Automatic

Automatic

Automatic in Packaging

In the world of packaging, the term automatic refers to machinery and systems that operate without human intervention. These machines streamline the packaging process, making it faster and more efficient.

How Automatic Packaging Works

Automatic packaging machines perform tasks such as filling, sealing, labeling, and wrapping. They use sensors and software to ensure accuracy and consistency. For example, an automatic filling machine can measure and dispense the exact amount of product into each container.

Benefits of Automatic Packaging

Using automatic packaging systems offers several advantages. First, it increases productivity by speeding up the packaging process. Second, it reduces labor costs since fewer workers are needed. Third, it improves quality control by minimizing human error.

Types of Automatic Packaging Machines

There are various types of automatic packaging machines. Some common ones include automatic filling machines, automatic sealing machines, and automatic labeling machines. Each type is designed for specific tasks and industries.

Examples of Automatic Packaging

Consider a beverage company that uses an automatic bottling line. The system fills bottles with liquid, caps them, and applies labels—all without human touch. This ensures a high level of efficiency and consistency.

Conclusion

Automatic packaging is a key component in modern manufacturing. It enhances efficiency, reduces costs, and ensures consistent quality. Understanding how automatic systems work can help businesses choose the right solutions for their packaging needs.

Blog Posts with the term: Automatic

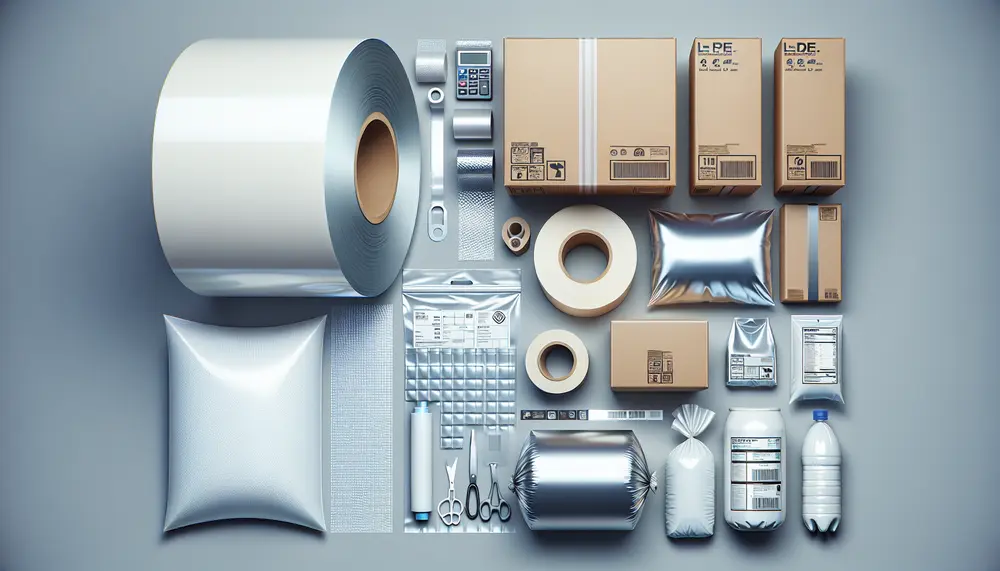

The packaging industry's value chain encompasses material procurement, design and development, manufacturing, distribution, marketing, sales, and after-sales service. Challenges such as environmental regulations, consumer demands for sustainability, cost volatility, technological advances, globalization issues, and supply chain complexity necessitate strategic planning...

The packaging and technology revolution is transforming product protection, preservation, and presentation through intelligent systems, AR/VR experiences, digital printing for customization, with a focus on data security in smart packaging solutions. This intersection of fields offers innovation opportunities across industries. Technology's...

Pharmaceutical packaging for export requires strict adherence to international regulations set by global regulatory bodies like WHO, ICH, EMA, FDA, and PMDA to ensure safety and quality. Key regulations include Good Manufacturing Practice (GMP), ISO standards, serialization systems, labeling requirements,...

Pharmaceutical packaging defects can compromise product integrity, posing health risks and financial losses; common defects include uneven sealing surfaces, raised seams, excess bottom flash, uneven sides, foreign material presence, and incorrect material specifications. Identifying causes such as material quality issues,...

Stretch film is a highly elastic plastic material used to wrap and secure items, particularly on pallets, for transport or storage. It provides stability, protection from damage and moisture, comes in various types for different applications, but poses environmental concerns...

The article discusses the importance of selecting high-quality pharmaceutical packaging equipment manufacturers and profiles several leading companies in this sector. It highlights ACIC Pharmaceuticals, Körber AG, IDEX Corporation, Bosch Group, and Marchesini Group S.p.A., emphasizing their innovative solutions, global reach,...

Advanced packaging machines enhance efficiency and productivity in modern production lines by automating tasks, ensuring precision, and enabling cost savings. They are crucial for businesses to stay competitive and meet industry standards. High-efficiency packaging machines feature user-friendly interfaces, modular designs, precise...

Food packaging is essential for protecting food, preserving quality, and providing information; it's made from various materials including eco-friendly options and plays a key role in marketing. Current trends focus on convenience, minimalism, antimicrobial properties, and sustainability. Innovative food packaging offers...

Protection pack sizing is essential for ensuring products reach their destination safely, optimizing shipping costs, and enhancing customer satisfaction. This guide covers the basics of protection pack sizing, key influencing factors such as product dimensions and weight, accurate measurement techniques,...

LDPE film is a flexible, transparent thermoplastic used extensively in packaging for its chemical resistance and moisture barrier properties, which are crucial across industries like food, pharmaceuticals, and agriculture. It stands out due to its recyclability and balance of protection,...

A packing slip is a crucial document in e-commerce that lists the items included in a package, serving as a communication tool between sellers and buyers. It helps manage goods leaving the warehouse, enables customers to verify received items against...

Roll bags, made from HDPE for strength and moisture resistance, are versatile and convenient for storage and packaging in various settings due to their easy dispensing design. They're portable, clear for labeling, resilient against leaks, fitting into roll bag dispensers...

Packaging automation refers to the use of automated machinery and robotics for packaging products, increasing efficiency, reducing costs, and minimizing human error. The evolution of this technology has been driven by rising labor costs, increased demand for goods and services,...

Packaging tape dispensers are vital for efficient box sealing in various industries, offering speed and security during transportation. They range from simple handheld models to complex industrial machines, with features like tape compatibility, blade quality, ergonomic design, adjustable tension, and...