Table of Contents:

Understanding the Importance of Product Packaging

Product packaging serves as more than just a container for goods. It is a critical element in the customer's journey and decision-making process. Packaging can set the tone for the product inside and affects how the brand is perceived in the marketplace. By combining form and function, effective packaging can add value to the product, catching the eye of potential customers and differentiating it from competitors.

At its core, packaging must keep the product safe and intact throughout its journey from the manufacturer to the end consumer. However, it also plays a vital marketing role. Packaging can entice consumers through aesthetic appeal and tactile experiences, creating a sensory connection with the product. Moreover, it conveys essential information such as usage instructions, ingredients, and nutritional facts, which can be a deciding factor in the purchase.

Advanced packaging strategies take into account the psychological impact of color schemes, typography, and imagery. Understanding the target audience allows brands to design packaging that resonates on a deeper level. For example, minimalistic design might appeal to consumers valuing simplicity, while bright and bold patterns might attract those looking for something fun and exciting.

In conclusion, the packaging of a product is an extension of the product itself and, by extension, the brand. Investing time and resources into understanding and creating quality packaging is not an additional expense but a smart investment into the brand's future success and customer loyalty.

The Design Process: Crafting the Packaging of Your Product

The design process for crafting product packaging is a meticulous journey that blends creativity with technical precision. It begins with a deep understanding of the brand and the story it wants to tell. Designers must consider how the packaging will communicate the product's value proposition and how it will enhance the customer's unboxing experience.

During the design phase, various concept sketches and digital mockups are created. This allows designers to experiment with different shapes, sizes, and layout options. A strong focus is placed on ergonomics and user-friendliness, ensuring that the packaging is easy to handle and manipulate.

Key stages of the design process often include:

- Research and conceptualization, taking into account market trends and consumer behavior.

- Creating initial design drafts and gathering feedback from stakeholders.

- Refining designs and selecting suitable color palettes and fonts.

- Developing prototypes to test the packaging's form, function, and durability.

- Finalizing the design with attention to detail on every aspect, from material finishes to closure mechanisms.

Designers must also consider the technical aspects such as the package's ability to be manufactured efficiently and its structural integrity. They work closely with engineers to calculate the appropriate dimensions and select materials that can withstand the stresses of transportation and storage. Complex designs may involve mathematical equations, represented using symbols and numbers, such as determining the wall thickness for a container (e.g., t = P·r / (2·σ) where t = thickness, P = internal pressure, r = radius, and σ = material stress).

Ultimately, the right combination of aesthetics and functionality in packaging design can lead to increased brand recognition and consumer satisfaction. The design process is a critical step in turning a concept into a product that stands out on the shelf and resonates with consumers.

Pros and Cons of Product Packaging Development

| Advantages | Disadvantages |

|---|---|

| Protection during transit | Potential environmental impact |

| Marketing and branding opportunities | Costs for design and materials |

| Information provision for consumers | Waste generation post-consumer use |

| Shelf appeal and customer attraction | Possible negative perception if over-packaged |

| Improves product lifespan and freshness | May require extensive testing and compliance |

Choosing the Right Materials for Your Packaging Products

Selection of materials for packaging products is a pivotal decision that directly impacts the product's protection, shelf life, and ecological footprint. There exists a wide array of packaging materials, and each comes with its own set of properties, making it suitable for specific applications. The choice hinges on factors such as product compatibility, environmental sustainability, and cost-effectiveness.

Common materials include plastics, glass, metals, and an assortment of paper and cardboard products. Plastics offer versatility and durability, with options like PET being popular for its clarity and recyclability. Glass provides an excellent barrier against contaminants but at the expense of higher weight and fragility. Metals, such as aluminum, are chosen for their strength and recyclability, especially in the food and beverage industry.

Meanwhile, the surge in eco-conscious consumerism has steered the focus towards materials that offer a reduced environmental impact, such as:

- Biodegradable plastics that break down more rapidly once discarded.

