence through clear labeling and user-friendly designs. When choosing a pharmaceutical packaging manufacturer, consider their certifications,...

Flexible packaging in the pharmaceutical industry enhances protection, usability, and sustainability by offering versatile solutions for various medications while reducing costs and environmental impact. Its applications range from oral medications to injectables, providing tailored options that improve product safety and...

The article explores the evolution, current trends and future of packaging technology. It highlights how packaging has evolved from simple containers to complex systems incorporating design elements, consumer psychology, sustainability concerns and logistical strategies; with recent innovations focusing on biodegradable...

Pharmaceutical packaging work involves designing, producing, and evaluating containers for medications to ensure safety and efficiency in delivery while maintaining product integrity through considerations like barrier protection and regulatory compliance. This field faces challenges such as material compatibility, regulatory adherence,...

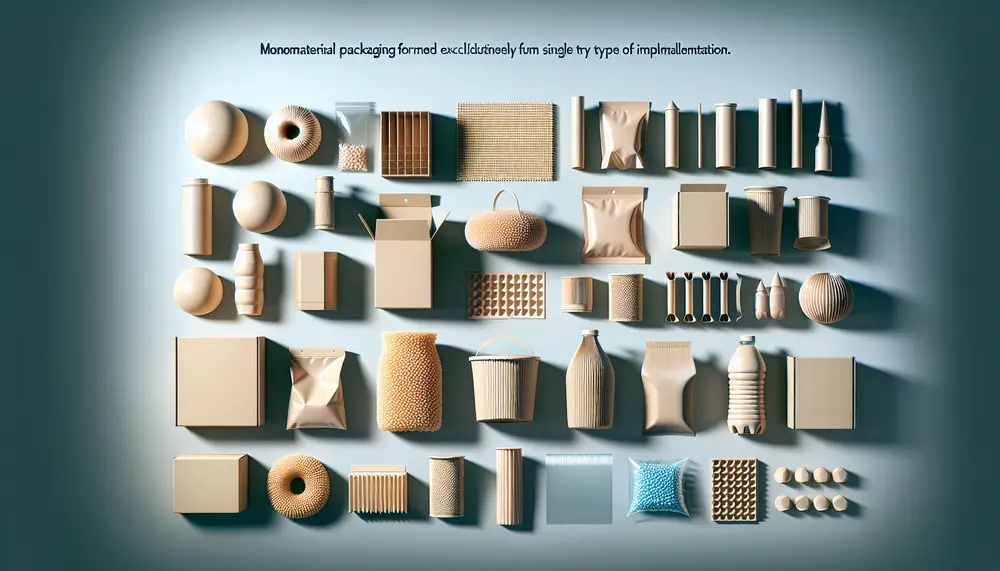

Monomaterial packaging, made from a single material for improved recyclability and production efficiency, faces challenges in maintaining product protection while research continues to develop suitable materials. The shift towards monomaterials aids the environment by reducing carbon footprints and waste, streamlining...

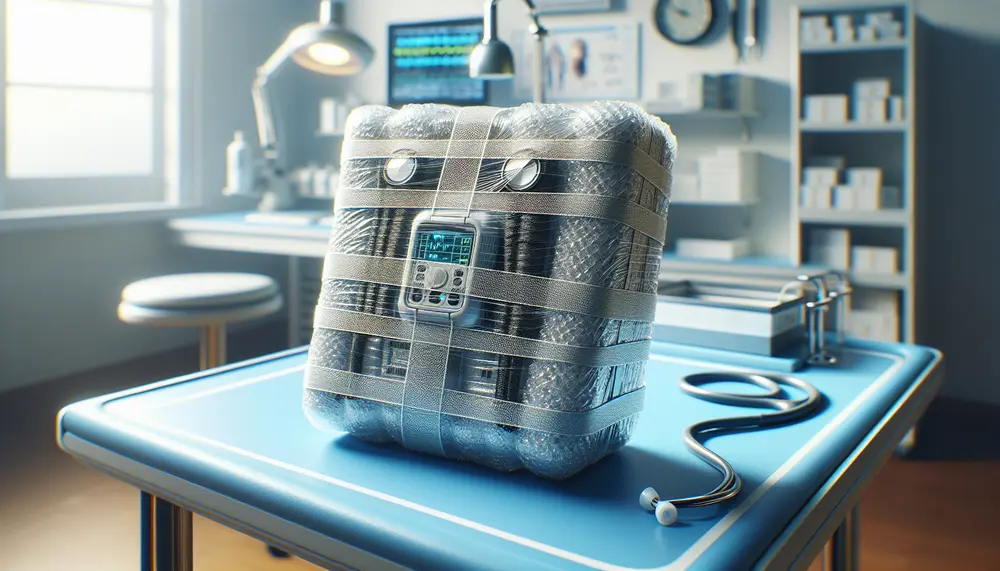

Protective packaging for medical devices is essential to ensure their safety, integrity, and sterility during transportation and storage. It involves selecting appropriate materials that can withstand sterilization processes while providing physical protection and maintaining regulatory compliance....

Visual storytelling on SlideShare revolutionizes pharmaceutical packaging communication by combining engaging visuals with concise content, simplifying complex concepts like material innovation, compliance, and design functionality. This approach fosters global collaboration, enhances understanding through interactive learning tools, and showcases key elements...

Protective packaging for electronics is essential to safeguard devices from damage during shipping, handling, and storage by using materials like anti-static bags, foam inserts, bubble wrap, desiccants, and aluminum barrier films. These solutions prevent physical damage, moisture intrusion, static electricity...

Pharmaceutical packaging is crucial for maintaining the safety, efficacy, and integrity of medications by protecting them from external factors like moisture and light, enhancing patient compliance with user-friendly designs such as dosing calendars, and extending product shelf life. Various types...

Flat bags are essential, cost-effective packaging with a space-saving design used across industries and can be made from sustainable materials. They offer customization for branding, durability against environmental factors, and versatility in applications ranging from fashion to food industry while...

Pharmaceutical packaging solutions are essential for ensuring the safety, efficacy, and stability of medications by protecting them from environmental factors, contamination, and physical damage. The industry is evolving with advanced materials like blister packs and smart technologies such as RFID...

Protective packaging manufacturers design and produce solutions to safeguard products from damage, contamination, and environmental factors during transportation and storage. They work with various industries to create customized packaging using materials like foam, bubble wrap, corrugated cardboard, plastic films, barrier...

The pharmaceutical industry is evolving with innovations in packaging that enhance patient safety, improve drug efficacy, and meet regulatory requirements. Key advancements include smart blister packs for tracking medication adherence, high-barrier materials for protection against environmental factors, tamper-evident bottle features,...

Pharmaceutical packaging is essential for protecting medications, ensuring safety and efficacy through materials like glass and plastics, and adhering to strict regulatory standards. Innovations in the field include biodegradable polymers and smart packaging technologies that enhance drug protection and environmental...

Snack packaging is crucial for product protection, convenience, and brand communication; innovations in design and materials cater to consumer lifestyles and preferences. The evolution of snack packaging reflects a shift towards user-friendly features, sustainability, and technological advancements that balance convenience...