Aseptic packaging

Aseptic packaging

Aseptic Packaging

Aseptic packaging is a method used to keep food and beverages fresh for a long time. This process involves sterilizing the product and the packaging separately. Once both are sterile, they are combined in a clean environment.

How Does Aseptic Packaging Work?

The first step in aseptic packaging is to sterilize the food or drink. This can be done using heat, chemicals, or other methods. Next, the packaging material is sterilized, often using heat or UV light. Finally, the product is filled into the sterile package in a controlled, germ-free environment.

Benefits of Aseptic Packaging

Aseptic packaging offers many benefits. It extends the shelf life of products without the need for preservatives. It also allows products to be stored at room temperature, which saves on refrigeration costs. Additionally, it helps maintain the flavor, color, and nutritional value of the product.

Common Uses of Aseptic Packaging

You can find aseptic packaging in many everyday products. Common examples include milk, juice, soups, and sauces. This method is also used for pharmaceuticals and other sterile products.

Environmental Impact

Aseptic packaging can be more environmentally friendly than other methods. It often uses less energy and produces less waste. However, it's important to recycle the packaging properly to minimize its environmental footprint.

Blog Posts with the term: Aseptic packaging

This article discusses the evolution and variety of milk packaging materials, highlighting their role in preserving milk's freshness, taste, and nutrition. It covers historical advancements from glass bottles to modern sustainable options, examining each material's benefits and drawbacks for consumers...

Glass is the preferred material for pharmaceutical packaging due to its chemical inertness, excellent barrier properties against gases and moisture, non-porous surface, recyclability, aesthetic appeal, temperature resistance, and light protection capabilities. These attributes ensure that medications remain pure, stable, effective...

The article discusses the significant role of packaging giants in driving innovation and efficiency within the industry, focusing on their strategic importance, market dominance across various materials, and efforts to meet changing demands with sustainable solutions. It highlights how these...

Understanding packaging box materials is crucial for product presentation, protection, and environmental impact. Material choice affects cost, durability, and sustainability; factors like strength and recyclability must be considered. Paper-based boxes are versatile and range from cardboard to corrugated options with varying...

Pharmaceutical packaging lines are essential in the pharmaceutical industry, ensuring drugs are safely and securely packaged to maintain their integrity and comply with stringent regulations. These systems incorporate advanced technologies like robotics, AI, and track-and-trace systems to enhance operational efficiency...

Pharma-grade packaging is a meticulously designed system that ensures the safety, stability, and usability of medications by protecting them from environmental factors, contamination, and degradation while meeting strict regulatory standards. It incorporates advanced materials, user-friendly features like tamper-evident seals, and...

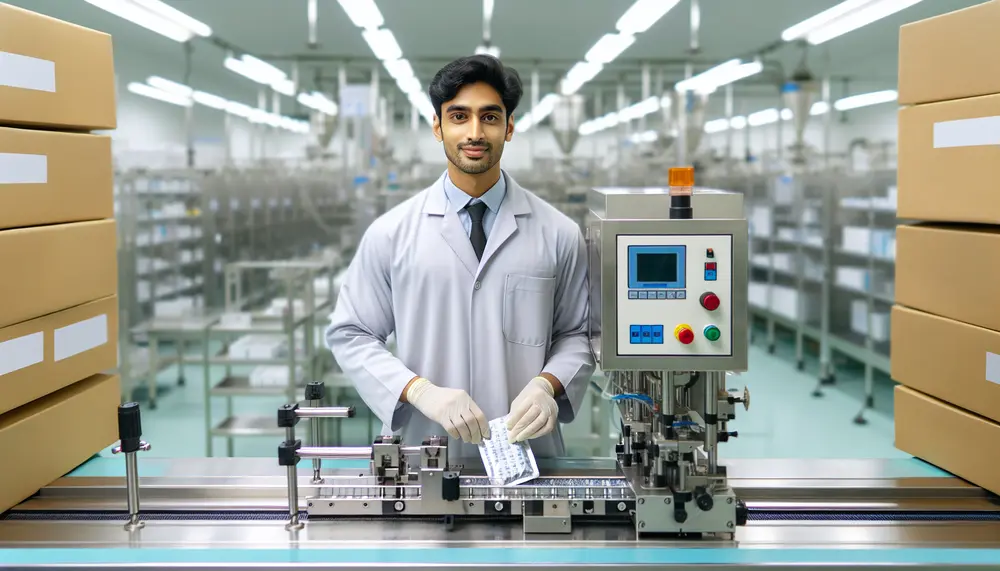

The role of a pharmaceutical packaging operator is vital in ensuring the safety and efficacy of medications by handling the final stage of drug production, which includes operating specialized machinery to package various forms such as tablets and liquids while...

The Pharmaceutical Packaging Exhibition showcased innovations in user-friendly and secure packaging, including smart technologies like NFC chips and QR codes for enhanced tracking and patient engagement. Key trends highlighted were sustainability with eco-friendly materials, digital integration using AR, advanced barrier...

A well-structured Slideshare on packaging materials should use a clear narrative, visual comparisons, and actionable insights to guide viewers in choosing the right material. Each type—glass, metal, plastic, paper/board, composites, or biodegradable options—has unique strengths and weaknesses best matched to...