- Post-consumer recycled content that reduces the need for virgin materials.

- Plant-based materials like starch-based packing peanuts and molded pulp.

Technological advancements also play a key role. For instance, active packaging materials that can extend shelf life or indicate spoilage are making headways in food industries. Innovations in barrier coatings are improving the protective qualities of traditionally weaker materials like paper, sometimes using nanotechnology applications symbolized as thin layers (

Packaging plays a pivotal role in marketing by serving as a visual and tactile medium to attract and inform consumers about a product. It enhances brand recognition, differentiation from competitors, and can significantly influence the consumer's purchase decision by offering a promising unboxing experience and reflecting the brand's values.

Sustainability in product packaging is increasingly important as consumers become more environmentally conscious. Sustainable packaging strategies strive to minimize negative environmental impacts by using recyclable, biodegradable, or renewable materials, reducing waste and optimizing the use of resources throughout the product's lifecycle.

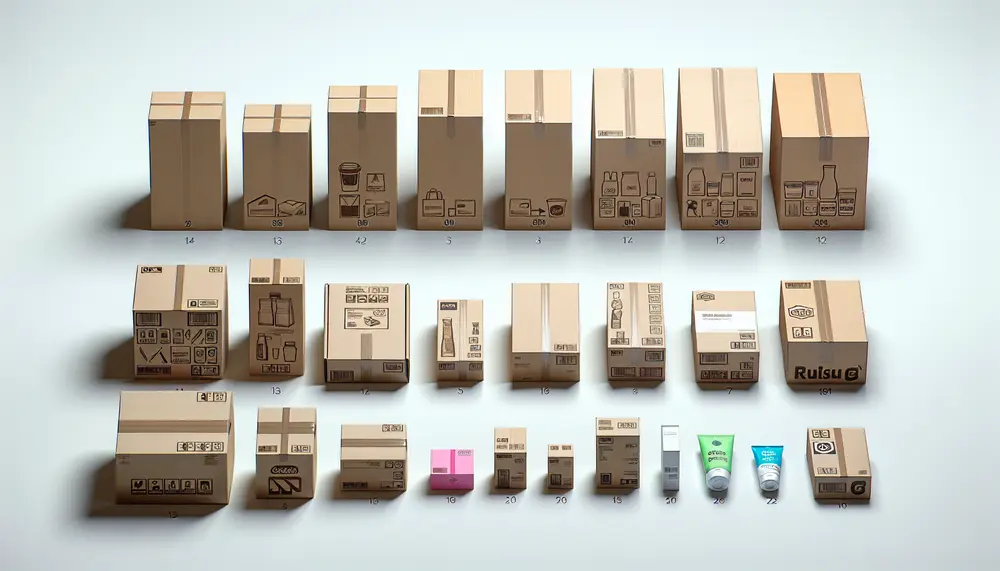

Product packaging can be categorized into three levels: primary packaging, which directly contains and protects the product; secondary packaging, which groups primary packages for better handling and protection during transport; and tertiary packaging, used for bulk handling and large-scale shipments like corrugated boxes on pallets.

The packaging design and prototyping stages are essential for visualizing and testing the packaging's aesthetics and functionality before mass production. Prototyping allows designers and stakeholders to assess and refine the packaging, ensuring it meets the desired standards of performance, customer appeal, and manufacturability.

Key factors in selecting packaging materials include product compatibility and protection, cost-effectiveness, environmental sustainability, and regulatory compliance. Brands must evaluate the trade-offs between material functionality, consumer preferences for sustainable packaging, and reaching a balance that aligns with their overall brand strategy and values.

Frequently Asked Questions on Product Packaging Development

What is the role of packaging in marketing a product?

How important is sustainability in product packaging?

What are the different levels of packaging?

How do packaging design and prototyping contribute to the development process?

What are the key factors to consider in packaging materials selection?